PP Spunbond Nonwoven Fabric: Revolutionizing Durability and Versatility in Textiles

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

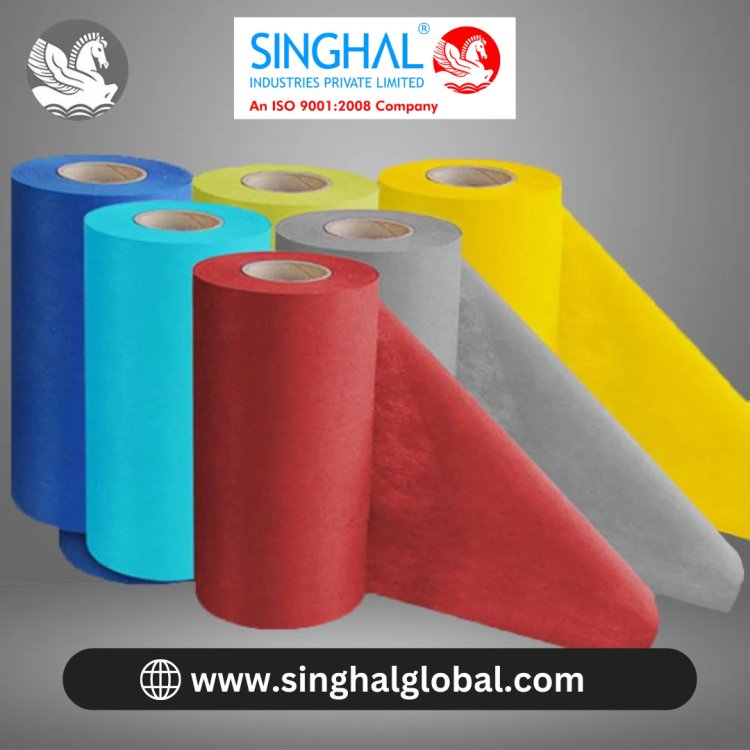

The world of textiles is constantly evolving, driven by innovation and the demand for materials that offer more than just aesthetics. In this ever-changing landscape, PP Spunbond Nonwoven Fabric has emerged as a revolutionary force. Singhal Industries, a leading manufacturer of flexible packaging solutions, is passionate about exploring these innovative materials that redefine possibilities. Spunbond nonwoven Supplier India, with its unique combination of strength, versatility, and eco-friendliness, is rapidly transforming various industries.

A Departure from Tradition: Understanding PP Spunbond

Unlike traditional woven fabrics constructed by interlacing threads, PP Spunbond takes a different approach. Let's delve into its creation process:

- Raw Material: The journey begins with Polypropylene (PP), a readily available and recyclable thermoplastic polymer known for its strength and flexibility.

- Fiber Formation: PP granules are melted and extruded into fine, continuous fibers. Imagine a hot glue gun extruding a long, continuous strand of plastic.

- Web Formation: These fibers are laid down in a web-like structure, creating a uniform layer. Picture a fluffy spiderweb made of plastic fibers.

- Bonding Process: Heat, pressure, or chemical agents bind the fibers together, forming the final nonwoven fabric. This process essentially welds the fibers together to create a cohesive sheet.

This unique production method results in a lightweight, breathable, and surprisingly strong fabric with a vast array of applications.

The Power of Innovation: Unveiling the Benefits of PP Spunbond

Spunbond non woven fabric manufacturer offers a compelling combination of properties that make it a game-changer across various sectors. Here's a closer look at its key advantages:

- Exceptional Durability: Despite its lightweight nature, PP Spunbond boasts impressive strength and tear resistance. This makes it a reliable choice for applications where the fabric needs to withstand regular wear and tear. From agricultural covers to packaging materials, PP Spunbond can handle the job.

- Breathability: The web-like structure of PP Spunbond allows for excellent air permeability. This is particularly beneficial in applications where moisture control is crucial. For instance, PP Spunbond bags used for agricultural products prevent condensation buildup, promoting fresher produce.

- Water Resistance: While not entirely waterproof, PP Spunbond offers a good degree of water resistance. This protects packaged goods from light rain or spills. Additionally, the water-resistant properties can be enhanced through laminations or coatings for specific applications.

- Chemical Resistance: PP Spunbond exhibits resistance to a variety of chemicals, including acids, alkalis, and oils. This makes it suitable for applications involving contact with such substances, promoting safety and reducing the risk of degradation.

- Cost-Effectiveness: Compared to traditional woven fabrics or other nonwoven options, PP Spunbond is a relatively inexpensive material to produce. This translates to cost-effective solutions for manufacturers and consumers alike.

A Spectrum of Possibilities: Unleashing the Versatility of PP Spunbond

The diverse properties of PP Spunbond make it a highly versatile material, applicable across various industries. Here's a glimpse into how PP Spunbond is revolutionizing different sectors:

- Packaging: PP Spunbond is widely used in bags, pouches, and envelopes for packaging a variety of goods, including clothing, food items, and medical supplies. Its lightweight nature also contributes to reduced transportation costs.

- Agriculture: Agricultural covers, weed control mats, and seedling bags are just a few examples of how PP Spunbond benefits the agricultural sector. Breathable covers protect crops from harsh weather while promoting healthy growth. Weed control mats suppress unwanted vegetation, while seedling bags offer a convenient and controlled environment for young plants.

- Medical and Hygiene: Disposable medical gowns, surgical drapes, and wipes often utilize PP Spunbond due to its breathability and hygiene properties. The material also offers a cost-effective option for disposable medical supplies.

- Construction: Underlayments for flooring, roofing membranes, and erosion control fabrics can all be made from Spunbond Exporter in Ahmedabad. Its strength and durability make it suitable for various construction applications.

- Home Furnishings: Reusable shopping bags, furniture covers, and mattress protectors are just a few examples of how PP Spunbond finds its way into our homes. The lightweight and breathable nature makes it ideal for various household applications.

Embracing Sustainability: A Responsible Choice for the Future

At Singhal Industries, sustainability is a core value that guides our product development. PP Spunbond aligns perfectly with this commitment due to several advantages:

- Recyclable: PP Spunbond can be recycled in many locations, minimizing waste and promoting a circular economy. Recycled PP can then be used to create new PP Spunbond products.

FAQS