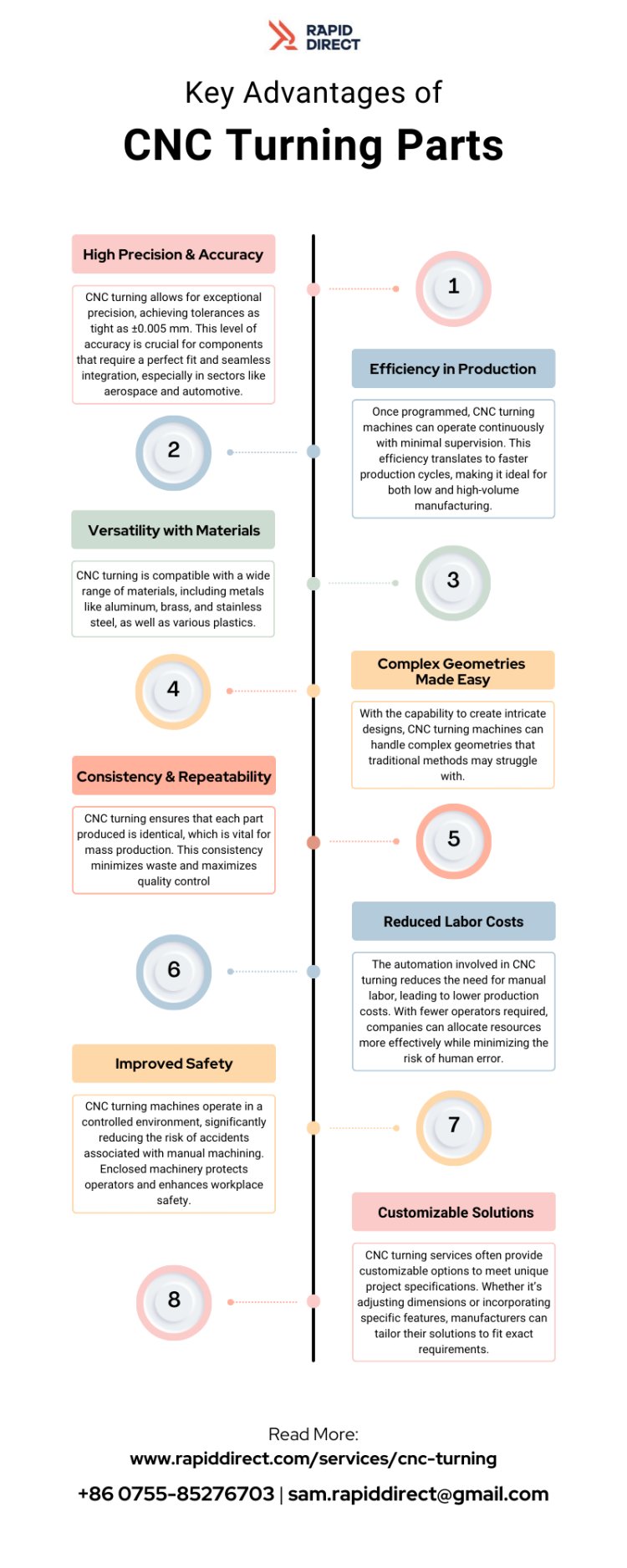

Key Advantages of CNC Turning Parts [Infographic]

Discover the key advantages of CNC turning parts through our informative infographic. Enhance your understanding of precision manufacturing and its benefits.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

![Key Advantages of CNC Turning Parts [Infographic]](https://blog.rackons.in/uploads/images/202409/image_750x_66e3d352a561e.jpg)

CNC turning parts are essential in modern manufacturing, providing precision and efficiency across various industries. Utilizing advanced computer-controlled lathes, CNC turning offers numerous advantages that enhance product quality and production speed. Here are the key benefits of CNC turning parts:

1. High Precision and Accuracy

CNC turning allows for exceptional precision, achieving tolerances as tight as ±0.005 mm. This level of accuracy is crucial for components that require a perfect fit and seamless integration, especially in sectors like aerospace and automotive.

2. Efficiency in Production

Once programmed, CNC turning machines can operate continuously with minimal supervision. This efficiency translates to faster production cycles, making it ideal for both low and high-volume manufacturing. Lead times can be as quick as one day, allowing companies to meet tight deadlines.

3. Versatility with Materials

CNC turning is compatible with a wide range of materials, including metals like aluminum, brass, and stainless steel, as well as various plastics. This versatility enables manufacturers to produce parts that meet specific performance requirements across different applications.

4. Complex Geometries Made Easy

With the capability to create intricate designs, CNC turning machines can handle complex geometries that traditional methods may struggle with. Features such as axial and radial holes, grooves, and flats can be produced with ease, ensuring that even the most demanding projects are completed successfully.

5. Consistency and Repeatability

CNC turning ensures that each part produced is identical, which is vital for mass production. This consistency minimizes waste and maximizes quality control, allowing manufacturers to maintain high standards across large batches.

6. Reduced Labor Costs

The automation involved in CNC turning reduces the need for manual labor, leading to lower production costs. With fewer operators required, companies can allocate resources more effectively while minimizing the risk of human error.

7. Improved Safety

CNC turning machines operate in a controlled environment, significantly reducing the risk of accidents associated with manual machining. Enclosed machinery protects operators and enhances workplace safety.

8. Customizable Solutions

CNC turning services often provide customizable options to meet unique project specifications. Whether it’s adjusting dimensions or incorporating specific features, manufacturers can tailor their solutions to fit exact requirements.

Conclusion

CNC turning parts offer a multitude of advantages that enhance manufacturing processes. From high precision and efficiency to material versatility and improved safety, these benefits make CNC turning an indispensable technology in various industries. For businesses looking to optimize their production capabilities, investing in CNC turning services can lead to significant improvements in both quality and output.

For more information visit https://tinyurl.com/4fss3kzh and call now at +86 0755-85276703 or email us at sam.rapiddirect@gmail.com

cncmachining

cncmachining