ABS Plastic Sheets: A Comprehensive Guide

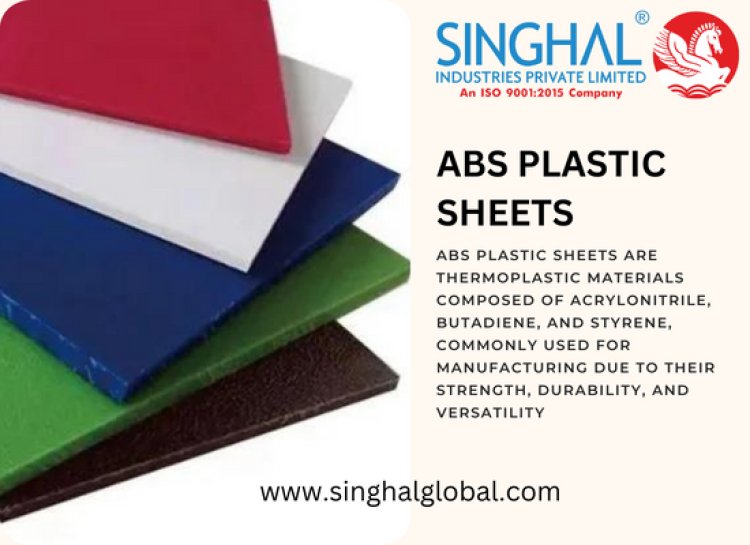

ABS plastic is a thermoplastic polymer known for its strength, rigidity, and impact resistance. It’s composed of three monomers: Acrylonitrile, Butadiene, and Styrene. The combination of these materials results in a durable plastic that’s ideal for various industrial and commercial purposes.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

In the world of manufacturing, 4x8 ABS Sheet Manufacturers in Gujarat are ubiquitous. Whether you’re crafting prototypes, constructing automotive parts, or creating consumer products, ABS (Acrylonitrile Butadiene Styrene) sheets offer a versatile solution with a wide range of applications. In this guide, we delve into everything you need to know about ABS plastic sheets, from their composition and properties to their uses and frequently asked questions.

Understanding ABS Plastic Sheets

ABS plastic is a thermoplastic polymer known for its strength, rigidity, and impact resistance. It’s composed of three monomers: Acrylonitrile, Butadiene, and Styrene. The combination of these materials results in a durable plastic that’s ideal for various industrial and commercial purposes.

Properties of ABS Plastic Sheets

Strength and Durability: 4x8 Sheet of ABS Plastic Exporters in Ahmedabad are renowned for their toughness, making them suitable for applications requiring impact resistance.

Flexibility: Despite its rigidity, ABS plastic sheets offer a degree of flexibility, allowing them to bend without breaking.

Chemical Resistance: ABS is resistant to many chemicals, making it suitable for use in environments where exposure to harsh substances is common.

Heat Resistance: While ABS has a relatively low melting point compared to other plastics, it still maintains its structural integrity at temperatures up to 176°F (80°C), making it suitable for a wide range of temperature conditions.

Ease of Machining: ABS plastic sheets can be easily machined, drilled, and sawed, allowing for precise customization to meet specific project requirements.

Applications of ABS Plastic Sheets

ABS Manufacturers in India find application across various industries due to their versatility and durability:

Automotive Industry: ABS sheets are used in automotive interiors, exterior trims, and under-the-hood components due to their impact resistance and ability to withstand temperature fluctuations.

Electronics: ABS is commonly used in the manufacture of electronic enclosures and housings due to its electrical insulation properties and ability to be molded into intricate shapes.

Consumer Goods: From household appliances to toys and kitchenware, ABS plastic sheets are prevalent in the production of consumer goods due to their aesthetic appeal and durability.

Prototyping and Model Making: ABS sheets are popular in the prototyping and model-making industry due to their ease of machining and ability to replicate intricate details.

Construction and Architecture: ABS plastic sheets are used in construction for interior design elements, such as wall panels, signage, and decorative features, thanks to their durability and aesthetic appeal.

Conclusion

ABS plastic sheets are a versatile material with a wide range of applications across various industries. From automotive components to consumer products and construction materials, ABS offers durability, impact resistance, and ease of customization. Understanding the properties and applications of ABS plastic sheets can help manufacturers and designers choose the right material for their specific needs, ensuring the success of their projects.

FAQs About ABS Plastic Sheets

1. Are ABS plastic sheets recyclable?

Yes, ABS plastic sheets are recyclable. However, the recycling process can be more challenging compared to other plastics due to ABS’s complex composition. It’s essential to consult with recycling facilities that accept ABS plastic to ensure proper disposal and recycling.

2. Can ABS plastic sheets be painted?

Yes, ABS plastic sheets can be painted using acrylic or enamel paints. However, proper surface preparation, such as cleaning and sanding, is necessary to ensure adhesion. Additionally, using a primer designed for use with plastics can help improve paint adhesion and durability.

3. Are ABS plastic sheets food-safe?

ABS plastic is generally considered food-safe, but it’s essential to verify that the specific ABS sheet you’re using complies with relevant food safety regulations. Look for ABS sheets that are labeled as food-grade or NSF-certified for peace of mind when using them in food-related applications.

4. What are the differences between ABS and PVC plastic sheets?

While both ABS and PVC (Polyvinyl Chloride) are thermoplastics, they have different properties and applications. ABS is known for its toughness and impact resistance, making it suitable for applications where durability is essential. PVC, on the other hand, is known for its chemical resistance and flame-retardant properties, making it ideal for piping, construction materials, and medical devices.