The Unseen Force: Polyester Geogrids - Ground Reinforcement Powerhouse

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

In the realm of modern infrastructure and construction, the unseen elements often play the most critical roles. One such unsung hero is the polyester geogrid. These robust, yet flexible materials have revolutionized the way we approach ground reinforcement, ensuring stability, durability, and efficiency in various applications. At Singhal Industries, we pride ourselves on being at the forefront of manufacturing these innovative solutions. This blog will delve into the importance, applications, and advantages of polyester geogrids, demonstrating why they are indispensable in today's construction landscape.

Understanding Polyester Geogrids

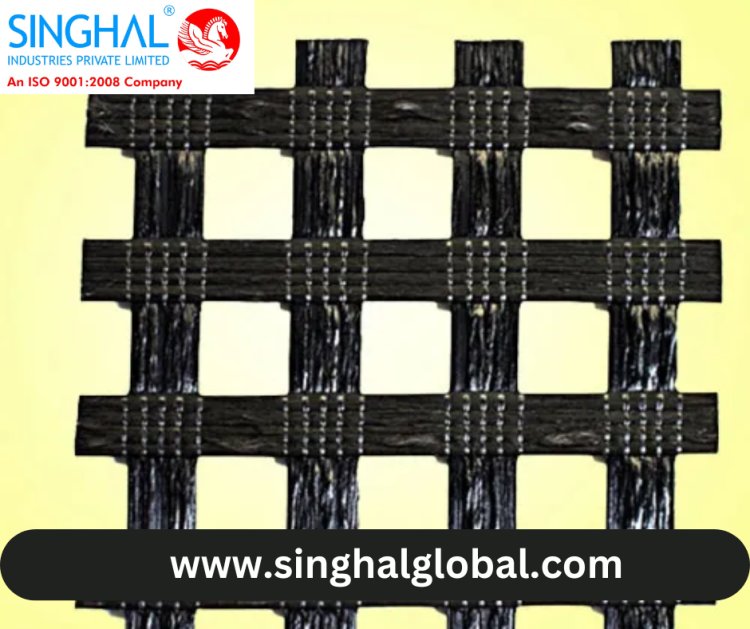

Polypropylene geogrid suppliers are synthetic, high-strength, and highly durable grid structures made from polyester yarns. These grids are coated with a protective layer to enhance their durability and resistance to environmental factors. The primary function of polyester geogrids is to reinforce soils and other granular materials, providing a stable foundation for construction projects.

The Manufacturing Process

The manufacturing of polyester geogrids involves several key steps:

-

Yarn Selection and Preparation: High-quality polyester yarns are selected for their strength and durability. These yarns are then treated to enhance their resistance to UV rays and chemical degradation.

-

Weaving: The treated yarns are woven into a grid pattern. This process involves precise control to ensure the grid's uniformity and strength.

-

Coating: The woven grids are coated with a polymer layer. This coating provides additional protection against environmental factors, such as moisture and chemicals, further enhancing the geogrid's longevity.

-

Quality Control: Each batch of geogrids undergoes rigorous testing to ensure it meets the required standards for strength, flexibility, and durability.

Key Applications of Polyester Geogrids

Polyester geogrids are versatile and find applications in various sectors, including:

-

Road Construction: One of the primary uses of polyester geogrids is in road construction. These grids are placed beneath roadways to distribute loads evenly, reduce rutting, and extend the lifespan of the road surface.

-

Railway Ballast Stabilization: In railway construction, polyester geogrids are used to stabilize the ballast layer, preventing the movement of tracks and enhancing the overall stability of the railway.

-

Retaining Walls and Embankments: Polyester geogrids provide essential support for retaining walls and embankments, ensuring these structures can withstand significant loads and environmental pressures.

-

Soil Reinforcement: These geogrids are employed in various soil reinforcement applications, including slope stabilization, erosion control, and foundation reinforcement.

-

Landfills and Waste Containment: Polyester geogrids play a crucial role in the construction of landfills and waste containment systems, providing structural integrity and preventing subsidence.

Advantages of Polyester Geogrids

The use of polyester geogrids offers several benefits, making them a preferred choice in construction and infrastructure projects:

-

High Strength and Durability: Polyester geogrids are known for their exceptional tensile strength and durability, ensuring long-term performance even in demanding conditions.

-

Cost-Effective: By providing enhanced load distribution and reducing the need for extensive ground preparation, polyester geogrids can significantly lower construction costs.

-

Environmental Resistance: These geogrids are resistant to UV rays, chemicals, and biological degradation, making them suitable for various environmental conditions.

-

Ease of Installation: Polyester geogrids are lightweight and easy to handle, simplifying the installation process and reducing labor costs.

-

Improved Safety: By enhancing the stability of structures, polyester geogrids contribute to the safety of construction projects, reducing the risk of structural failures.

Singhal Industries: Leading the Way in Polyester Geogrid Manufacturing

At Singhal Industries, we are committed to delivering high-quality polyester geogrids that meet the diverse needs of our clients. Our state-of-the-art manufacturing facilities, combined with stringent quality control measures, ensure that our geogrids are of the highest standard.

We understand the critical role that geogrids play in construction and infrastructure projects, and we continuously invest in research and development to enhance our product offerings. Our team of experts works closely with clients to provide customized solutions that meet their specific requirements, ensuring optimal performance and satisfaction.

Case Studies: Real-World Applications of Polyester Geogrids

Case Study 1: Roadway Reinforcement in Harsh Climates

In a project located in a region with extreme weather conditions, Singhal Industries provided polyester geogrids to reinforce a newly constructed roadway. The geogrids effectively distributed the loads, reducing the formation of ruts and potholes. As a result, the roadway's lifespan was significantly extended, and maintenance costs were reduced.

Case Study 2: Slope Stabilization for a Residential Development

A residential development project faced challenges with slope stability. Singhal Industries supplied Polyester geogrid Manufacturers to reinforce the slopes, preventing erosion and ensuring the safety of the homes built on the hillside. The geogrids provided a cost-effective and durable solution, safeguarding the investment in the development.

The Future of Polyester Geogrids

As construction and infrastructure demands continue to grow, the importance of durable and reliable reinforcement solutions like polyester geogrids will only increase. Advancements in materials science and manufacturing technologies will further enhance the performance and versatility of geogrids, opening up new possibilities for their application.

At Singhal Industries, we are excited about the future of polyester geogrids and remain committed to leading the way in innovation and quality. Our ongoing research and development efforts aim to push the boundaries of what geogrids can achieve, ensuring that our clients always have access to the best reinforcement solutions available.

Conclusion

Polyester geogrid india are a testament to the power of innovation in construction and infrastructure. These unassuming materials provide the unseen force behind stable, durable, and cost-effective projects, ensuring the safety and longevity of the structures they support. At Singhal Industries, we are proud to be at the forefront of this technological advancement, delivering high-quality geogrids that meet the diverse needs of our clients.

Whether you are working on a roadway, railway, retaining wall, or any other construction project, consider the unparalleled benefits of polyester geogrids. Trust Singhal Industries to provide the reliable, high-performance solutions you need to build with confidence and ensure the success of your projects.

FAQS

What are polyester geogrids?

Polyester geogrids are synthetic materials made from high-tenacity polyester yarns that are knitted or woven together to form a grid-like structure. They are used primarily to reinforce soil, offering strength and stability to various civil engineering projects.

How do polyester geogrids reinforce the ground?

Polyester geogrids reinforce the ground by distributing loads over a wider area, increasing soil stability, and reducing settlement. They are placed within the soil layers to improve tensile strength and prevent deformation under stress.

What are the main applications of polyester geogrids?

Polyester geogrids find applications in road construction, railway embankments, retaining walls, landfill slopes, and other infrastructure projects where soil stabilization and reinforcement are crucial. They are also used in residential and industrial construction for strengthening foundations.

What are the advantages of using polyester geogrids?

Some advantages include high tensile strength, chemical resistance, durability, and ease of installation. They can accommodate differential settlements and offer long-term performance in various environmental conditions.

How are polyester geogrids different from other geosynthetic materials?

Polyester geogrids differ from other geosynthetic materials like geotextiles due to their structural reinforcement capabilities. Geotextiles primarily act as filters or separators, whereas geogrids provide mechanical stabilization through their grid-like structure and tensile strength properties.