Aluminium Price Trend Analysis: A Comprehensive Analysis

Aluminium Price Trend Analysis

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Aluminium, known for its versatility and lightweight properties, is a critical material used in various industries, including automotive, construction, aerospace, and packaging. The price of aluminium is subject to significant fluctuations due to a multitude of factors, including production costs, global demand, supply chain dynamics, and geopolitical events. This article provides a detailed analysis of aluminium price trend analysis, examining historical data, key factors influencing price changes, and future outlooks.

Historical Price Trends

Long-Term Trends

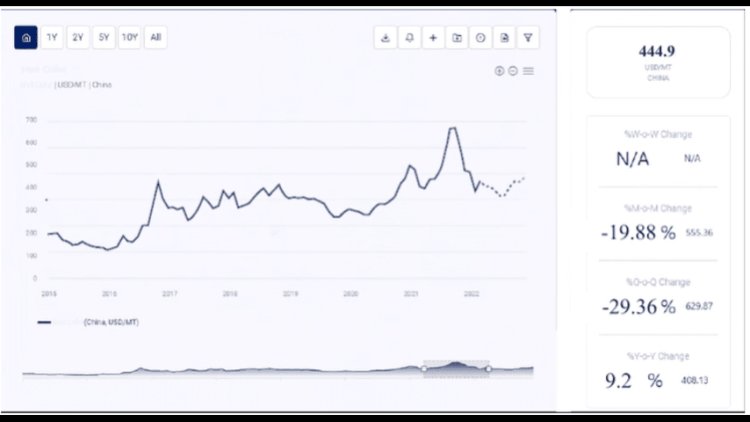

Over the past several decades, aluminium prices have shown both upward and downward trends, reflecting changes in global economic conditions, technological advancements, and shifts in supply and demand. The price of aluminium has generally increased over the long term, driven by rising demand from emerging markets and advancements in industrial applications.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/aluminum-price-trends/pricerequest

Periodic Volatility

The aluminium market is known for its periodic volatility, with prices experiencing sharp spikes and declines. Significant price fluctuations are often triggered by changes in production levels, energy costs, regulatory policies, and macroeconomic factors. For example, during the global financial crisis of 2008-2009, aluminium prices saw a significant drop due to reduced industrial activity and demand.

Key Factors Influencing Aluminium Prices

Production Costs

-

Raw Material Prices: The cost of raw materials, particularly bauxite and alumina, plays a crucial role in determining aluminium prices. Bauxite, the primary ore used to produce aluminium, must be refined into alumina before it can be smelted into aluminium. Fluctuations in the prices of these raw materials can directly impact the cost of aluminium production.

-

Energy Costs: Aluminium production is highly energy-intensive, with electricity being a significant component of production costs. Changes in energy prices, particularly electricity and natural gas, can have a substantial impact on aluminium prices. Regions with lower energy costs often have a competitive advantage in aluminium production.

Supply and Demand Dynamics

-

Global Demand: The demand for aluminium is driven by various industries, including transportation, construction, packaging, and electronics. Economic growth in emerging markets, such as China and India, has been a major driver of increased aluminium demand. Additionally, the shift towards lightweight and fuel-efficient vehicles has boosted demand for aluminium in the automotive sector.

-

Supply Levels: Aluminium supply is influenced by production levels, inventory levels, and recycling rates. Major aluminium-producing countries, including China, Russia, Canada, and India, play a significant role in determining global supply. Production cuts or increases in these countries can lead to significant price changes.

Government Policies and Regulations

-

Trade Policies: Trade policies, including tariffs, quotas, and trade agreements, can significantly impact aluminium prices. For instance, the imposition of tariffs on aluminium imports by the United States in 2018 led to increased prices in the domestic market.

-

Environmental Regulations: Environmental regulations aimed at reducing carbon emissions and promoting sustainability can affect aluminium production costs. For example, stricter environmental standards in China have led to the closure of inefficient and polluting smelters, impacting global supply and prices.

Geopolitical Events

Geopolitical events, such as conflicts, trade disputes, and sanctions, can disrupt aluminium supply chains and lead to price volatility. For example, sanctions on Russian aluminium producer Rusal in 2018 caused significant disruptions in the global aluminium market, leading to sharp price increases.

Recent Price Trends

Short-Term Price Movements

In recent years, aluminium prices have experienced notable short-term fluctuations. For instance, in 2020 and 2021, aluminium prices saw significant increases due to a combination of supply disruptions, rising demand, and higher production costs. The COVID-19 pandemic initially led to reduced industrial activity and lower demand, but as economies recovered, demand surged, leading to higher prices.

Impact of COVID-19

The COVID-19 pandemic had a profound impact on the aluminium market. Lockdowns and movement restrictions disrupted supply chains, leading to temporary shortages and price increases. Additionally, the pandemic highlighted the importance of supply chain resilience and the need for diversified sources of raw materials and production capabilities.

Case Studies of Major Aluminium Markets

China

China is the largest producer and consumer of aluminium, accounting for more than half of global production. The country's aluminium market is characterized by significant government intervention, with policies aimed at promoting domestic production and reducing environmental impact. In recent years, China's efforts to curb pollution and promote sustainability have led to the closure of inefficient smelters, impacting global supply and prices.

United States

The United States is a major consumer of aluminium, with significant demand from the automotive, aerospace, and construction industries. Trade policies, including tariffs on aluminium imports, have played a significant role in shaping the U.S. aluminium market. Additionally, the push towards renewable energy and electric vehicles is expected to drive future demand for aluminium in the United States.

Europe

Europe is a significant producer and consumer of aluminium, with major production centers in Germany, France, and Norway. The European aluminium market is influenced by environmental regulations and policies aimed at promoting recycling and sustainability. The European Green Deal, which aims to make Europe climate-neutral by 2050, is expected to impact aluminium production and demand in the region.

The Impact of Climate Change on Aluminium Production

Climate change poses a significant risk to aluminium production globally. Changes in temperature, precipitation patterns, and the frequency of extreme weather events can impact bauxite mining and aluminium production processes. Key impacts of climate change on aluminium production include:

- Energy Supply Disruptions: Extreme weather events, such as hurricanes and floods, can disrupt energy supply and increase production costs.

- Regulatory Changes: Governments may implement stricter environmental regulations to combat climate change, impacting production costs and supply chains.

- Sustainability Initiatives: The aluminium industry is increasingly focusing on sustainability initiatives, such as reducing carbon emissions and promoting recycling, to mitigate the impact of climate change.

Technological Innovations in Aluminium Production

Technological advancements are transforming the aluminium industry, offering solutions to some of the challenges faced by producers. Key innovations include:

- Energy Efficiency: Advances in energy-efficient smelting technologies can reduce production costs and carbon emissions.

- Recycling Technologies: Improved recycling technologies can increase the supply of secondary aluminium, reducing the need for primary production and lowering environmental impact.

- Automation and Digitalization: The adoption of automation and digitalization in production processes can improve efficiency, reduce costs, and enhance supply chain resilience.

Future Outlook

Demand Growth

The demand for aluminium is expected to continue growing, driven by factors such as urbanization, industrialization, and the shift towards sustainable and lightweight materials. Emerging markets, particularly in Asia, are expected to be major drivers of future demand.

Supply Challenges

Supply challenges, including resource availability, energy costs, and environmental regulations, will continue to impact aluminium prices. Ensuring a stable supply of raw materials and adopting sustainable production practices will be critical for the industry.

Technological Advancements

Technological advancements will play a key role in shaping the future of the aluminium industry. Innovations in energy efficiency, recycling, and digitalization will help producers meet growing demand while addressing environmental and cost challenges.

Conclusion

Aluminium prices are influenced by a complex interplay of factors, including production costs, global demand, supply chain dynamics, government policies, and geopolitical events. Understanding these factors is essential for stakeholders across the aluminium supply chain, from producers to consumers and policymakers. By adopting sustainable practices, investing in technology, and implementing effective policy interventions, it is possible to mitigate price volatility and ensure a stable supply of this critical material. As global challenges like climate change continue to evolve, the aluminium industry must adapt to maintain the delicate balance between supply and demand, ensuring that aluminium remains an affordable and accessible material for various applications worldwide.

leofrank

leofrank