Discover the Versatility and Benefits of PP Spunbond Nonwoven Fabric

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Introduction

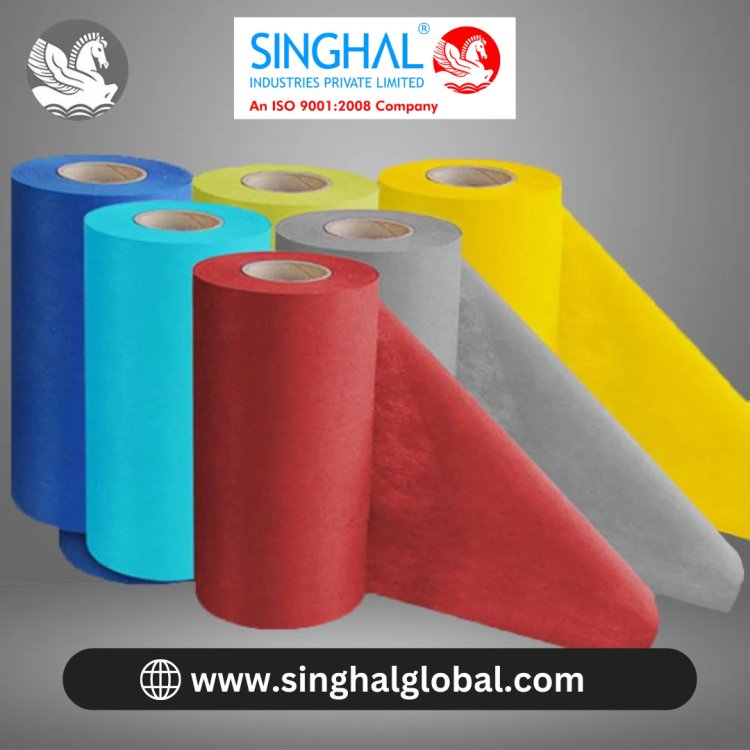

Polypropylene (PP) spunbond nonwoven fabric has revolutionized the textile industry with its remarkable properties and versatile applications. This fabric, made from thermoplastic polymer, offers numerous advantages that cater to a wide range of industries, from medical to agriculture and beyond. Singhal Industries, a leading manufacturer of flexible packaging products, delves into the fascinating world of Spunbond nonwoven Supplier India, exploring its uses, benefits, and the reasons it stands out as a superior material in various fields.

Understanding PP Spunbond Nonwoven Fabric

What is PP Spunbond Nonwoven Fabric?

PP spunbond nonwoven fabric is produced using a continuous process where polypropylene polymer is melted and extruded through fine nozzles. The resulting filaments are laid randomly on a conveyor belt, creating a web of interconnected fibers. These fibers are then bonded together using heat, pressure, or chemical bonding to form a strong, durable fabric.

Key Properties

- High Strength: The interlocking fibers provide excellent tensile strength and durability.

- Lightweight: Despite its strength, the fabric is lightweight, making it easy to handle and transport.

- Breathability: The porous structure allows air and moisture to pass through, enhancing comfort.

- Chemical Resistance: PP spunbond fabric is resistant to many chemicals, ensuring longevity in various environments.

- Hydrophobicity: It naturally repels water, making it suitable for moisture-sensitive applications.

- Eco-friendly: It is recyclable and can be produced using environmentally friendly processes.

Manufacturing Process

1. Raw Material Preparation

Polypropylene granules are sourced and prepared for the extrusion process. Quality control ensures that the raw materials meet the required standards for producing high-quality fabric.

2. Extrusion

The polypropylene granules are melted and extruded through fine nozzles to form continuous filaments. These filaments are rapidly cooled and stretched to align the polymer molecules, enhancing the fabric's strength and durability.

3. Web Formation

The extruded filaments are laid randomly on a moving conveyor belt to create a web of fibers. The random orientation of the fibers contributes to the fabric's isotropic properties, ensuring uniform strength in all directions.

4. Bonding

The web of fibers is bonded together using heat, pressure, or chemical bonding agents. This step solidifies the structure of the fabric, making it strong and durable. Different bonding techniques can be used to achieve various fabric characteristics, such as softness or stiffness.

5. Finishing

The bonded fabric is finished with treatments such as calendaring, embossing, or coating to enhance its properties and meet specific application requirements. Quality control checks are performed to ensure that the final product meets industry standards.

Applications of PP Spunbond Nonwoven Fabric

1. Medical and Healthcare

Spunbond non woven fabric manufacturer is widely used in the medical and healthcare industry due to its hygiene and barrier properties.

- Surgical Gowns and Drapes: Provides a sterile barrier against infections.

- Face Masks: Acts as a protective layer in medical masks, offering filtration and breathability.

- Protective Clothing: Used in disposable coveralls and lab coats for safety and hygiene.

- Medical Packaging: Ensures sterile conditions for medical instruments and devices.

2. Agriculture

In agriculture, PP spunbond fabric plays a crucial role in crop protection and soil management.

- Crop Covers: Protects plants from pests, frost, and excessive sunlight while maintaining air and moisture permeability.

- Weed Control: Acts as a barrier to prevent weed growth without the need for chemical herbicides.

- Mulch Fabric: Retains soil moisture and regulates temperature, promoting healthy plant growth.

- Greenhouse Shading: Provides shade and reduces temperature inside greenhouses, improving plant conditions.

3. Furniture and Upholstery

The furniture and upholstery industry benefits from the fabric's durability and aesthetic qualities.

- Mattress Covers: Provides a protective and breathable layer for mattresses.

- Upholstery Backing: Adds strength and stability to upholstered furniture.

- Dust Covers: Used for protecting furniture from dust and dirt during storage or transportation.

4. Construction

In construction, PP spunbond fabric is used for various applications due to its strength and environmental resistance.

- Roofing Underlayment: Acts as a moisture barrier and provides additional strength to roofing systems.

- House Wraps: Used as a breathable barrier to prevent moisture infiltration in building structures.

- Geotextiles: Reinforces soil and prevents erosion in landscaping and civil engineering projects.

5. Hygiene Products

The hygiene industry utilizes PP spunbond fabric for its softness and absorbency.

- Baby Diapers: Used as the top sheet layer for comfort and moisture management.

- Sanitary Napkins: Provides a soft and absorbent layer for feminine hygiene products.

- Adult Incontinence Products: Ensures comfort and dryness in incontinence pads and briefs.

6. Packaging

PP spunbond nonwoven fabric is also used in the packaging industry for its strength and flexibility.

- Reusable Shopping Bags: Provides a durable and eco-friendly alternative to single-use plastic bags.

- Protective Packaging: Used for wrapping and protecting delicate items during shipping.

- Agricultural Packaging: Ensures the safe transport and storage of agricultural products like grains and seeds.

Benefits of PP Spunbond Nonwoven Fabric

1. Cost-Effective

PP spunbond fabric is cost-effective due to its efficient production process and the relatively low cost of raw materials. Its durability and reusability further enhance its cost-efficiency, making it a preferred choice for many industries.

2. Versatility

The wide range of applications of PP spunbond fabric showcases its versatility. From medical use to construction and agriculture, this fabric can be tailored to meet the specific needs of various industries, making it an indispensable material.

3. Eco-Friendly

PP spunbond nonwoven fabric is recyclable and can be produced using environmentally friendly processes. Its reusability and durability reduce the environmental impact associated with single-use products, promoting sustainability.

4. Hygienic

The fabric's ability to provide a sterile barrier makes it ideal for medical and hygiene applications. Its breathability and moisture resistance ensure comfort and protection, essential qualities in healthcare settings.

5. Easy to Manufacture

The continuous production process of PP spunbond fabric ensures a consistent supply of high-quality material. The ability to customize the fabric's properties during production makes it easy to manufacture according to specific requirements.

6. Lightweight

Despite its strength, PP spunbond fabric is lightweight, which makes it easy to handle, transport, and apply. This quality is particularly beneficial in applications where weight is a critical factor, such as in the medical and packaging industries.

Conclusion

PP spunbond nonwoven fabric is a remarkable material that combines strength, durability, and versatility. Its wide range of applications, from medical and agriculture to construction and packaging, highlights its importance in various industries. Singhal Industries, a leading manufacturer of flexible packaging products, ensures the production of high-quality PP spunbond fabric that meets the diverse needs of their customers.

The benefits of Spunbond Exporter in Ahmedabad, including its cost-effectiveness, eco-friendliness, and hygienic properties, make it a superior choice for many applications. Whether you need a reliable material for protective clothing, crop covers, or reusable bags, PP spunbond nonwoven fabric provides an excellent solution. By choosing this innovative material, industries can enhance their operations while promoting sustainability and efficiency.

FAQS

What is PP spunbond nonwoven fabric?

PP spunbond nonwoven fabric is a versatile material made from polypropylene fibers that are bonded together using a heat and mechanical process, resulting in a durable and breathable fabric.

What are the advantages of PP spunbond nonwoven fabric?

PP spunbond fabric is lightweight, breathable, and resistant to moisture. It offers excellent strength, softness, and is recyclable, making it ideal for various applications.

Where is PP spunbond nonwoven fabric used?

It is used in agriculture (crop covers, mulching), medical (surgical gowns, masks), hygiene products (diapers, wipes), packaging, and construction (geotextiles) due to its diverse properties.

Is PP spunbond nonwoven fabric eco-friendly?

Yes, PP spunbond fabric can be recycled and is considered environmentally friendly compared to materials like PVC or traditional textiles due to its recyclability and production efficiency.

How can PP spunbond nonwoven fabric be customized?

PP spunbond fabric can be customized in terms of color, weight, and texture. It can also be treated for additional properties such as flame retardancy or UV resistance to meet specific application requirements.

![Renewed Remedies CBD Gummies [Hype Alert] Expert Reviews!](https://blog.rackons.in/uploads/images/202407/image_380x226_66950b05065c4.jpg)