The Future of Sheet Metal Rolling: Innovations and Trends

Discover the latest innovations and trends shaping the future of sheet metal rolling for enhanced precision and efficiency.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

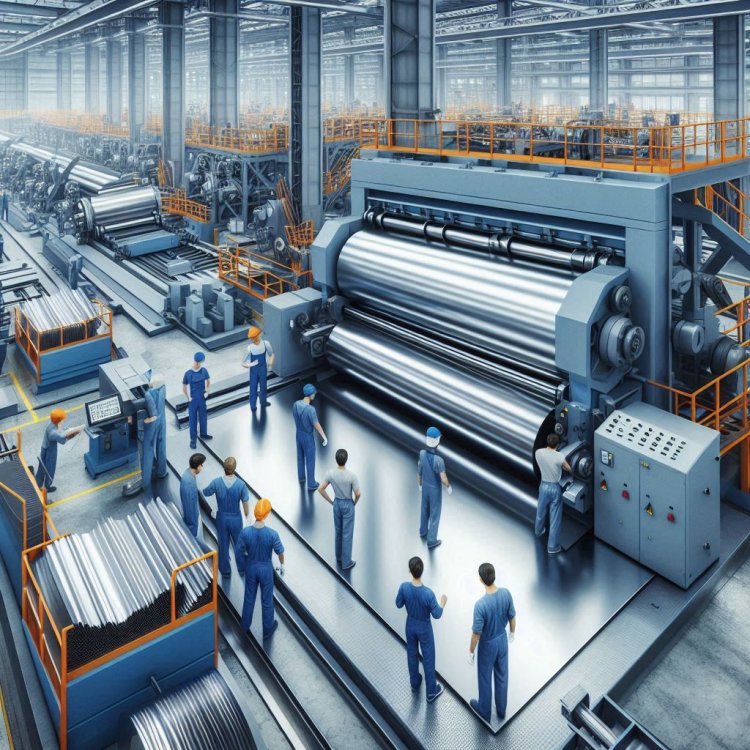

Progressive innovations and trends are being set for the future of sheet metal rolling in the quest for efficiencies, precision, and sustainability. Due to improvements made in CNC technology, automation, and AI-powered control systems, the present-day sheet metal rollers are creating incredible levels of accuracy and consistency in metal forming processes. The addition of IoT-enabled monitoring systems has further allowed Sheet metal roller manufacturer to monitor their machine performance in real time, helping them reduce machine downtime and increase productivity. The trending shift in favor of environmentally friendly manufacturing has developed energy-efficient rollers that optimize resource consumption and waste during production processes. With the fast turnaround high-quality component needs from the industries, evolution of metal sheet rolling will answer those challenges.

Choosing the Right Type of Sheet Metal Roller for Your Business

Always taking into account the efficiency, accuracy, or cost-efficiency that effectively describes the requires of their business, his owners should consider a number of factors before choosing their roller for sheet metal fabrication. They start from the basis of evaluating the type of material and thickness they will be rolling; rollers fall under various designs due to their strength and flexibility. Besides considering getting one that has enough rolling width and diameter capacity for what will suit their particular production requirements, the owner will have to look into the machine capacity related to the work. The more definite features of sheets such as manual, hydraulic, and CNC -controlled rollers-all respond differently to your operations depending on their scale and complexity. Simple additional considerations would be the presence of pre-bending capabilities, automation options, or safety interlocks for more productivity and worker protection. A correctly configured high-quality sheet metal rolling machine will enhance product quality and minimize operational costs over the long haul.

Precision and Efficiency: The Advantages of Modern Sheet Metal Rollers

New developments sheet metal rollers are the precision and efficiency equipment that changes the game across various fields for working metals. Such advancements in the machines promise proper bends and rolls suitable to the needs of end users, highly reducing material wastage and reworking. Elements of CNC technology and automation, by control of the systems in the hydraulic and servo-driven systems, provide easy transportation of the material during processing in a smooth and defect-free finish, even with complex shapes, due to the fact that pressure is consistently distributed. Programmable settings and real-time monitoring are among the other advanced features that improve workflow performance by reducing human labor and machine idleness. Speed, accuracy, and reliability are the best-substantiated benefits that result from using modern roller sheet metal. Hence, these will help you raise the quality of output and make your cost optimize, thus essential in competitive and high-demand cost environments.