Innovative Uses of Roller Track in Modern Industrial Applications

Discover innovative uses of roller track systems in modern industrial applications, enhancing efficiency and productivity across various industries.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Introduction

The versatile roller tracks can be applied to almost any industry, trying to make material handling processes easier. Mounted on a track is a series of rollers allowing goods to move quickly and without much hustle. Roller tracks find varied applications in industrial settings, evidencing how greatly they benefit.

Manufacturing and Assembly Lines

Efficiency in Production

Roller tracks are of paramount importance in any manufacturing and assembling lines. It aids in the easy, quick movement of raw materials, components, and finished products in manufacturing, enhancing production efficiency. They reduce manual handling and transportation time to ensure a smooth workflow for the effective and timely completion of tasks.

Integration with Automation

Roller tracks can be integrated with automated systems, such as robotic arms and conveyor belts. This integration optimizes the production process, enabling precise and consistent handling of materials.

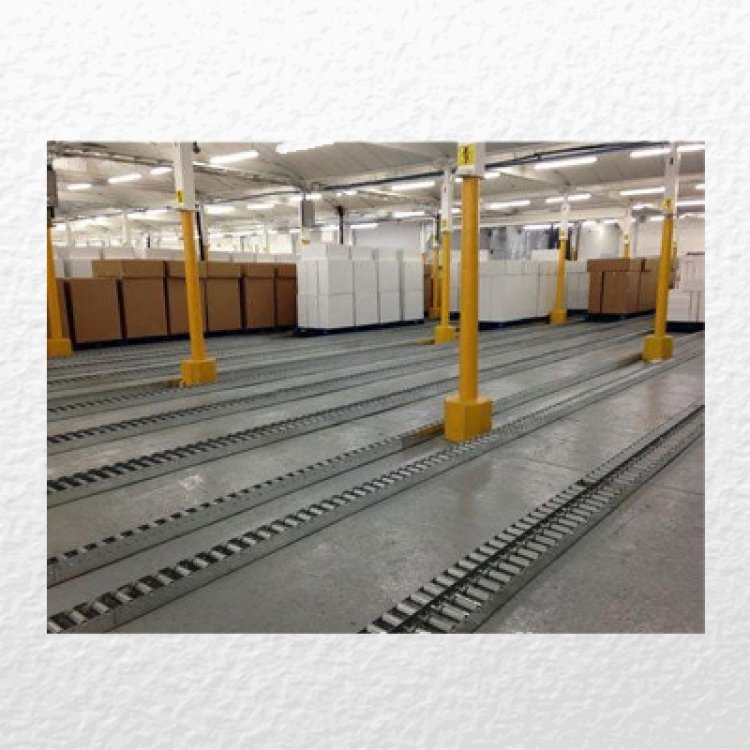

Warehousing and Distribution

Streamlined Material Handling

Roller tracks are essential in any warehousing or distribution center for easy handling of materials. They can easily be used to move bulky and heavy items to save the workers' physical strain. They ensure that goods move quickly and safely around the facility.

Space Optimization

Roller tracks help optimize storage space by facilitating easy access to stored items. They enable the efficient organization of goods, making retrieving and dispatching products easier. This organization maximizes the use of available space and enhances inventory management.

Logistics and Transportation

Efficient Loading and Unloading

Roller tracks in logistics and transport often form an essential part of the loading or unloading process. They are usually combined with conveyor systems to move goods from one vehicle to another or storage areas. This saves time and energy during loading or offloading and hence improves the efficiency of the logistics system in general.

Damage Reduction

In turn, roller tracks allow products to move smoothly and in a controlled manner, thus minimally causing damage during transport. Products will likely reach customers in the best condition, therefore enhancing satisfaction.

Customization and Versatility

Tailored Solutions

Roller track manufacturers offer various customizable options to meet specific industry needs. From varying roller sizes to different track materials, manufacturers can tailor roller tracks to suit particular applications.

Adaptability to Different Industries

Roller tracks are adaptable and used in various industries, including automotive, food and beverage, pharmaceuticals, and ecommerce. They are suitable for various materials and loads and essential to diverse industrial processes.

Conclusion

Roller tracks are one of the most significant tools in contemporary industrial operations, whose chief reasons for application are increasing efficiency, ensuring workplace safety, and enhancing productivity. Readying the right roller track manufacturers will ensure that your business gets the finest solutions compiled to suit your individual needs.