Understanding HDPE T-Rib Liner Sheets: A Comprehensive Guide for Enhanced Infrastructure Protection

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

HDPE T-Rib Liner Sheets have become an essential material in industries that demand long-lasting protection against corrosion, chemicals, and water infiltration. From construction projects to wastewater treatment plants, these innovative sheets provide a robust defense, particularly for concrete structures, ensuring their durability and longevity in challenging environments.

In this article, we will delve into the basics of Mahira Polyglobal LLP, explore their benefits, applications, and answer frequently asked questions to give you a clear understanding of why they are crucial for various industries.

What Are HDPE T-Rib Liner Sheets?

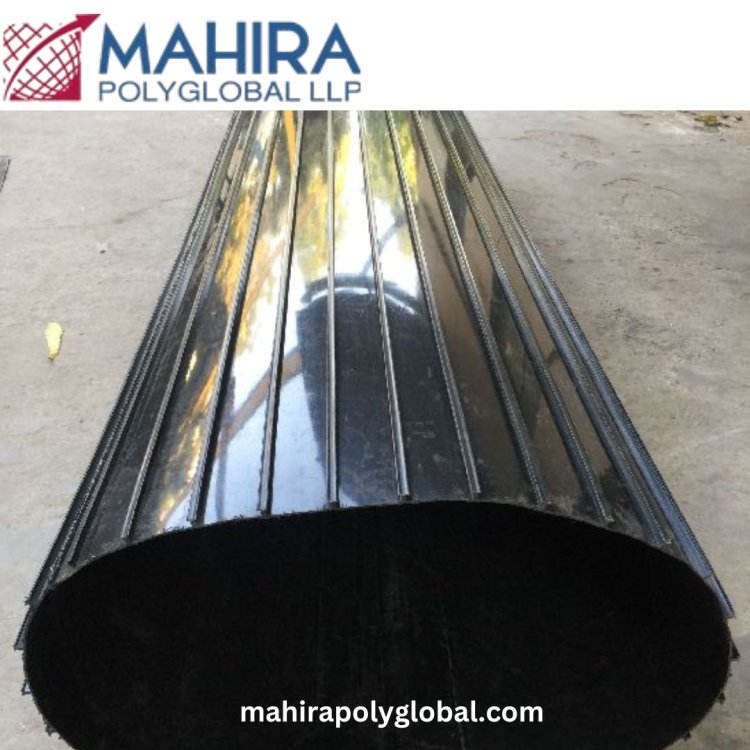

The HDPE T-Rib Sheet Suppliers are high-density polyethylene (HDPE) liners that feature a distinctive T-shaped ribbed structure on one side. These ribs act as anchors, ensuring that the liner stays securely attached to concrete surfaces. This robust design helps protect the surfaces from chemical attack, abrasion, and environmental degradation.

HDPE itself is a versatile, durable, and flexible thermoplastic polymer widely known for its resistance to impact, wear, and various chemicals. The T-Rib addition strengthens its performance by enhancing its grip on the surface, preventing separation, and ensuring long-lasting protection.

Why Use HDPE T-Rib Liner Sheets?

Using HDPE T-Rib Liner Sheets comes with several advantages, making them ideal for a wide array of industrial and infrastructure applications. Let’s explore some of these benefits:

1. Excellent Chemical Resistance

HDPE is inherently resistant to a variety of aggressive chemicals, including acids, alkalis, and solvents. This characteristic makes HDPE T-Rib Liner Sheets perfect for environments where chemical exposure is common, such as wastewater treatment plants, chemical storage facilities, and industrial processing units. These liners act as a barrier, protecting concrete structures from degradation caused by chemical reactions.

2. Waterproofing and Moisture Resistance

HDPE T-Rib Liner Sheets create an impermeable barrier that effectively prevents water infiltration. This quality is crucial for applications where protecting concrete from moisture is necessary, such as in underground tunnels, dams, and reservoirs. With HDPE T-Rib liners in place, the concrete remains shielded from water-related issues like cracking, erosion, or deterioration.

3. Strong Anchorage and Secure Bonding

The T-shaped ribs on the liner provide excellent anchorage to concrete surfaces. These ribs interlock with the concrete, ensuring a strong and secure bond. This reduces the risk of delamination or the liner coming loose over time, making HDPE T-Rib Liner Sheets more reliable than smooth-surfaced liners.

4. Durability and Long Service Life

HDPE T-Rib Liner Sheets are designed to withstand the most challenging environments. They exhibit high resistance to wear and tear, ensuring longevity even in high-traffic areas or where heavy machinery operates. They also provide protection against UV exposure, making them suitable for outdoor applications.

5. Cost-Effective Solution

Given their long service life and minimal maintenance requirements, HDPE T-Rib Liner Sheets are a cost-effective solution. While the initial investment may be higher than other materials, the durability and reduced need for frequent repairs or replacements make them a more economical choice over time.

6. Enhanced Flexibility

Despite their toughness, HDPE T-Rib Liner Sheets are flexible and adaptable. They can be molded to fit complex shapes, making them ideal for structures with curves or irregular surfaces. This adaptability allows for use in a wide range of applications, from storage tanks to tunnels.

7. Environmentally Friendly

HDPE is a recyclable material, and its long-lasting nature reduces the need for frequent replacements, resulting in less waste over time. Additionally, by preserving the integrity of structures and minimizing the need for repair, HDPE T-Rib Liner Sheets contribute to reducing environmental impact.

Applications of HDPE T-Rib Liner Sheets

T-Rib HDPE Liner Sheets India are versatile and can be used in numerous industrial, commercial, and infrastructural projects. Some of the most common applications include:

1. Wastewater Treatment Plants

In wastewater treatment plants, structures are constantly exposed to corrosive chemicals, biological waste, and abrasive materials. HDPE T-Rib Liner Sheets provide a protective layer that shields concrete tanks and pipes from chemical attack and corrosion, thus extending the life of the facility.

2. Mining and Mineral Processing

The mining industry deals with harsh chemicals and abrasive materials that can quickly erode surfaces and equipment. HDPE T-Rib liners are commonly used in processing tanks, sumps, and containment areas to protect against the wear and tear caused by these materials. Their chemical resistance ensures that they remain effective even in the most demanding environments.

3. Tunnels and Underground Infrastructure

Underground structures such as tunnels are prone to water seepage, chemical exposure, and mechanical stress. HDPE T-Rib Liner Sheets act as an effective waterproofing solution, preventing water infiltration and protecting against chemical attack. Their flexibility makes them suitable for curved and irregular surfaces often found in tunnels.

4. Water Storage Tanks and Reservoirs

For large water storage systems, whether for industrial or agricultural use, HDPE T-Rib liners provide an excellent waterproof barrier. Their durability and UV resistance ensure they can withstand long-term exposure to water and weather conditions, keeping the integrity of the storage system intact.

5. Chemical Storage Tanks

In facilities that handle and store chemicals, it is critical to ensure that containment structures remain intact and resistant to leaks. HDPE T-Rib Liner Sheets provide the necessary chemical resistance to prevent degradation of the storage tanks and help avoid costly repairs or environmental contamination.

6. Sewage Systems

Sewage systems are subjected to constant exposure to corrosive elements and biological waste, making them highly vulnerable to wear. HDPE T-Rib Liner Sheets offer protection by preventing corrosion and extending the life of concrete structures such as manholes, pipes, and containment areas.

Installation Process of HDPE T-Rib Liner Sheets

Installing HDPE T-Rib Liner Sheets is a detailed process that requires precision and expertise. Here’s an outline of the typical installation process:

-

Surface Preparation

The surface where the HDPE T-Rib Liner Sheets will be applied needs to be thoroughly cleaned and prepared. Dust, dirt, oil, or any contaminants must be removed to ensure a secure bond between the liner and the surface. -

Positioning the Liner

The T-Rib liner is positioned onto the concrete surface with the ribbed side facing outward. Proper alignment is essential to ensure the ribs can grip the surface securely. -

Seaming and Welding

To create a continuous and impermeable barrier, the seams between sheets are welded together using hot air or extrusion welding techniques. This ensures that no water or chemicals can seep through the joints, enhancing the protective capabilities of the liner. -

Final Inspection

After installation, a thorough inspection is conducted to check for any defects, weak points, or gaps in the liner. This step ensures that the liner will perform optimally and provide long-lasting protection.

Conclusion

HDPE T-Rib Liner Sheets offer an innovative, durable, and effective solution for protecting concrete structures in various industrial and environmental applications. Their resistance to chemicals, water, and mechanical stress, combined with their flexibility and ease of installation, makes them a highly valued material in sectors that demand robust infrastructure protection.

Whether you're involved in wastewater management, mining, or the construction of tunnels and reservoirs, T-Rib HDPE Liner Sheets provide a long-lasting, cost-effective way to safeguard your projects.

Frequently Asked Questions (FAQs)

1. What are HDPE T-Rib Liner Sheets made of?

HDPE T-Rib Liner Sheets are made from high-density polyethylene, a durable plastic material known for its chemical resistance, flexibility, and strength. The T-ribbed design provides enhanced bonding with concrete surfaces.

2. What industries use HDPE T-Rib Liner Sheets?

HDPE T-Rib Liner Sheets are widely used in wastewater treatment plants, mining operations, chemical storage facilities, tunnels, sewage systems, and water storage tanks, among others.

3. How long do HDPE T-Rib Liner Sheets last?

These liners are designed for long-term durability and can last for several decades, depending on the conditions in which they are used. Their resistance to chemicals, UV exposure, and mechanical wear ensures they provide long-lasting protection.

4. Can HDPE T-Rib Liner Sheets be used outdoors?

Yes, HDPE T-Rib Liner Sheets are UV-resistant, making them suitable for outdoor applications like dams, reservoirs, and spillways. They can withstand exposure to sunlight and harsh weather conditions without degrading.