Metal 3D Printing Market Expands with Titanium Segment at a robust CAGR

The increasing global Metal 3D Printing market is driven by growing demand for complex and lightweight components, advancements in metal powder development during the forecast period 2024-2028.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

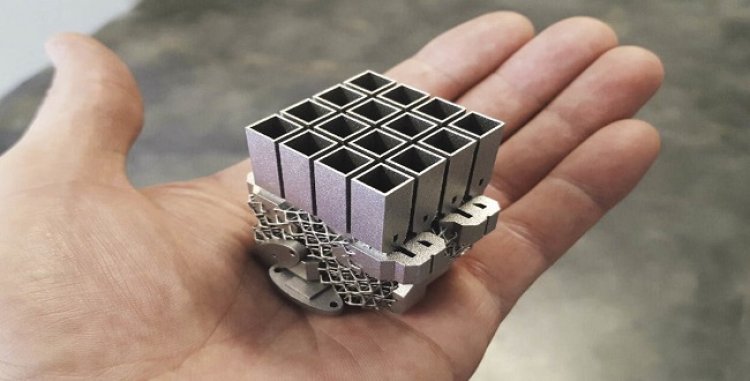

According to TechSci Research report, “Global Metal 3D Printing Market - Global Industry Size, Share, Trends, Opportunity, and Forecast 2018-2028, The Global Metal 3D Printing market has emerged as a transformative force in the world of manufacturing. It represents a shift from traditional subtractive manufacturing to additive manufacturing, where metal components are created layer by layer. This innovative approach has unlocked new possibilities, allowing for the production of complex and highly customized metal parts with unparalleled precision.

Metal 3D Printing finds applications across a wide range of industries. In aerospace, it has revolutionized the production of lightweight and intricately designed aircraft components, reducing weight and fuel consumption. The automotive sector benefits from rapid prototyping, enabling faster product development cycles and customization. Healthcare leverages Metal 3D Printing for the creation of patient-specific implants and medical devices. Furthermore, it has applications in the energy sector, where it aids in the production of complex components for renewable energy systems.

Continuous innovation in materials and printing technology is driving the growth of the Metal 3D Printing market. A broader range of metals, including titanium, aluminum, stainless steel, and nickel-based alloys, can now be effectively printed. The development of advanced techniques like powder bed fusion and directed energy deposition has expanded the capabilities of Metal 3D Printing, allowing for increased efficiency and higher-quality output.

Metal 3D Printing offers unparalleled design freedom and customization. This is particularly crucial in industries requiring unique, specialized parts. Designers and engineers have the freedom to create complex geometries and intricate structures that were previously impossible or cost-prohibitive to produce.

Technology is revolutionizing supply chains by enabling on-demand production. This reduces inventory costs, eliminates the need for extensive warehousing, and minimizes material wastage. Companies can produce components as needed, providing agility and cost-efficiency.

Challenges do exist in the Metal 3D Printing market. High initial costs for equipment and materials, the need for skilled operators, and limitations in scaling production for mass markets are among the notable hurdles. The market is highly competitive, with numerous companies competing to innovate and expand their product portfolios.

Sustainability and Efficiency: As sustainability becomes increasingly critical, Metal 3D Printing aligns with eco-friendly manufacturing practices. It reduces material wastage, optimizes resource utilization, and has the potential to lower carbon footprints.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the "Metal 3D Printing Market."

https://www.techsciresearch.com/report/metal-3d-printing-market/17063.html

The global Metal 3D Printing market is segmented into product, form, application, and region. Based on product, the market is segmented into titanium and nickel. Based on form, the market is segmented into filament and powder. Based on application, the market is segmented into aerospace & defense, medical & dental, others Based on region, the market is further bifurcated into North America, Asia-Pacific, Europe, South America, Middle East & Africa.

Based on application, aerospace & defense dominated in the global Metal 3D Printing market in 2022. Aerospace and defense applications often demand components with intricate geometries and lightweight structures. Metal 3D Printing, with its ability to create highly complex designs and intricate internal features, aligns perfectly with the requirements of this sector. Parts produced using Metal 3D Printing are not constrained by traditional machining limitations, enabling the development of lightweight, high-performance aerospace components.

The aerospace and defense industry relies on performance-critical parts that must meet stringent standards for strength, durability, and reliability. Metal 3D Printing allows for the production of components with superior mechanical properties, making it well-suited for applications like jet engine parts, structural components, and rocket propulsion systems. These parts can withstand extreme conditions and deliver optimal performance, ensuring the safety and efficiency of aerospace and defense operations.

Key market players in the global Metal 3D Printing market are: -

- 3D Systems, Inc.

- Arcam AB

- GE Additive Manufacturing

- Hewlett-Packard

- Markforged, Inc.

- Renishaw plc

- SLM Solutions Group AG

- Stratasys Ltd.

- TRUMPF GmbH + Co. KG

- Velo3D, Inc.

Customers can also request for 10% free customization on this report.

“The Global Metal 3D Printing Market is experiencing rapid expansion, revolutionizing traditional manufacturing processes. This innovative technology creates metal components layer by layer, enabling complex and customized part production across various industries. With advancements in materials and printing techniques, a broader range of metals, including titanium and aluminum, are now printable. Metal 3D Printing offers unparalleled design freedom, customization, and the ability to produce on-demand, optimizing supply chains. Challenges include high initial costs and competition, but the market's potential for sustainability, efficiency, and innovative solutions make it a key player in reshaping the future of manufacturing.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based global management consulting firm.

“Metal 3D Printing Market – Global Industry Size, Share, Trends, Opportunity, and Forecast, By Product (Titanium, Nickel), By Form (Filament, Powder), By Application (Aerospace & Defense, Medical & Dental, Others), By Region, and By Competition, 2018-2028,” has evaluated the future growth potential of Global Metal 3D Printing Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Metal 3D Printing Market.

Contact

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York 10017

Tel: +1-646-360-1656

Email: sales@techsciresearch.com

Website: www.techsciresearch.com