Disposable Box Making Machines: Transforming the Packaging Industry

Discover how disposable box-making machines are transforming the packaging industry by providing efficient and eco-friendly solutions for producing high-quality disposable packaging. Learn about the workings, benefits, and applications of these machines, including their role in food and beverage, retail, healthcare, and e-commerce sectors. As a sustainable packaging solution, these machines offer businesses the ability to produce customized packaging quickly and cost-effectively, meeting the growing demand for environmentally friendly packaging options.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

In the fast-paced world of consumer goods, packaging plays a crucial role in ensuring product safety, convenience, and sustainability. Disposable box-making machines have emerged as a game-changing technology in the packaging industry, offering efficient solutions for producing high-quality, eco-friendly packaging. This article delves into the workings, benefits, and applications of disposable box-making machines and their impact on the packaging sector.

What is a Disposable Box Making Machine?

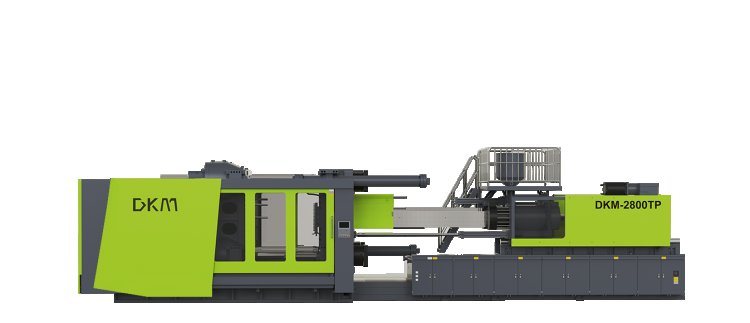

A disposable box-making machine is a piece of equipment designed to manufacture various types of disposable boxes and containers. These machines are capable of producing a wide range of packaging products, including food boxes, takeout containers, and other one-time-use items. They are designed to handle materials such as paper, cardboard, and biodegradable plastics, making them an essential tool for sustainable packaging production.

How Do Disposable Box Making Machines Work?

Disposable box-making machines operate through several key processes:

-

Material Feeding: The machine is equipped with a feeding system that automatically supplies the raw materials, such as paper or cardboard sheets, into the machine.

-

Cutting and Creasing: The materials are precisely cut and creased into specific shapes using advanced die-cutting technology. This ensures that the boxes are formed accurately with clean edges and proper folding lines.

-

Forming and Gluing: The cut and creased materials are then folded into the desired box shape. Gluing mechanisms apply adhesive to secure the box structure, ensuring durability and stability.

-

Printing and Finishing: Some machines include printing capabilities, allowing for branding and labeling directly on the boxes. Additional finishing touches, such as varnishing or embossing, can be applied to enhance the appearance and functionality of the packaging.

-

Stacking and Ejection: The completed boxes are automatically stacked and ejected from the machine, ready for packaging and distribution.

Benefits of Disposable Box Making Machines

Disposable box-making machines offer a multitude of advantages:

-

Efficiency: These machines can produce large quantities of boxes quickly, reducing production time and labor costs.

-

Customization: Advanced machines offer options for customization, allowing businesses to produce packaging that meets specific design and size requirements.

-

Sustainability: By using eco-friendly materials and minimizing waste, these machines contribute to sustainable packaging practices.

-

Cost-Effectiveness: Automating the production process reduces the need for manual labor, lowering overall production costs.

-

Quality and Consistency: The precision of modern machines ensures high-quality boxes with consistent dimensions and strength.

Applications of Disposable Box Making Machines

Disposable box-making machines are used across various industries, including:

-

Food and Beverage: These machines produce takeout boxes, meal trays, and drink holders for restaurants, cafes, and catering services.

-

Retail: They manufacture packaging for products such as clothing, electronics, and household items, providing secure and attractive packaging solutions.

-

Healthcare: Disposable boxes are used for packaging medical supplies, ensuring hygiene and safety.

-

E-commerce: With the rise of online shopping, these machines produce shipping boxes and packaging materials for e-commerce businesses.

The Future of Disposable Box Making Machines

As the demand for sustainable and efficient packaging solutions continues to grow, disposable box-making machines are poised to play a vital role in the future of the packaging industry. Technological advancements will further enhance machine capabilities, offering more innovative and eco-friendly packaging options.

Conclusion

Disposable box-making machines have revolutionized the packaging industry by providing efficient, sustainable, and cost-effective solutions for producing high-quality packaging. As businesses strive to meet consumer demands for environmentally friendly products, these machines are becoming indispensable tools in achieving packaging excellence.