The Intricate Process of Making Macaroni in a Factory

In this article, we'll delve into the fascinating journey of how macaroni is made in a factory, highlighting the integral role of the innovative Macaroni Making Machine.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

With its comforting and versatile nature, Macaroni has been a beloved staple in cuisines worldwide for centuries. While making it at home is a delightful endeavor for many, the mass production of macaroni involves a meticulous process within a factory setting. In this article, we'll delve into the fascinating journey of how macaroni is made in a factory, highlighting the integral role of the innovative Macaroni Making Machine.

1. Ingredient Preparation:

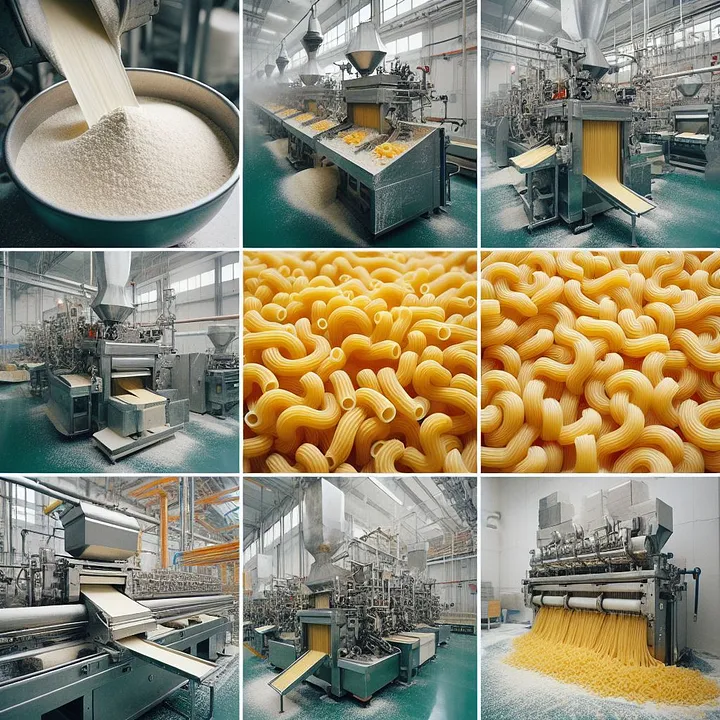

The journey of macaroni begins with the selection of high-quality durum wheat semolina flour, water, and sometimes eggs. These ingredients are precisely measured and mixed to form a dough with the perfect consistency. The dough undergoes rigorous quality checks to ensure it meets the desired standards for texture and taste.

2. Extrusion Process:

Here's where the magic of the Macaroni Making Machine comes into play. The dough is fed into the extruder, a crucial component of the machine. This extruder features various dies and molds that shape the dough into the desired macaroni shapes, such as elbows, shells, or twists. The pressure and temperature within the extruder are carefully regulated to achieve uniformity in shape and size.

Once the macaroni shapes are formed, they enter the drying phase. In a controlled environment, the freshly extruded macaroni is transported through a series of drying chambers. Here, hot air circulates around the pasta, gradually removing moisture and solidifying its structure. This step is crucial for enhancing shelf life and preventing spoilage.

4. Quality Assurance:

Throughout the entire manufacturing process, stringent quality control measures are implemented. Skilled technicians continuously monitor the macaroni for any irregularities in shape, size, or texture. Any deviations from the standards are promptly addressed to maintain the integrity and consistency of the final product.

5. Packaging and Distribution:

Once the macaroni has undergone thorough inspection and meets the quality criteria, it is ready for packaging. Automated packaging lines carefully weigh and fill the macaroni into various packaging formats, ranging from bags to boxes. Each package is labeled with essential information, including nutritional details and expiration dates. Finally, the packaged macaroni is prepared for distribution to retailers and consumers worldwide.

6. Maintenance and Optimization:

Behind the scenes, a dedicated team of engineers and technicians ensures the smooth operation of the Macaroni Making Machine. Regular maintenance checks are conducted to prevent breakdowns and optimize efficiency. Additionally, ongoing research and development efforts strive to enhance the machine's capabilities, leading to continuous improvements in macaroni production.

The process of making macaroni in a factory is a testament to precision engineering and meticulous craftsmanship. From the careful selection of ingredients to the innovative technology of the Macaroni Making Machine, every step is geared towards delivering a high-quality product that delights consumers around the globe. So, the next time you enjoy a plate of perfectly cooked macaroni, take a moment to appreciate the intricate journey it undertook from factory to fork.

growmaxinternational1

growmaxinternational1