PP Spunbond Nonwoven Fabric: The Future of Versatile and Durable Textiles

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Introduction

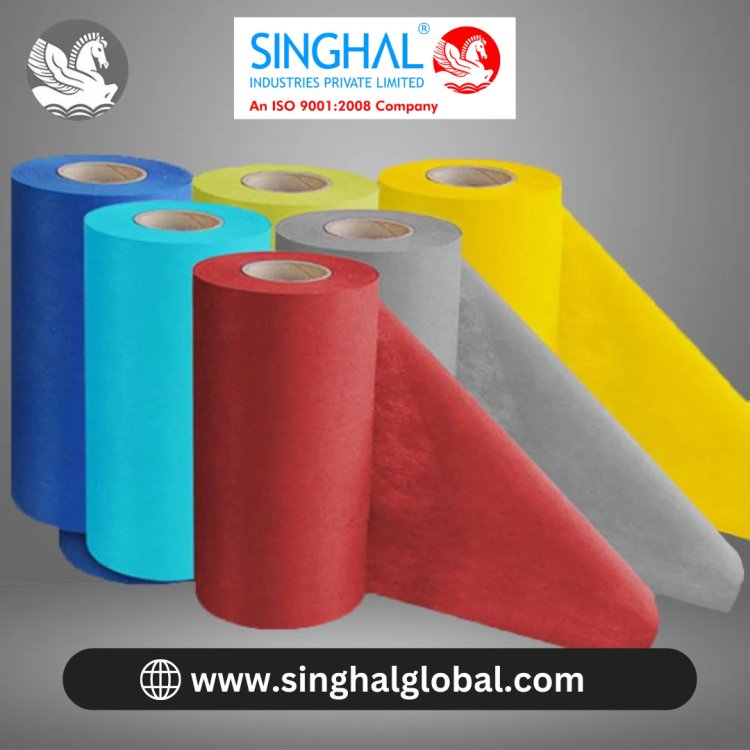

In the rapidly evolving world of textiles, one material stands out for its remarkable versatility, durability, and eco-friendliness: PP (polypropylene) spunbond nonwoven fabric. As a leading manufacturer of flexible packaging products, Singhal Industries is at the forefront of producing high-quality PP spunbond nonwoven fabric that meets the diverse needs of industries ranging from medical to agriculture. This blog delves into the unique attributes, manufacturing process, applications, and benefits of PP spunbond nonwoven fabric, highlighting why it is considered the future of textiles.

What is PP Spunbond Nonwoven Fabric?

PP spunbond nonwoven fabric is a type of textile made from polypropylene, a thermoplastic polymer. Unlike traditional woven fabrics, Spunbond Exporter in Ahmedabad are not created by weaving or knitting fibers together. Instead, they are made by bonding fibers together using chemical, mechanical, heat, or solvent treatment. The spunbond process involves extruding polypropylene polymer into continuous filaments, which are then laid down randomly to form a web. This web is bonded together using heat and pressure to create a strong, flexible, and uniform fabric.

The Manufacturing Process

The production of PP spunbond nonwoven fabric involves several key steps:

-

Polymer Extrusion: Polypropylene granules are melted and extruded through a spinneret to form continuous filaments. These filaments are cooled and solidified as they are extruded.

-

Web Formation: The continuous filaments are laid down randomly onto a conveyor belt to form a web. This web formation can be controlled to achieve different fabric weights and properties.

-

Bonding: The web is passed through a series of calender rollers that apply heat and pressure to bond the filaments together. This process creates a strong, cohesive fabric.

-

Finishing: The bonded fabric is then treated with various finishing processes, such as printing, dyeing, or adding functional treatments (e.g., water repellency, flame retardancy) to enhance its properties and performance.

Key Characteristics of PP Spunbond Nonwoven Fabric

-

Strength and Durability: The continuous filament structure of PP spunbond nonwoven fabric provides exceptional tensile strength and durability. This makes it suitable for applications requiring robust and long-lasting materials.

-

Lightweight: Despite its strength, PP spunbond nonwoven fabric is lightweight, making it easy to handle and transport. This characteristic is particularly valuable in applications where weight reduction is critical.

-

Breathability: The porous structure of the fabric allows air and moisture to pass through, providing breathability. This is essential for applications such as medical gowns and masks, where comfort and air permeability are crucial.

-

Chemical Resistance: Polypropylene is inherently resistant to many chemicals, solvents, and oils, making PP spunbond nonwoven fabric suitable for use in harsh environments and applications requiring chemical resistance.

-

Eco-Friendliness: PP spunbond nonwoven fabric is recyclable and can be reused multiple times, reducing its environmental impact. Additionally, the production process generates minimal waste, contributing to its sustainability.

-

Customizability: The fabric can be customized in terms of thickness, color, texture, and functional treatments to meet specific requirements. This versatility makes it adaptable to a wide range of applications.

Applications of PP Spunbond Nonwoven Fabric

-

Medical and Healthcare: PP spunbond nonwoven fabric is extensively used in the medical and healthcare industry for making surgical masks, gowns, caps, shoe covers, and other disposable medical products. Its breathability, barrier properties, and resistance to fluids make it ideal for protecting healthcare workers and patients.

-

Agriculture: In agriculture, PP spunbond nonwoven fabric is used for crop protection, weed control, and soil stabilization. It provides a protective barrier against pests, weeds, and extreme weather conditions, promoting healthy plant growth.

-

Geotextiles: PP spunbond nonwoven fabric is used in geotextile applications for soil stabilization, erosion control, and drainage. Its strength and durability make it suitable for use in construction projects, road building, and landscaping.

-

Furniture and Upholstery: The fabric is used in furniture and upholstery for lining, backing, and padding. Its lightweight and durable properties make it an excellent choice for enhancing the comfort and longevity of furniture.

-

Packaging: PP spunbond nonwoven fabric is used in packaging applications for making bags, sacks, and protective covers. Its strength and flexibility provide reliable packaging solutions for various products.

-

Hygiene Products: The fabric is used in the production of hygiene products such as diapers, sanitary napkins, and wipes. Its softness, absorbency, and barrier properties make it suitable for these applications.

-

Automotive: In the automotive industry, PP spunbond nonwoven fabric is used for interior linings, sound insulation, and trunk liners. Its lightweight and durable properties contribute to reducing vehicle weight and improving fuel efficiency.

Benefits of PP Spunbond Nonwoven Fabric

-

Cost-Effective: The production process of PP spunbond nonwoven fabric is efficient and cost-effective, making it an economical choice for various applications. Its long lifespan and reusability further enhance its cost-effectiveness.

-

Hygienic and Safe: The fabric is non-toxic, hypoallergenic, and resistant to bacteria and mold, making it safe for use in medical and hygiene applications. Its disposable nature helps in maintaining hygiene standards.

-

Versatility: The ability to customize the fabric to meet specific requirements makes it versatile and adaptable to a wide range of applications. This versatility ensures that it can be used in diverse industries and settings.

-

Eco-Friendly: PP spunbond nonwoven fabric is recyclable and generates minimal waste during production. Its reusability and long lifespan contribute to reducing environmental impact and promoting sustainability.

-

Enhanced Performance: The fabric can be treated with various functional finishes to enhance its performance. For example, it can be made water-repellent, flame-retardant, or UV-resistant to suit specific applications.

-

Improved Comfort: The fabric's breathability and softness provide comfort in applications such as medical gowns, masks, and hygiene products. Its lightweight nature further enhances user comfort.

Challenges and Solutions

While PP Spunbond non woven fabric manufacturer offers numerous benefits, it also presents certain challenges:

-

Environmental Concerns: Although the fabric is recyclable, improper disposal can contribute to plastic pollution. To address this, it is essential to implement proper waste management practices and encourage recycling.

-

Competition from Other Materials: Other materials such as cotton and polyester also offer advantages in certain applications. However, the superior strength, durability, and cost-effectiveness of PP spunbond nonwoven fabric often make it a more practical choice.

-

Quality Control: Ensuring consistent quality in the manufacturing process is crucial to maintaining the reliability of PP spunbond nonwoven fabric. Strict quality control measures and adherence to industry standards can mitigate this challenge.

Conclusion

PP spunbond nonwoven fabric is a revolutionary material that offers unmatched versatility, durability, and sustainability. As a leading manufacturer of flexible packaging products, Singhal Industries is committed to producing high-quality PP spunbond nonwoven fabric that meets the diverse needs of various industries. Whether in medical, agricultural, or industrial applications, this fabric's unique properties make it a superior choice for modern textiles. By choosing Spunbond nonwoven Supplier India, businesses and consumers can benefit from a cost-effective, environmentally friendly, and high-performance solution that is poised to shape the future of textiles.

FAQS

What is PP spunbond nonwoven fabric?

PP spunbond nonwoven fabric is a type of fabric made from polypropylene fibers that are bonded together using a heat and chemical process, rather than woven together.

What are the key features of PP spunbond nonwoven fabric?

PP spunbond nonwoven fabric is lightweight, breathable, tear-resistant, and non-allergenic. It provides excellent strength and durability while remaining cost-effective.

What are the common applications of PP spunbond nonwoven fabric?

PP spunbond nonwoven fabric is used in various industries such as agriculture (crop covers, weed control), medical (surgical gowns, masks), hygiene (diapers, wipes), and packaging (shopping bags, gift wraps).

How is PP spunbond nonwoven fabric different from other types of nonwovens?

PP spunbond nonwoven fabric is known for its uniformity and strength compared to other nonwoven fabrics. It can be produced in different weights and densities to suit specific application needs.

Is PP spunbond nonwoven fabric environmentally friendly?

Yes, PP spunbond nonwoven fabric is recyclable and can be reused in various applications. It reduces waste compared to traditional textiles and offers a sustainable alternative for disposable products.