Oil Country Lathe vs. Standard Lathe: Key Differences

Check out the main differences between oil country lathes and standard lathes in this informative guide. Make an informed decision about which type of lathe is best for your needs!

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

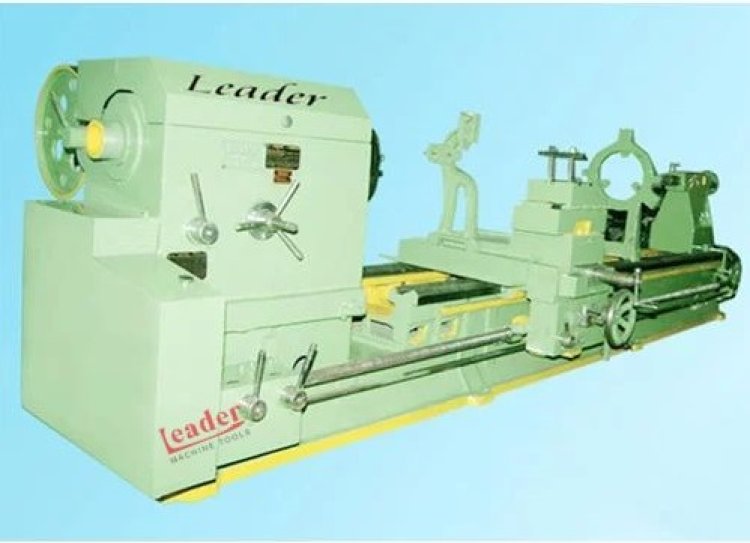

The lathe is a fundamental and versatile tool. Lathes come in various configurations, each designed to handle specific applications and materials. Two of the most common types of lathes are the oil country lathe machine and the standard lathe machine. While they may seem similar at a glance, these two machines have distinct features and capabilities that make them suitable for different manufacturing needs.

In this blog post, we'll explore the key differences between the oil country lathe machine and the standard lathe, helping you understand which one might be the better choice for your metalworking operations.

Defining the Oil Country Lathe Machine

An oil country lathe machine is also called an oilfield lathe or heavy-duty lathe and is a super strong metal shaper built for oil and gas jobs. These extra tough machines can handle big, heavy, and oddly shaped pieces of metal used in finding, getting, and fixing oil and gas.

Key Features of the Oil Country Lathe:

- Larger Capacity: Oil Country Lathes are designed to accommodate larger workpieces, with a larger swing over the bed and a more substantial chuck capacity. This allows them to handle heavy-duty components like drill pipes, wellheads, and large flanges.

- Robust Construction: These lathes are built with a sturdier, more rugged frame and components to withstand the demanding conditions of the oilfield, such as high torque, vibration, and heavy loads.

- Increased Power: Oil Country Lathes are equipped with more powerful motors and drive systems to handle the increased cutting forces required for larger workpieces.

- Enhanced Accuracy: The precision engineering and tight tolerances of oil country lathe machine ensure a high degree of accuracy and repeatability, which is crucial for the manufacture and maintenance of critical oilfield components.

- Specialized Accessories: Oil Country Lathes often come with specialized accessories, such as heavy-duty chucks, steady rests, and tailstock assemblies, to handle the unique requirements of oilfield work.

The Standard Lathe Machine

Standard lathe is also known as a bench lathe or a metal lathe and is a more general-purpose machine tool used in a wide range of manufacturing and metalworking applications, including automotive, aerospace and general engineering.

Key Features of the Standard Lathe:

- Smaller Capacity: Standard Lathes are typically smaller and have a more compact design, with a smaller swing over the bed and chuck capacity. This makes them well-suited for smaller workpieces and more precise, detailed work.

- Versatile Design: Standard Lathes are often more versatile, with the ability to perform a wider range of operations, such as threading, knurling, and taper turning, thanks to their more diverse tooling options.

- Easier to Operate: Standard Lathes tend to be more user-friendly, with simpler controls and a smaller footprint, making them a better choice for smaller workshops or hobbyist applications.

- Lower Cost: Due to their more general-purpose design and smaller size, Standard Lathes are often less expensive than their Oil Country counterparts.

Differences in Performance and Applications

The fundamental differences between oil country lathe machine and Standard Lathes stem from their intended applications and the unique demands of their respective industries.

Oil Country Lathes are specifically designed to handle the large, heavy, and often irregular workpieces found in the oil and gas industry. Their robust construction, increased power, and specialized accessories make them well-suited for tasks such as turning, boring, and threading large oilfield components like drill pipes, wellheads, and flanges. These lathes are essential for the manufacture, repair, and maintenance of critical oilfield equipment.

Standard Lathes are more versatile and better suited for a wide range of general metalworking tasks, from small-scale production to prototype development and custom fabrication. Their smaller capacity and more user-friendly design make them a better choice for workshops, hobbyists, and small-to-medium-sized manufacturing operations where precise, detailed work on smaller workpieces is the primary focus.

Choosing the Right Lathe for Your Needs

When selecting a lathe, it's crucial to consider the specific requirements of your application, such as the size and weight of the workpieces, the level of precision required, and the overall production demands. By understanding the key differences between oil country lathe machine and Standard Lathes, you can make an informed decision that will ensure the optimal performance and efficiency of your metalworking operations.

In simpler terms, oil country lathe machine are the muscle machines for the oil and gas industry. They're built big and strong to handle giant metal parts like pipes and wellheads. Standard lathes, on the other hand, are more like all-rounders, good for a variety of regular metalworking jobs. They offer a good mix of power, accuracy, and price. Picking the right lathe depends on what you need it for, whether it's manufacturing, fixing things or working on machines in your workshop machinery.