High-Quality PP Spunbond Nonwoven Fabric for Versatile Applications

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

In the dynamic world of textiles, the need for innovative and versatile materials is ever-growing. One such material that has gained significant traction is PP (Polypropylene) spunbond nonwoven fabric. Singhal Industries, a leading manufacturer of flexible packaging products, is proud to offer high-quality PP spunbond nonwoven fabric that caters to a wide array of applications, ensuring durability, efficiency, and cost-effectiveness.

What is PP Spunbond Nonwoven Fabric?

PP Spunbond Exporter in Ahmedabad is made from polypropylene, a thermoplastic polymer known for its strength and durability. The manufacturing process involves melting the polypropylene granules and extruding them into continuous filaments. These filaments are then laid down in a random manner to form a web, which is bonded together through heat and pressure, creating a strong and cohesive fabric.

Advantages of PP Spunbond Nonwoven Fabric

1. Strength and Durability

One of the standout features of PP spunbond nonwoven fabric is its exceptional strength and durability. The fabric's structure provides high tensile strength, making it resistant to tears and punctures. This durability ensures that products made from this fabric can withstand demanding conditions and repeated use.

2. Lightweight and Breathable

Despite its strength, PP spunbond nonwoven fabric is lightweight, which makes it easy to handle and transport. Additionally, the fabric is breathable, allowing air to pass through while still providing a barrier against dust, particles, and liquids. This breathability is particularly important in applications such as medical and hygiene products.

3. Cost-Effective

PP spunbond nonwoven fabric is a cost-effective material, offering excellent performance at a reasonable price. Its manufacturing process is efficient, and the raw material, polypropylene, is relatively inexpensive. This cost-effectiveness makes it a popular choice for various industries looking to balance quality and budget.

4. Versatility

The versatility of PP spunbond nonwoven fabric is one of its most appealing attributes. It can be used in a wide range of applications, from medical and hygiene products to agriculture, automotive, and construction industries. Its adaptability makes it a go-to material for many different purposes.

5. Eco-Friendly

Singhal Industries is committed to sustainability, and PP spunbond nonwoven fabric aligns with this commitment. The fabric is recyclable, and its production process generates minimal waste. Additionally, its lightweight nature reduces transportation costs and the associated carbon footprint.

Applications of PP Spunbond Nonwoven Fabric

1. Medical and Hygiene Products

In the medical field, PP spunbond nonwoven fabric is used to manufacture surgical gowns, masks, caps, and shoe covers. Its strength and breathability provide an effective barrier against contaminants while ensuring comfort for the wearer. In hygiene products, it is used for making diapers, sanitary napkins, and adult incontinence products, where its softness and absorbency are crucial.

2. Agriculture

PP spunbond nonwoven fabric is widely used in agriculture for applications such as crop covers, weed control fabrics, and greenhouse shading. The fabric helps protect plants from pests, extreme weather conditions, and UV radiation while allowing air and moisture to pass through, promoting healthy plant growth.

3. Automotive Industry

In the automotive industry, PP spunbond nonwoven fabric is used for interior components such as headliners, seat covers, and trunk liners. Its durability, lightweight nature, and sound-absorbing properties make it an ideal material for enhancing vehicle interiors.

4. Construction

In construction, PP spunbond nonwoven fabric is used for applications such as roofing underlayment, insulation, and geotextiles. The fabric's strength and resistance to moisture make it suitable for protecting structures from water damage and providing stability to soil and foundation layers.

5. Packaging

PP spunbond nonwoven fabric is also used in the packaging industry for creating reusable bags, protective covers, and insulation materials. Its durability and cost-effectiveness make it an excellent choice for packaging solutions that require strength and longevity.

Manufacturing Process of PP Spunbond Nonwoven Fabric

The manufacturing process of PP Spunbond non woven fabric manufacturer involves several key steps to ensure the production of high-quality and consistent fabric. Here is an overview of the process:

-

Extrusion: Polypropylene granules are melted and extruded through spinnerets to form continuous filaments. These filaments are cooled and stretched to achieve the desired diameter and strength.

-

Web Formation: The filaments are laid down in a random manner on a moving conveyor belt to form a web. This random arrangement ensures that the fabric has uniform strength and thickness.

-

Bonding: The web is passed through heated rollers or subjected to hot air, which bonds the filaments together. This bonding process gives the fabric its strength and cohesion.

-

Finishing: The bonded fabric is treated with various finishing processes, such as calendering, to improve its surface properties and appearance. Additional treatments, such as hydrophobic or hydrophilic coatings, can be applied to enhance the fabric's performance for specific applications.

-

Quality Control: The finished fabric undergoes rigorous quality control checks to ensure it meets the required standards of strength, durability, and appearance.

Customization Options for PP Spunbond Nonwoven Fabric

At Singhal Industries, we understand that different industries have unique requirements for nonwoven fabrics. That's why we offer a wide range of customization options for our PP spunbond nonwoven fabric. Here are some of the ways you can customize your fabric:

-

Weight and Thickness: Choose from a variety of weights and thicknesses to meet your specific application needs. Whether you need a lightweight fabric for hygiene products or a heavier fabric for construction, we can provide the perfect solution.

-

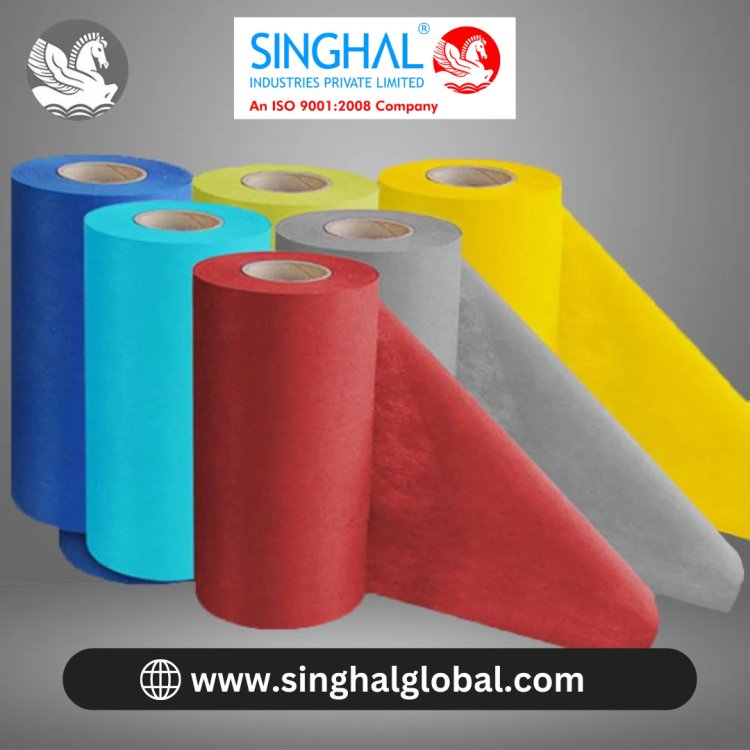

Color: Select from a wide range of colors to match your branding or aesthetic preferences. Our color options ensure that your products stand out and leave a lasting impression.

-

Finishes and Coatings: Enhance the performance of your fabric with specialized finishes and coatings. Options include hydrophobic or hydrophilic treatments, UV resistance, flame retardancy, and anti-static properties.

-

Printing: Customize your fabric with logos, branding, and other information using various printing techniques. This customization adds a professional touch and helps in brand promotion.

Maintenance and Care of PP Spunbond Nonwoven Fabric

Proper maintenance and care can extend the lifespan of your PP spunbond nonwoven fabric, ensuring it remains in good condition for multiple uses. Here are some tips for maintaining and caring for your fabric:

-

Cleaning: Clean the fabric regularly with a damp cloth and mild soap to remove dirt and debris. Avoid using harsh chemicals or abrasive cleaners, as they can damage the material.

-

Storage: Store the fabric in a cool, dry place away from direct sunlight and extreme temperatures. Proper storage prevents degradation of the material and extends the fabric's lifespan.

-

Inspection: Periodically inspect the fabric for signs of wear and tear, such as fraying or weakened areas. Repair any damage promptly to maintain the fabric's integrity and functionality.

Why Choose Singhal Industries for PP Spunbond Nonwoven Fabric?

Singhal Industries is a trusted name in the flexible packaging industry, known for our commitment to quality, innovation, and customer satisfaction. Here are a few reasons to choose our PP spunbond nonwoven fabric:

-

High-Quality Materials: We use premium-grade polypropylene to manufacture our spunbond nonwoven fabric, ensuring it meets the highest standards of strength, durability, and performance.

-

Sustainable Practices: Our manufacturing process is designed to minimize waste and reduce environmental impact. We use recyclable materials and implement eco-friendly practices to create products that are both high-quality and environmentally responsible.

-

Customization Options: We offer a wide range of customization options to meet your specific needs. Our team of experts is here to help you design the perfect fabric for your applications.

-

Competitive Pricing: Our PP spunbond nonwoven fabric is cost-effective, providing excellent value for your investment. We offer competitive pricing without compromising on quality or performance.

-

Customer Support: At Singhal Industries, we prioritize customer satisfaction. Our dedicated customer support team is available to assist you with any questions or concerns, ensuring a smooth and positive experience.

Conclusion

PP spunbond nonwoven fabric from Singhal Industries offers a durable, versatile, and cost-effective solution for a wide range of applications. Whether you are in the medical, agricultural, automotive, construction, or packaging industry, our high-quality fabric provides the performance and reliability you need to succeed.

By choosing our PP Spunbond nonwoven Supplier India, you are investing in a material that delivers exceptional strength, breathability, and eco-friendliness. Our commitment to quality and customer satisfaction ensures that you receive the best products and services in the industry.

Contact Singhal Industries today to learn more about our PP spunbond nonwoven fabric and how we can help meet your specific requirements. Transform your applications with our high-quality, versatile, and cost-effective fabric, and experience the difference in quality and performance.

FAQS

1. What is PP spunbond nonwoven fabric made of?

PP spunbond nonwoven fabric is made from polypropylene, a thermoplastic polymer known for its strength and durability. The fabric is created by extruding and bonding polypropylene fibers together.

2. What are the advantages of PP spunbond nonwoven fabric?

PP spunbond nonwoven fabric offers exceptional strength, durability, lightweight nature, breathability, and cost-effectiveness. It is versatile and can be used in various industries for different applications.

3. In which industries is PP spunbond nonwoven fabric used?

PP spunbond nonwoven fabric finds applications in industries such as medical and hygiene products, agriculture, automotive, construction, and packaging. Its properties make it suitable for a wide range of uses.

4. Can PP spunbond nonwoven fabric be customized?

Yes, PP spunbond nonwoven fabric can be customized in terms of weight, thickness, color, finishes, coatings, and printing. This customization allows it to meet specific requirements for different applications.

5. How should PP spunbond nonwoven fabric be maintained?

PP spunbond nonwoven fabric should be cleaned regularly with mild soap and water, stored in a cool, dry place away from direct sunlight, and inspected for damage. Proper maintenance helps extend its lifespan and effectiveness.