The Essential Guide to Servo Motors in Singapore

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Servo motors are pivotal in various industries, providing precise control over motion and positioning. In Singapore, where technological advancements are rapidly integrated into industries, understanding servo motors is essential for engineers, hobbyists, and businesses alike. This guide aims to demystify servo motors, offering detailed insights into their workings, types, applications, and the future of this technology.

Servo motors have been around for decades, but their evolution has been significant, especially with the advent of digital technology. Initially used in simple applications, they are now integral to complex systems in robotics, manufacturing, and even everyday appliances. Their ability to offer accurate control makes them indispensable in sectors where precision is paramount.

Introduction to Servo Motors

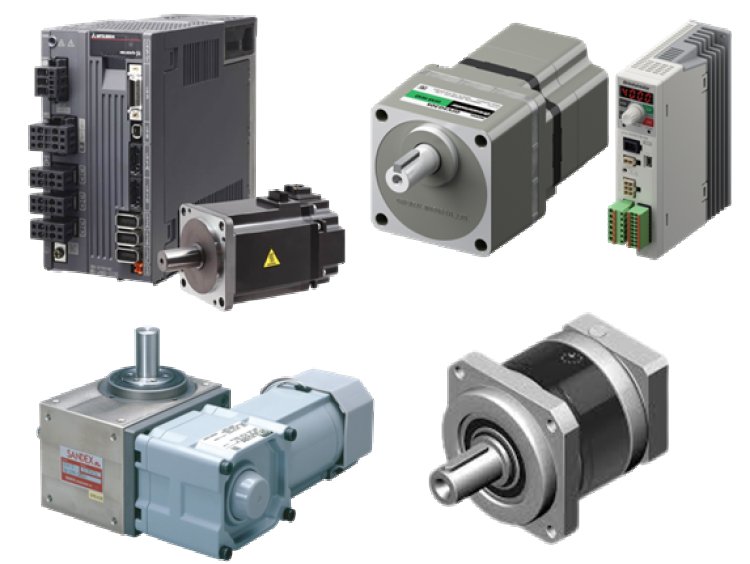

Servo motors are essential components in modern engineering and automation systems. They are designed to provide precise control of angular or linear position, velocity, and acceleration. A typical servo motor system comprises a motor, a feedback device, a controller, and a drive.

What is a Servo Motor?

A servo motor is a rotary or linear actuator that allows for precise control of angular or linear position, speed, and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. The term "servo" refers to the feedback loop that controls the motor's operation.

Basic Operation Principles

Servo motors operate on the principle of feedback control. A control signal, usually in the form of a pulse width modulation (PWM) signal, dictates the motor's movement. The feedback device, typically an encoder or resolver, provides real-time data on the motor's position, allowing the controller to adjust accordingly.

Key Components of a Servo Motor System

- Motor: The main component that converts electrical energy into mechanical motion.

- Controller: Processes the input signal and sends the necessary commands to the motor.

- Feedback Device: Provides real-time information on the motor's position or speed.

- Drive: Converts the controller's commands into electrical signals that the motor can understand.

Types of Servo Motors

Servo motors can be classified into various types based on their operation and design:

- AC Servo Motors: These use alternating current and are known for their high efficiency and performance in demanding applications.

- DC Servo Motors: Operate on direct current and are typically used in simpler applications due to their ease of control.

- Brushless Servo Motors: Known for their longevity and low maintenance due to the absence of brushes.

- Brushed Servo Motors: Feature brushes and commutators and are often used in cost-sensitive applications.

Advantages of Servo Motors

- Precision: High accuracy in controlling position and speed.

- Efficiency: Superior performance in terms of energy consumption.

- Versatility: Suitable for a wide range of applications.

- Reliability: Robust design ensures long-term operation with minimal maintenance.

Applications of Servo Motors

Servo motors are used in various applications, including:

- Industrial Automation: For controlling machinery and processes.

- Robotics: Providing precise movement and positioning of robotic arms.

- CNC Machinery: Ensuring accurate cutting and shaping of materials.

- Aerospace: Used in flight control systems.

- Consumer Electronics: Found in devices like cameras and DVD players.

The Importance of Servo Motors in Singapore

In Singapore, servo motors are crucial in driving the nation's advanced manufacturing and automation sectors. With a strong emphasis on Industry 4.0, the adoption of servo motors is set to increase, supporting the development of smart factories and high-tech industries.

This introductory chapter sets the stage for a deeper exploration of servo motors. The following chapters will delve into the evolution of these motors, their key components, and how they work, providing a comprehensive understanding of this essential technology.

The Evolution of Servo Motors

Servo motors have a rich history, evolving from basic mechanical systems to sophisticated digital devices. Understanding this evolution helps appreciate the technological advancements that have made modern servo motors so powerful and efficient.

Early Beginnings

The concept of feedback control systems dates back to ancient times, with early examples found in Greek and Roman engineering. However, the first true servo mechanisms emerged in the early 20th century, driven by the needs of military and aerospace applications.

World War II and Technological Advancements

During World War II, the demand for precise control systems in military technology spurred significant advancements in servo mechanisms. Early servo systems were used in radar and gun control systems, leading to innovations in feedback control and motor design.

The Rise of Digital Control

The advent of digital technology in the 1970s and 1980s revolutionized servo motors. Microprocessors and digital controllers allowed for more precise and flexible control, leading to the development of AC and brushless servo motors.

Modern Servo Motors

Today, servo motors are integral to a wide range of applications, from industrial automation to robotics and aerospace. Modern servo motors are characterized by their high efficiency, precision, and reliability, thanks to advancements in materials, design, and digital control systems.

Innovations by Hikari Automation

Hikari Automation has been at the forefront of servo motor innovation in Singapore. Their cutting-edge designs incorporate the latest technologies, ensuring superior performance and reliability. Hikari's commitment to quality and innovation has made them a leader in the servo motor industry.

The Future of Servo Motors

The future of servo motors is bright, with ongoing advancements in digital technology, materials science, and manufacturing techniques. The integration of artificial intelligence and machine learning into servo systems promises even greater levels of precision and efficiency.

In the next chapter, we will explore the key components of servo motors, delving into the intricacies of their design and operation. Understanding these components is essential for selecting and maintaining the right servo motor for your application.