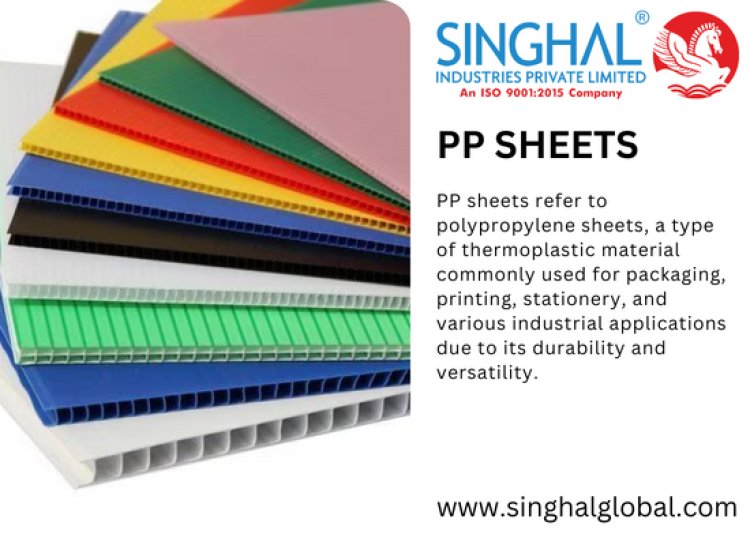

Exploring PP Sheet: Versatility, Applications, and Frequently Asked Questions

A PP sheet is a thermoplastic polymer made from the polymerization of propylene gas. It is known for its excellent mechanical properties, such as high impact resistance, good tensile strength, and low moisture absorption. PP sheets are available in various thicknesses, sizes, and colors, making them suitable for numerous applications.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

P P Sheets Manufacturer are a versatile, high-performance material widely used in various industries due to their unique properties. Known for their durability, flexibility, and resistance to various chemicals and environmental factors, PP sheets have become a staple in manufacturing, packaging, and other sectors. This article will explore the properties, applications, advantages, and frequently asked questions about PP sheets.

What is a PP Sheet?

A PP sheet is a thermoplastic polymer made from the polymerization of propylene gas. It is known for its excellent mechanical properties, such as high impact resistance, good tensile strength, and low moisture absorption. PP sheets are available in various thicknesses, sizes, and colors, making them suitable for numerous applications.

Properties of PP Sheets

Durability: Polypropylene Sheet Manufacturers are highly durable, making them suitable for long-term use in various applications. They can withstand significant wear and tear without losing their structural integrity.

Chemical Resistance: One of the most notable properties of PP sheets is their resistance to chemicals, including acids, bases, and solvents. This makes them ideal for use in environments where they might be exposed to harsh substances.

Low Density: PP sheets are lightweight due to their low density, which is beneficial in applications where weight reduction is crucial, such as in the automotive and aerospace industries.

Flexibility: Despite being durable, PP sheets are flexible, which allows them to be used in applications that require bending or molding.

Moisture Resistance: PP sheets have low moisture absorption, making them suitable for applications where they are exposed to water or humid conditions.

Thermal Stability: PP sheets can withstand a wide range of temperatures, maintaining their properties from -20°C to 100°C, which makes them suitable for various thermal environments.

Applications of PP Sheets

Packaging: Polypropylene Sheets 4x8 are extensively used in packaging due to their strength, flexibility, and resistance to chemicals. They are commonly used to make boxes, containers, and trays.

Automotive Industry: In the automotive sector, PP sheets are used for interior and exterior components due to their lightweight and durability, which contribute to fuel efficiency and longevity of the parts.

Construction: PP sheets are used in construction for applications like insulation, protective barriers, and panels. Their resistance to moisture and chemicals makes them ideal for these purposes.

Medical Industry: PP sheets are used in the medical field for making various equipment and packaging. Their chemical resistance and ability to be sterilized make them suitable for this industry.

Stationery and Office Supplies: PP sheets are used to make folders, binders, and other office supplies due to their durability and ease of fabrication.

Consumer Goods: Many consumer goods, such as household storage products, toys, and kitchenware, are made from PP sheets due to their safety and durability.

Advantages of PP Sheets

Cost-Effective: PP sheets are relatively inexpensive compared to other plastics with similar properties, making them a cost-effective solution for many applications.

Versatile: The ability to be molded, cut, and shaped into various forms makes PP sheets highly versatile.

Eco-Friendly: PP sheets are recyclable, contributing to environmental sustainability. They can be reprocessed and reused, reducing waste.

High Impact Resistance: PP sheets can absorb impacts without cracking or breaking, making them ideal for high-stress applications.

Ease of Fabrication: PP sheets can be easily fabricated using various techniques, including cutting, welding, and thermoforming, allowing for the creation of complex shapes and structures.

Safe for Food Contact: PP sheets are FDA approved for food contact, making them suitable for packaging and storage of food products.

Conclusion

PP sheets are an incredibly versatile and valuable material in various industries due to their excellent properties and wide range of applications. Their durability, chemical resistance, and flexibility make them a preferred choice for many manufacturers and consumers. Whether for packaging, automotive parts, construction materials, or medical equipment, PP sheets offer a reliable and cost-effective solution. By understanding their properties and benefits, businesses and individuals can make informed decisions when selecting materials for their needs.

Frequently Asked Questions (FAQ) About PP Sheets

Q1: What are the common sizes and thicknesses of PP sheets available?

A1: PP sheets are available in a wide range of sizes and thicknesses. Common thicknesses range from 0.5mm to 30mm, and they can be cut to various dimensions depending on the application requirements.

Q2: Can PP sheets be used outdoors?

A2: Yes, PP sheets can be used outdoors. They have good UV resistance, which prevents them from degrading quickly when exposed to sunlight. However, for prolonged outdoor use, UV-stabilized PP sheets are recommended.

Q3: How are PP sheets fabricated?

A3: PP sheets can be fabricated using various methods, including cutting, welding, and thermoforming. These processes allow for the creation of custom shapes and sizes tailored to specific applications.

Q4: Are PP sheets recyclable?

A4: Yes, PP sheets are fully recyclable. They can be reprocessed and reused in the production of new PP products, contributing to environmental sustainability.