Unveiling the Versatile World of PP Sheets: Everything You Need to Know

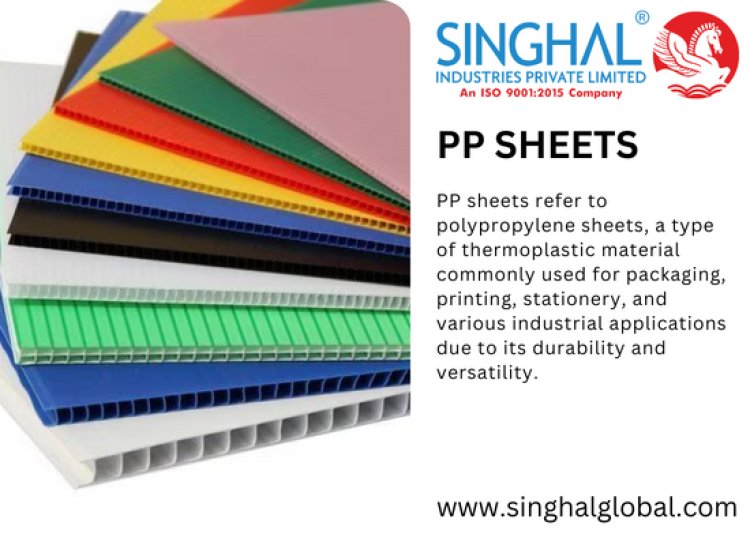

PP sheets, short for polypropylene sheets, are thermoplastic polymer sheets manufactured from polypropylene resin. They are known for their excellent chemical resistance, impact strength, and high melting point, making them suitable for a wide range of applications.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Polypropylene (PP) sheets have become indispensable in various industries due to their versatility, durability, and cost-effectiveness. Whether you're a manufacturer, a designer, or a consumer, understanding Polypropylene Sheets Suppliers can benefit you significantly. In this comprehensive guide, we delve into everything you need to know about PP sheets, from their properties and applications to frequently asked questions.

What are PP Sheets?

PP sheets, short for polypropylene sheets, are thermoplastic polymer sheets manufactured from polypropylene resin. They are known for their excellent chemical resistance, impact strength, and high melting point, making them suitable for a wide range of applications.

Properties of PP Sheets:

Chemical Resistance: Polypropylene Sheets 4x8 are highly resistant to many chemicals, acids, and solvents, making them ideal for applications in industries such as automotive, chemical processing, and healthcare.

Impact Strength: Despite being lightweight, PP sheets offer excellent impact resistance, making them suitable for applications where durability is essential, such as packaging and automotive components.

Heat Resistance: PP sheets have a high melting point, typically ranging from 130°C to 171°C, depending on the grade and additives used. This heat resistance makes them suitable for applications requiring exposure to elevated temperatures.

Flexibility: PP sheets are known for their flexibility and ability to be easily formed into various shapes using techniques like thermoforming and vacuum forming, making them ideal for packaging and signage applications.

Lightweight: PP sheets are lightweight yet sturdy, offering ease of handling and transportation, which is advantageous in applications such as automotive components and construction.

Applications of PP Sheets:

Packaging: Polypropylene Sheet Manufacturers are widely used in packaging applications due to their excellent chemical resistance and flexibility. They are commonly used for food packaging, pharmaceutical packaging, and protective packaging for electronics.

Automotive: PP sheets find extensive use in the automotive industry for manufacturing interior components, exterior trims, and under-the-hood applications due to their lightweight nature and impact resistance.

Construction: PP sheets are used in construction for applications such as wall cladding, roofing, and insulation due to their weather resistance, durability, and ease of installation.

Signage and Displays: PP sheets are popular for indoor and outdoor signage, displays, and point-of-purchase advertising due to their versatility, printability, and weather resistance.

Medical and Healthcare: PP sheets are used in medical and healthcare applications for manufacturing trays, containers, and disposable medical devices due to their sterile nature and chemical resistance.

Conclusion:

PP sheets offer a myriad of benefits across various industries, from packaging and automotive to construction and healthcare. Their unique combination of properties, including chemical resistance, impact strength, and flexibility, makes them a versatile choice for a wide range of applications. By understanding the properties, applications, and frequently asked questions about PP sheets, manufacturers, designers, and consumers can make informed decisions and leverage the advantages offered by this remarkable material.

Frequently Asked Questions (FAQs) About PP Sheets:

Q1: Are PP sheets recyclable?

A1: Yes, PP sheets are recyclable and are commonly recycled to produce new PP products such as containers, automotive parts, and textiles.

Q2: Can PP sheets be used for food packaging?

A2: Yes, PP sheets are FDA-approved for food contact applications, making them suitable for food packaging and containers.

Q3: Are PP sheets UV-resistant?

A3: While PP sheets have some inherent UV resistance, adding UV stabilizers during the manufacturing process can enhance their resistance to UV degradation, making them suitable for outdoor applications.