Liquid Filling Machine, Paste Filling Machine, Filling Machine

Liquid Filling Machine, Paste Filling Machine, Filling Machine

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Liquid Filling Machine, Paste Filling Machine, Filling Machine

Call:- 9713032266 / 7089062266

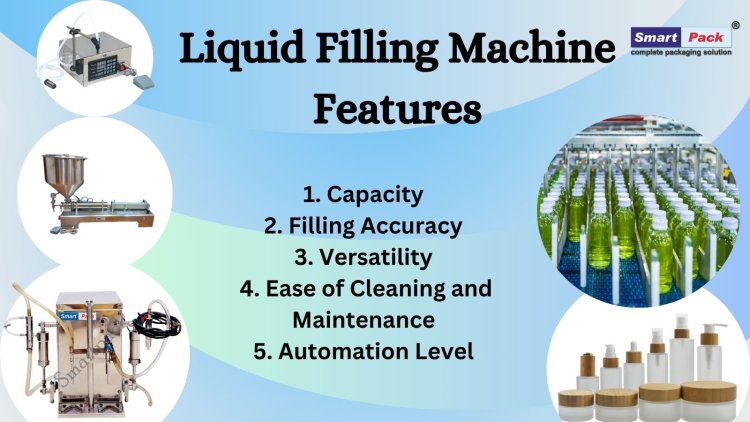

Are you looking for information about a filling machine? Filling machines are used in various industries to fill containers with liquids, powders, or other substances. They come in different types, including gravity fillers, piston fillers, and vacuum fillers, among others. What specific information are you seeking about filling machines?

The Importance of Filling Machine Maintenance

Maintaining filling machines is crucial for several reasons:

Consistency in Production: Regular maintenance ensures that filling machines operate at optimal efficiency, maintaining consistent filling volumes and preventing variations in product quality. This consistency is vital for meeting customer expectations and regulatory standards.

Reduced Downtime: Scheduled maintenance helps identify and address potential issues before they lead to breakdowns or malfunctions. This proactive approach minimizes unplanned downtime, keeping production lines running smoothly and maximizing productivity.

Extended Equipment Lifespan: Proper maintenance practices, such as cleaning, lubrication, and parts replacement, help prevent premature wear and tear on filling machine components. By extending the lifespan of equipment, businesses can avoid the cost of frequent replacements and upgrades.

Cost Savings: Investing in maintenance can save money in the long run by reducing repair costs, minimizing production disruptions, and optimizing energy efficiency. Additionally, proactive maintenance can prevent costly emergencies and mitigate the risk of product recalls due to equipment-related issues.

Safety and Compliance: Regular maintenance ensures that filling machines operate safely and comply with relevant regulations and industry standards. Malfunctioning equipment can pose safety hazards to workers and consumers, as well as lead to regulatory fines and penalties for non-compliance.

Quality Assurance: Properly maintained filling machines help maintain product integrity by preventing contamination, leaks, or other quality issues that may arise from equipment malfunctions. This is especially important in industries with stringent quality control requirements, such as food, pharmaceuticals, and cosmetics.