The Groundwork Hero: Polyester Geogrids - Strength Below the Surface

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Introduction

In the realm of modern construction and civil engineering, the quest for materials that combine strength, durability, and sustainability is ever-present. Polyester geogrids have emerged as a groundbreaking solution, providing exceptional reinforcement to various infrastructure projects. Singhal Industries, a leading manufacturer of flexible packaging products, is at the forefront of this innovation. This blog will delve into the properties, benefits, applications, and environmental impact of polyester geogrids, showcasing their role in creating a strong and sustainable foundation for construction projects.

What are Polyester Geogrids?

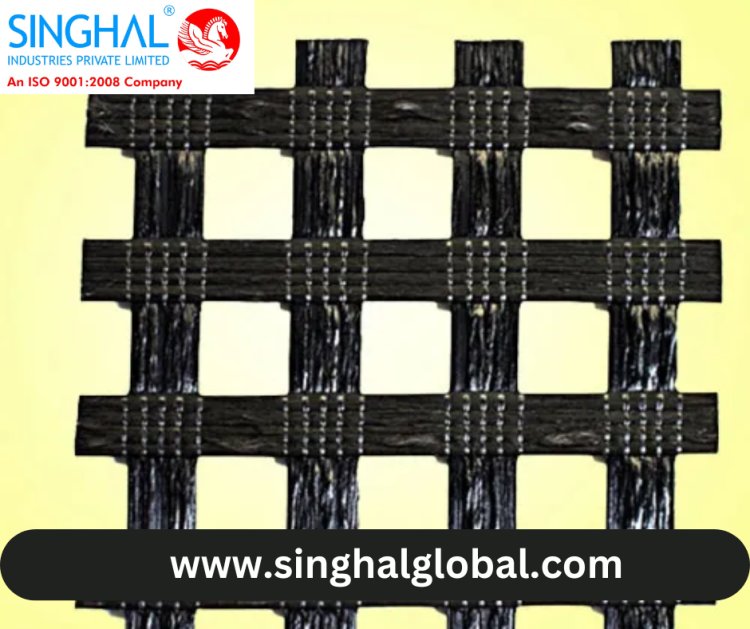

Polyester geogrids are high-strength geosynthetic materials made from polyester fibers. These grids are used to reinforce soils and other materials in construction projects. They consist of a network of intersecting ribs and apertures, creating a mesh-like structure that provides tensile strength and stability to the soil or aggregate materials they are used with.

Key Benefits of Polyester Geogrids

1. High Tensile Strength

One of the primary benefits of polyester geogrids is their high tensile strength. This property allows them to effectively distribute loads and stresses over a larger area, reducing the risk of structural failure. This makes them ideal for applications where high load-bearing capacity is required, such as roadways, retaining walls, and embankments.

2. Durability and Long Service Life

Polyester geogrids are known for their durability and long service life. They are resistant to various environmental factors, including UV radiation, chemicals, and biological degradation. This ensures that they maintain their structural integrity over extended periods, even in harsh conditions.

3. Flexibility and Adaptability

Unlike some other reinforcement materials, polyester geogrids are flexible and can adapt to different soil conditions and terrain. This flexibility allows them to be used in a wide range of applications, from flat terrains to steep slopes and uneven ground.

4. Cost-Effectiveness

The use of polyester geogrids can lead to significant cost savings in construction projects. By improving soil stability and load distribution, they reduce the need for extensive excavation and the use of expensive fill materials. This not only lowers material costs but also shortens construction time, leading to overall project cost savings.

5. Environmental Sustainability

Singhal Industries is committed to sustainability, and polyester geogrids align perfectly with this vision. The use of geogrids reduces the need for natural aggregate materials, conserving natural resources. Additionally, their durability and long service life minimize the environmental impact of construction projects, contributing to a more sustainable built environment.

Applications of Polyester Geogrids

1. Roadway Construction

Polypropylene geogrid suppliers are extensively used in roadway construction to improve the structural integrity of roads and highways. They reinforce the subgrade and base layers, preventing rutting and extending the lifespan of the roadway.

a. Subgrade Stabilization

By reinforcing the subgrade, polyester geogrids enhance the load-bearing capacity of the soil, reducing deformation and ensuring a stable foundation for the roadway. This is particularly important in areas with weak or variable soil conditions.

b. Asphalt Reinforcement

Polyester geogrids are also used in asphalt reinforcement to prevent cracking and extend the service life of the pavement. They distribute traffic loads more evenly, reducing stress on the asphalt layer and minimizing maintenance requirements.

2. Retaining Walls and Slopes

In retaining wall and slope construction, polyester geogrids provide essential reinforcement to prevent soil erosion and structural failure. Their high tensile strength and flexibility make them ideal for these applications.

a. Soil Reinforcement

Polyester geogrids are used to reinforce the soil behind retaining walls and slopes, increasing their stability and preventing landslides. This is especially important in areas prone to heavy rainfall or seismic activity.

b. Erosion Control

In addition to providing structural support, polyester geogrids help control erosion by stabilizing the soil and preventing it from being washed away. This is particularly beneficial in coastal and riverbank areas.

3. Embankments and Foundations

Polyester geogrids are used in the construction of embankments and foundations to enhance stability and load-bearing capacity. They provide reinforcement to the underlying soil, ensuring a solid and stable base for the structure.

a. Embankment Reinforcement

In embankment construction, polyester geogrids are used to reinforce the fill material, preventing settlement and deformation. This is crucial for the stability and longevity of the embankment.

b. Foundation Support

Polyester geogrids are also used in foundation construction to improve the load-bearing capacity of the soil and prevent settlement. This ensures a stable foundation for buildings and other structures.

4. Landfill and Waste Management

In landfill and waste management applications, polyester geogrids provide essential reinforcement to prevent slope failure and enhance the stability of waste containment structures.

a. Slope Stabilization

Polyester geogrids are used to stabilize the slopes of landfills, preventing erosion and slope failure. This is crucial for maintaining the integrity of the landfill and preventing environmental contamination.

b. Liner Reinforcement

Polyester geogrids are also used to reinforce landfill liners, ensuring they remain intact and prevent the leakage of hazardous materials. This is essential for protecting the surrounding environment from contamination.

5. Mining and Quarrying

In mining and quarrying operations, polyester geogrids provide essential reinforcement to improve the stability of haul roads, stockpile areas, and waste dumps.

a. Haul Road Reinforcement

Polyester geogrids are used to reinforce haul roads in mining operations, ensuring they remain stable and capable of supporting heavy equipment. This reduces maintenance requirements and improves operational efficiency.

b. Stockpile and Waste Dump Stabilization

In stockpile and waste dump areas, polyester geogrids provide essential reinforcement to prevent slope failure and ensure the stability of the material. This is crucial for maintaining safe and efficient operations.

Environmental Impact of Polyester Geogrids

Resource Conservation

The use of polyester geogrids helps conserve natural resources by reducing the need for natural aggregate materials. By reinforcing the soil and improving its load-bearing capacity, geogrids allow for the use of locally available materials, minimizing the need for extensive excavation and transportation of aggregates.

Reduced Carbon Footprint

Polyester geogrids contribute to a reduced carbon footprint in construction projects. Their lightweight nature reduces transportation emissions, and their ability to improve soil stability and load distribution reduces the need for additional construction materials. This leads to lower overall emissions and a more sustainable construction process.

Longevity and Durability

The durability and long service life of polyester geogrids minimize the environmental impact of construction projects. Their resistance to environmental factors ensures they maintain their structural integrity over extended periods, reducing the need for frequent replacements and repairs. This contributes to a more sustainable built environment.

Singhal Industries: A Commitment to Quality and Sustainability

Singhal Industries has established itself as a leader in the flexible packaging industry by consistently delivering high-quality products that meet the diverse needs of their customers. The company's commitment to innovation and sustainability is evident in their range of polyester geogrids, which are designed to offer superior performance and environmental benefits.

Advanced Manufacturing Techniques

Singhal Industries employs advanced manufacturing techniques to produce polyester geogrids that meet the highest standards of quality and durability. The use of state-of-the-art machinery and stringent quality control measures ensures that every geogrid meets the specific requirements of the intended application.

Customization Options

Understanding that different projects have unique needs, Singhal Industries offers customization options for their pol Polyester geogrid Manufacturers meet their specific requirements. Additionally, Singhal Industries provides expert technical support to help customers select the right geogrid for their application.

Sustainable Practices

Singhal Industries is committed to sustainable practices throughout their operations. This commitment extends to their choice of materials, manufacturing processes, and end-of-life solutions for their products. By prioritizing sustainability, Singhal Industries not only meets the demands of eco-conscious consumers but also contributes to a healthier planet.

Conclusion

Polyester geogrid india from Singhal Industries represent the perfect blend of strength, durability, and environmental sustainability. Their wide range of applications, coupled with their exceptional performance and eco-friendly properties, make them an ideal choice for construction and civil engineering projects. As industries continue to seek sustainable and efficient solutions, polyester geogrids stand out as a reliable and innovative option. Singhal Industries' dedication to quality and sustainability ensures that they remain at the forefront of this geosynthetic revolution, providing products that not only meet but exceed customer expectations.

In summary, polyester geogrids are a game-changer in the world of construction and civil engineering. Their high tensile strength, durability, flexibility, and environmental benefits make them a preferred choice for a variety of applications. With Singhal Industries leading the charge, the future of polyester geogrids looks bright, promising a more sustainable and resilient built environment for all.

FAQS

1. What are polyester geogrids?

Polyester geogrids are geosynthetic materials made from high-strength polyester fibers. They are used to reinforce soil and provide stability in various construction and civil engineering applications.

2. What are the main benefits of using polyester geogrids?

Polyester geogrids offer high tensile strength, durability, and flexibility. They improve soil stability, prevent erosion, and extend the lifespan of infrastructure projects such as roads, retaining walls, and embankments.

3. Where are polyester geogrids commonly used?

Polyester geogrids are commonly used in road construction, retaining walls, embankments, slope stabilization, landfill liners, mining operations, and other civil engineering projects that require soil reinforcement and structural stability.

4. Are polyester geogrids environmentally friendly?

Yes, polyester geogrids are environmentally friendly. They contribute to sustainability by reducing the need for natural aggregate materials, minimizing excavation, and offering long-term durability that reduces the frequency of repairs and replacements.

5. Can polyester geogrids be customized for specific projects?

Yes, polyester geogrids can be customized in terms of strength, aperture size, and dimensions to suit the specific requirements of different construction projects. Singhal Industries offers customization options to meet the unique needs of their customers.