Unveiling the Benefits of PP Spunbond Nonwoven Fabric: Strength, Versatility, and Eco-Friendliness

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

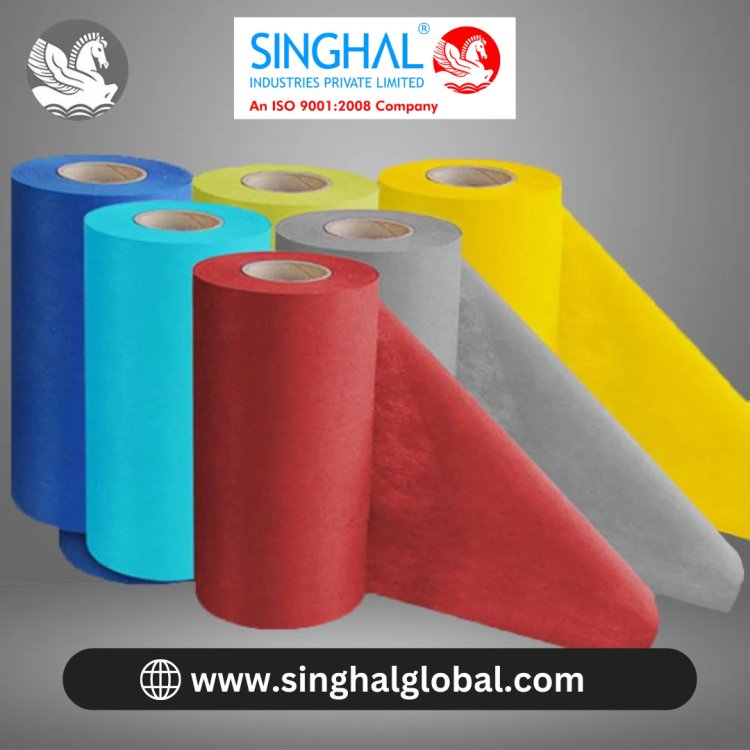

PP spunbond nonwoven fabric has emerged as a versatile and eco-friendly material with a wide range of applications across various industries. Known for its strength, durability, and sustainability, Spunbond nonwoven Supplier India offers unique advantages that make it a preferred choice for many packaging and non-packaging applications. In this comprehensive guide, we will delve into the benefits, uses, manufacturing process, and environmental impact of PP spunbond nonwoven fabric, highlighting why it stands out as a sustainable solution in the realm of flexible packaging and beyond.

Understanding PP Spunbond Nonwoven Fabric

PP spunbond nonwoven fabric is made from polypropylene, a type of thermoplastic polymer known for its excellent properties such as high tensile strength, durability, and resistance to moisture. Unlike traditional woven fabrics, spunbond nonwoven fabric is produced using a continuous filament spinning process. This process involves extruding melted polypropylene granules through spinnerets to form continuous filaments, which are then laid down randomly or in a specific pattern to create a web. The web is then bonded together through heat and pressure, without the need for weaving or knitting.

Key Characteristics of PP Spunbond Nonwoven Fabric

-

Strength and Durability: PP spunbond nonwoven fabric is renowned for its strength and durability, making it suitable for demanding applications where robust performance is required. It can withstand tearing, puncturing, and abrasion, ensuring the integrity of the packaged goods.

-

Versatility: This fabric is highly versatile and can be manufactured in various weights, thicknesses, and widths to meet specific application requirements. It can also be treated to enhance properties such as UV resistance, flame retardancy, and antimicrobial capabilities.

-

Softness and Comfort: Despite its strength, PP spunbond nonwoven fabric is soft to the touch, making it ideal for applications where comfort and aesthetics are important, such as in hygiene products.

-

Breathability: The structure of PP spunbond nonwoven fabric allows air and moisture vapor to pass through, making it suitable for applications requiring breathability, such as medical and hygiene products.

-

Chemical Resistance: It exhibits excellent resistance to chemicals, oils, and solvents, ensuring the protection and safety of the contents.

Applications of PP Spunbond Nonwoven Fabric

PP Spunbond non woven fabric manufacturer finds extensive use in both packaging and non-packaging applications across various industries:

Packaging Applications

-

Shopping Bags: PP spunbond nonwoven fabric is used to manufacture reusable shopping bags due to its durability and eco-friendly nature.

-

Promotional Bags: It is also used for promotional bags and giveaways, where customization with logos and designs is possible.

-

Food Packaging: In food packaging, PP spunbond nonwoven fabric can be used as inner liners or protective layers due to its barrier properties and safety compliance.

Non-Packaging Applications

-

Medical and Hygiene Products: PP spunbond nonwoven fabric is used in surgical gowns, masks, diapers, and sanitary napkins due to its softness, breathability, and fluid resistance.

-

Agriculture: It is employed in agriculture for crop covers, weed control fabrics, and greenhouse shading due to its UV resistance and durability.

-

Filtration: PP spunbond nonwoven fabric is used in air and liquid filtration applications due to its fine fiber structure and high filtration efficiency.

-

Automotive: It finds use in automotive interiors, such as upholstery and carpet backing, for its durability and acoustic insulation properties.

-

Construction: PP spunbond nonwoven fabric is used in geotextiles for erosion control, drainage systems, and reinforcement due to its strength and durability.

Benefits of PP Spunbond Nonwoven Fabric

Eco-Friendliness

PP spunbond nonwoven fabric is considered environmentally friendly for several reasons:

-

Recyclability: It can be recycled and reused in various applications, reducing waste and conserving resources.

-

Energy Efficiency: The manufacturing process of PP spunbond nonwoven fabric consumes less energy compared to traditional textile manufacturing processes.

-

Reduced Carbon Footprint: Its lightweight nature reduces transportation costs and associated carbon emissions.

Sustainability

-

Longevity: PP spunbond nonwoven fabric's durability and resistance to degradation ensure a longer lifespan, reducing the frequency of replacement.

-

Resource Efficiency: It requires fewer raw materials compared to traditional woven fabrics, contributing to resource conservation.

Manufacturing Process of PP Spunbond Nonwoven Fabric

The production of PP spunbond nonwoven fabric involves several key steps:

-

Extrusion: Polypropylene granules are melted and extruded through spinnerets to form continuous filaments.

-

Web Formation: The filaments are laid down randomly or in a specific pattern onto a moving conveyor belt or drum.

-

Bonding: The web of filaments is bonded together using heat and pressure. This bonding process can be thermal bonding, chemical bonding, or mechanical bonding, depending on the desired properties of the fabric.

-

Finishing: The finished fabric may undergo additional treatments such as calendaring (smoothing and compacting), printing, laminating (adding a barrier layer), or embossing (creating patterns or textures).

Conclusion

PP spunbond nonwoven fabric represents a significant advancement in the field of flexible packaging and non-packaging applications. Its strength, versatility, and eco-friendly properties make it a preferred choice for industries looking for sustainable packaging solutions. As a leading manufacturer of flexible packaging products, Singhal Industries is committed to producing high-quality PP spunbond nonwoven fabric that meets the diverse needs of our customers. By choosing Spunbond Exporter in Ahmedabad, businesses can benefit from enhanced product protection, sustainability, and cost-efficiency, contributing to a greener and more sustainable future.

FAQS

1. What is PP spunbond nonwoven fabric made of?

PP spunbond nonwoven fabric is made from polypropylene, a thermoplastic polymer known for its strength and durability. It is produced by extruding melted polypropylene granules into continuous filaments, which are then bonded together to form a fabric without the need for weaving.

2. What are the key benefits of PP spunbond nonwoven fabric?

PP spunbond nonwoven fabric offers several benefits, including high strength, durability, breathability, chemical resistance, and softness. It is versatile and can be used in various applications ranging from packaging to medical and automotive industries.

3. How is PP spunbond nonwoven fabric eco-friendly?

PP spunbond nonwoven fabric is eco-friendly because it is recyclable and reusable. Its production process consumes less energy compared to traditional textile manufacturing, and it can be recycled into new products, reducing environmental impact.

4. In which industries is PP spunbond nonwoven fabric commonly used?

PP spunbond nonwoven fabric finds extensive use in packaging, agriculture, medical and hygiene products, automotive, construction, and filtration industries. Its versatility and durability make it suitable for a wide range of applications.

5. Can PP spunbond nonwoven fabric be customized?

Yes, PP spunbond nonwoven fabric can be customized in terms of weight, thickness, color, and additional treatments such as printing and lamination. This flexibility allows businesses to tailor the fabric to meet specific application requirements and branding needs.