Beyond Soil Stabilization: The Diverse Uses of Polyester Geogrids

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

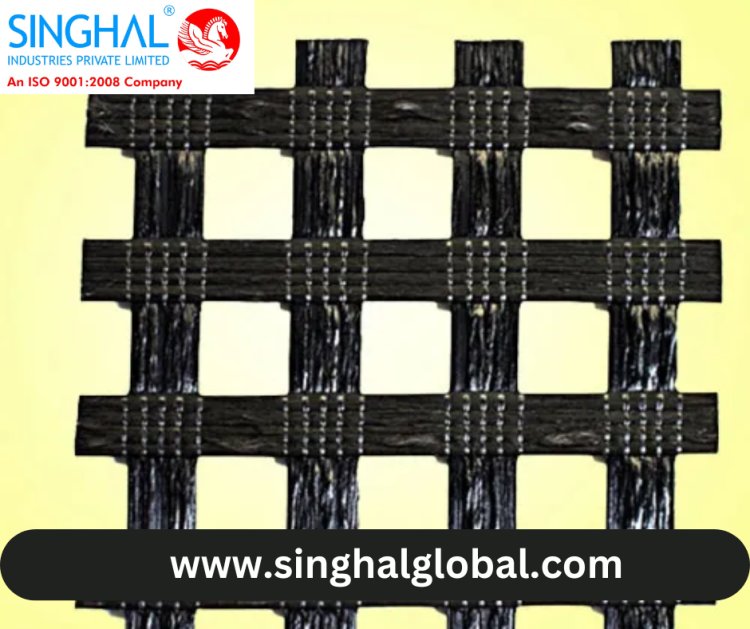

Polyester geogrids are a crucial component in modern civil engineering, offering a range of benefits that extend beyond simple soil stabilization. Singhal Industries, a leading manufacturer of flexible packaging products, has developed advanced polyester geogrids that provide exceptional performance across various applications. This blog will explore the diverse uses and advantages of polyester geogrids, highlighting why they are an indispensable tool in construction and infrastructure projects.

What Are Polyester Geogrids?

Polyester geogrids are synthetic materials made from high-strength Polypropylene geogrid suppliers coated with a protective polymer. They are designed to reinforce soils and other granular materials, enhancing the structural integrity and longevity of various constructions. These geogrids come in different strengths and sizes, tailored to meet specific engineering requirements.

Key Advantages of Polyester Geogrids

- High Tensile Strength: Polyester geogrids offer remarkable tensile strength, making them ideal for reinforcing weak soils and preventing deformation under heavy loads.

- Durability: Resistant to chemical and biological degradation, polyester geogrids maintain their integrity over long periods, even in harsh environmental conditions.

- Flexibility: These geogrids can adapt to various soil conditions and are easy to install, providing versatile solutions for numerous construction challenges.

- Cost-Effective: By enhancing soil strength and stability, polyester geogrids reduce the need for extensive ground preparations and expensive materials, leading to significant cost savings.

- Environmental Benefits: Their use reduces the need for natural aggregate extraction, promoting sustainable construction practices.

Applications of Polyester Geogrids

1. Road Construction

Polyester geogrids are widely used in road construction to reinforce the base and sub-base layers. They distribute loads more evenly, preventing rutting and extending the lifespan of roadways. This reinforcement is particularly beneficial in areas with weak or variable soil conditions.

2. Railway Track Support

In railway construction, polyester geogrids enhance the stability of track beds. They reduce track deformation and maintenance costs by providing additional support to the ballast and sub-ballast layers. This leads to safer and more reliable railway operations.

3. Retaining Walls and Slopes

For retaining walls and slope stabilization, polyester geogrids offer essential reinforcement. They prevent soil erosion and slippage, ensuring the structural integrity of retaining structures. This application is crucial in both urban and rural settings, where land development and landscaping are necessary.

4. Landfills and Waste Management

Polyester geogrids play a vital role in landfill construction. They reinforce the base and cap layers, preventing differential settlement and ensuring the stability of waste containment systems. This helps in maintaining environmental safety and compliance with regulatory standards.

5. Airport Runways and Aprons

The heavy loads and high traffic on airport runways and aprons require robust ground support. Polyester geogrids provide the necessary reinforcement to withstand these conditions, enhancing the durability and performance of airport surfaces.

6. Embankments and Earth Dams

In the construction of embankments and earth dams, polyester geogrids offer significant reinforcement. They help in managing the load distribution and preventing structural failure due to soil movement, ensuring the longevity and safety of these critical infrastructures.

7. Mining and Quarrying

The mining and quarrying industries benefit from the use of polyester geogrids in haul roads and waste containment areas. They improve the load-bearing capacity of roads, reducing maintenance and operational costs. In waste containment, they provide stability and prevent contamination.

Installation and Usage Guidelines

To maximize the benefits of polyester geogrids, proper installation is crucial. Here are some general guidelines:

- Site Preparation: Ensure the site is properly prepared, with a smooth and level surface to lay the geogrid.

- Unrolling the Geogrid: Unroll the geogrid carefully, ensuring it is tensioned and free from wrinkles.

- Overlap Sections: When multiple geogrid sections are required, overlap them according to manufacturer recommendations to ensure continuous reinforcement.

- Secure in Place: Use stakes or pins to secure the geogrid in place, preventing movement during the placement of fill material.

- Backfill: Carefully place and compact the fill material over the geogrid, ensuring even distribution and compaction to achieve the desired reinforcement effect.

Case Studies

Case Study 1: Highway Reinforcement

A major highway project required reinforcement due to poor soil conditions. Singhal Industries supplied high-strength polyester geogrids that were used to stabilize the base layers. The result was a significant improvement in road durability and reduced maintenance costs. The highway now supports heavy traffic without signs of rutting or deformation, demonstrating the effectiveness of polyester geogrids in road construction.

Case Study 2: Landfill Stability

A landfill site faced challenges with differential settlement and liner integrity. The use of Polyester geogrid Manufacturers in the base and cap layers provided the necessary reinforcement, ensuring long-term stability and compliance with environmental regulations. The project highlighted the importance of geogrids in waste management and environmental protection.

Future Trends in Polyester Geogrids

The demand for polyester geogrids is expected to grow, driven by the need for sustainable and cost-effective construction solutions. Advances in manufacturing technology are leading to the development of geogrids with even higher strength and durability. Additionally, research into biodegradable coatings and more environmentally friendly materials is underway, further enhancing the sustainability of polyester geogrids.

Conclusion

Polyester geogrids are a versatile and indispensable tool in modern construction and civil engineering. Their ability to reinforce soils, prevent deformation, and extend the lifespan of various structures makes them invaluable in a wide range of applications. Singhal Industries, with its commitment to quality and innovation, continues to provide top-tier polyester geogrids that meet the evolving needs of the industry.

Whether it's for road construction, railway support, retaining walls, or landfill stabilization, Polyester geogrid india offer reliable and cost-effective solutions. By choosing high-quality geogrids from reputable manufacturers like Singhal Industries, construction professionals can ensure the success and longevity of their projects.

Investing in polyester geogrids is not just about enhancing structural integrity; it's also about promoting sustainable construction practices and reducing environmental impact. As the industry moves forward, the role of polyester geogrids will only become more critical in building a safer, more durable, and more sustainable world.

FAQS

1. What are polyester geogrids?

Polyester geogrids are synthetic reinforcement materials made from high-strength polyester yarns. They are used to stabilize and reinforce soils and other granular materials in various construction applications.

2. What are the primary benefits of using polyester geogrids?

Polyester geogrids offer high tensile strength, durability, resistance to chemical and biological degradation, flexibility, and cost-effectiveness. They enhance the structural integrity and longevity of construction projects.

3. In which applications are polyester geogrids commonly used?

Polyester geogrids are used in road construction, railway track support, retaining walls, slope stabilization, landfill reinforcement, airport runways, embankments, and mining operations.

4. How do polyester geogrids contribute to environmental sustainability?

By reinforcing soils and reducing the need for extensive ground preparations and natural aggregates, polyester geogrids help minimize environmental impact. They are also recyclable and promote sustainable construction practices.

5. Why choose Singhal Industries for polyester geogrids?

Singhal Industries offers high-quality polyester geogrids with a focus on durability and performance. With extensive experience and a commitment to innovation, they provide reliable solutions for diverse construction needs.