What is CNC Plasma Cutting Machine and its function?

The price of plasma cutters can vary significantly depending on the features needed, just like the price of most CNC machines. However, they are typically the most affordable choice when purchasing a profile cutting machine. The most expensive alternative is using a laser cutting machine, with waterjets falling somewhere in the between.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

You’ve come to the correct place if looking for more details regarding how a CNC plasma cutting machine operates since our team has you covered! As a top provider of fabrication equipment, Pusaan India is honoured to provide some of the best CNC plasma cutting machines available. We’ll examine these machines’ workings in more detail and go over some of their advantages in this blog post. Find out more and get in touch to locate plasma cutters and other fabrication tools right away!

What Is a CNC Plasma Cutter?

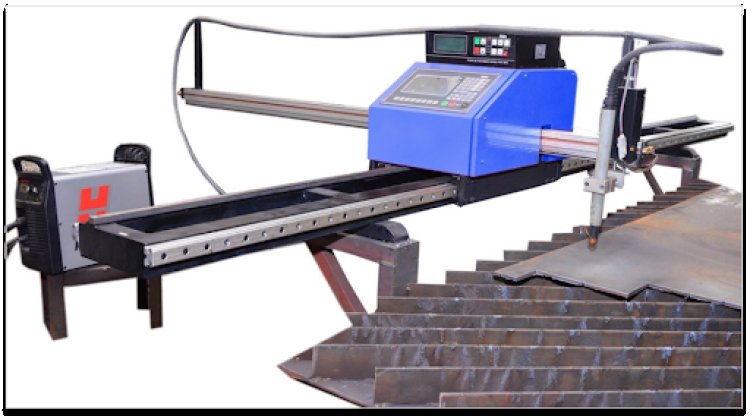

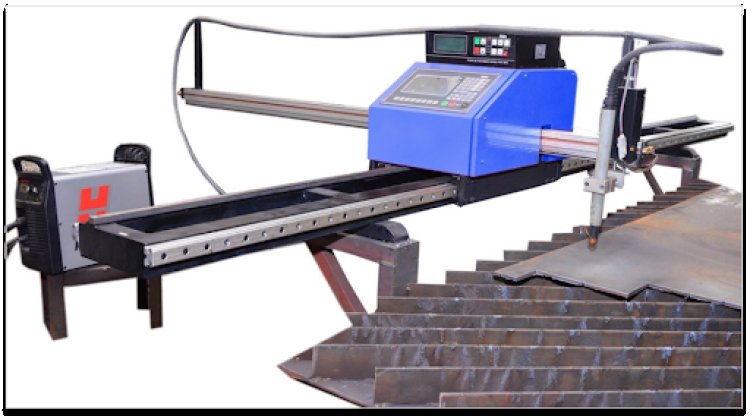

A CNC plasma cutter is a computer-controlled machine that cuts through conductive materials like steel, aluminium, and brass using a high-powered plasma torch. Metal may be cut precisely with plasma cutting, and CNC technology makes it easy to achieve consistent results with no operator involvement.

How Does a CNC Plasma Cutting Machine Work?

A high-pressure stream of ionised gas is used by CNC plasma cutters to cut through metal. The CNC controller manages the movement of the plasma torch, which is connected to an electrical power supply. An electric arc is produced between the electrode and the torch’s nozzle when the trigger is pulled. The gas is ionised by this arc, producing plasma. After then, the torch is used to force the plasma out at a fast speed, which simultaneously cuts through the metal.