HDPE Sheets Manufacturer in India | High Density Polyethylene- Monoindustries

HDPE sheets manufacturers understand the diverse needs of industries. Offering customization options, they allow clients to choose thickness and dimensions tailored to their specific applications—whether it's thin sheets for flexibility or thicker variants for structural robustness.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

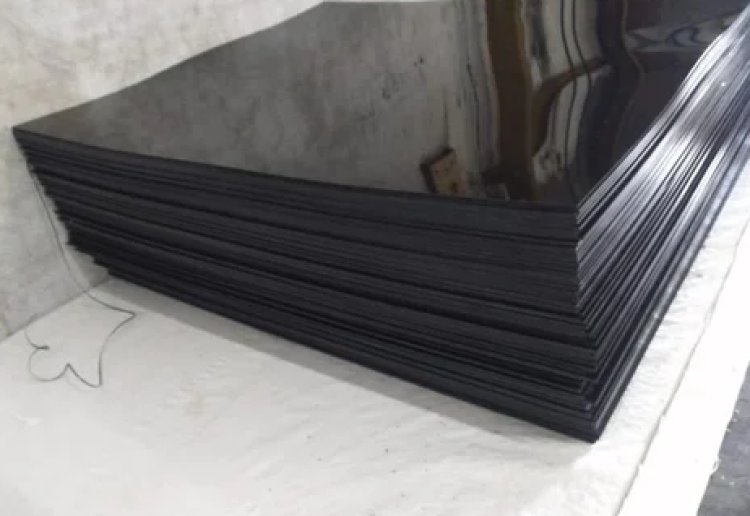

In the realm of industrial materials, High-Density Polyethylene (HDPE) sheets emerge as silent yet indispensable champions. Behind their versatile applications and reliability lies the intricate art and science of HDPE sheets manufacturing. Let's delve into the fascinating world where precision meets polymers, and craftsmanship converges with cutting-edge technology, shaping the very fabric of HDPE sheets.

Harvesting the Raw Essence: The HDPE Polymer Selection

1. Prudent Polymer Choices

At the heart of HDPE sheets manufacturing is the meticulous selection of HDPE polymers. Manufacturers navigate through a plethora of polymer options, choosing with precision to ensure the sheets possess the desired characteristics such as durability, flexibility, and resistance to environmental elements.

2. Enhancing Properties with Additives

Crafting the perfect HDPE sheet involves the thoughtful addition of various additives. UV stabilizers for outdoor endurance, antioxidants for prolonged life, and colorants for aesthetic appeal are artfully incorporated. These additives transform HDPE from a base polymer into a tailored material, ready for diverse applications.

The Extrusion Ballet: Shaping the HDPE Canvas

3. Precision Extrusion Process

The star of the manufacturing process is the extrusion stage. Here, the selected HDPE polymer takes center stage, melting and molding into continuous sheets through a meticulously calibrated die. This dance of precision ensures uniform thickness, an essential characteristic for the reliability of the end product.

4. Cooling Choreography

Post-extrusion, the sheets undergo a carefully choreographed cooling process. This cooling dance, akin to annealing, minimizes internal stresses within the material. The result is HDPE sheets with optimal dimensional stability and resistance to warping—an imperative for their performance in real-world applications.

Customization Palette: Tailoring HDPE Sheets to Perfection

5. Bespoke Thickness and Dimensions

HDPE sheets manufacturers understand the diverse needs of industries. Offering customization options, they allow clients to choose thickness and dimensions tailored to their specific applications—whether it's thin sheets for flexibility or thicker variants for structural robustness.

6. Specialty Formulations for Varied Applications

Crafting HDPE sheets involves the formulation of specialized variants. Whether it's sheets designed for extreme weather conditions, chemical resistance, or compliance with industry standards, manufacturers adeptly formulate materials to meet the unique demands of diverse applications.

Quality Assurance Symphony: Ensuring Excellence in Every Sheet

7. Rigorous Quality Testing

The masterpiece comes to life through rigorous quality testing. HDPE sheets undergo meticulous inspections, ensuring dimensional accuracy, color consistency, and material strength. This commitment to quality guarantees that each sheet meets the stringent standards set by the industry.

8. Seals of Excellence with Certifications

Leading HDPE sheets manufacturers often hold certifications as seals of excellence. ISO standards and other certifications become badges of honor, assuring clients that the manufactured sheets adhere to the highest quality control measures.

Sustainability in Every Fiber: HDPE Sheets and the Environment

9. Embracing the Eco-Friendly Nature of HDPE

In the canvas of HDPE sheets manufacturing, sustainability takes center stage. HDPE, being inherently recyclable, aligns with eco-friendly practices. Manufacturers embrace this aspect, contributing to global efforts for sustainable industrial solutions and a circular economy.

10. Responsible End-of-Life Practices

The commitment to sustainability extends to the end-of-life stage. Manufacturers guide customers on responsible disposal methods, promoting recycling and environmentally conscious practices to ensure that the life cycle of HDPE sheets remains as green as their inception.

Conclusion: Crafting the Future, One Sheet at a Time

In conclusion, HDPE sheets manufacturing is an intricate dance of science and artistry. From polymer selection to extrusion precision, customization to quality assurance, manufacturers craft each sheet with meticulous care. HDPE sheets, versatile and reliable, stand as testaments to the mastery achieved in their manufacturing—a craftsmanship that shapes industries, applications, and the very fabric of our modern world.

![ChakraFlowX Review [FRAUD Or LEGIT 2024] Beware Scam Warning & Fake Side Effects!](https://blog.rackons.in/uploads/images/202408/image_380x226_66d0543749ee5.jpg)