16 DPA Manufacturing Plant Project Report 2024: Process, Challenges and Benefits

Explore the 16 DPA Manufacturing Plant Project Report, detailing market insights, production processes, and sustainability strategies

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

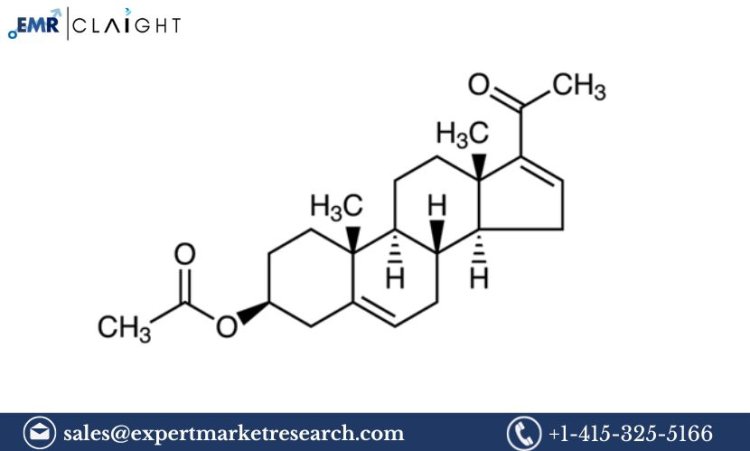

The chemical compound 16 DPA (16-Docosapentaenoic Acid) has garnered attention in various industries, particularly in the fields of pharmaceuticals, nutraceuticals, and cosmetics. Known for its beneficial properties, 16 DPA is often used as an omega-3 fatty acid, contributing to health benefits such as improved cardiovascular health and anti-inflammatory effects. Establishing a manufacturing plant for 16 DPA presents an exciting opportunity to meet the rising demand for this compound. This 16 DPA Manufacturing Plant Project Report outlines the essential components, market insights, and challenges involved in setting up a successful production facility.

Market Overview

The global demand for omega-3 fatty acids, including 16 DPA, is on the rise due to increasing awareness of their health benefits. As consumers become more health-conscious and seek dietary supplements that support well-being, the market for 16 DPA is expected to grow. Applications extend to:

- Nutraceuticals: Supplements and health products focusing on heart health and overall wellness.

- Pharmaceuticals: Drug formulations that utilize 16 DPA for its anti-inflammatory properties.

- Cosmetics: Beauty products that benefit from the moisturizing and skin-repairing effects of omega-3 fatty acids.

The expanding applications across these sectors contribute to a promising market outlook for 16 DPA.

Get a Free Sample Report with Table of Contents@

Understanding 16 DPA

16 DPA is a long-chain polyunsaturated fatty acid that plays a crucial role in various biological processes. Its anti-inflammatory properties make it particularly valuable in treating and preventing chronic diseases. The increasing awareness of dietary fats and their impact on health has led to a surge in demand for omega-3 fatty acids, including 16 DPA.

Key Components of a 16 DPA Manufacturing Plant Project

Establishing a manufacturing plant for 16 DPA requires careful planning and consideration of several critical components:

1. Raw Material Sourcing

The primary raw materials for producing 16 DPA are marine oils, particularly those rich in omega-3 fatty acids. Key considerations include:

- Supplier Relationships: Establish reliable partnerships with suppliers of high-quality marine oils to ensure consistent production.

- Quality Control: Implement strict quality assurance measures to evaluate the purity and safety of incoming raw materials.

2. Facility Design and Requirements

The manufacturing facility must be designed to ensure compliance with safety regulations and efficient production. Important factors include:

- Production Area: A clean and organized production environment that accommodates equipment and processing activities.

- Laboratory Space: A dedicated area for quality control testing, ensuring compliance with industry standards.

- Storage Facilities: Proper storage for raw materials and finished products to maintain quality and safety.

An effective facility layout minimizes contamination risks and enhances operational efficiency.

3. Machinery and Equipment

Investing in the right machinery is crucial for producing 16 DPA efficiently. Essential equipment includes:

- Extraction Systems: Equipment to extract omega-3 fatty acids from marine oils using techniques such as cold pressing or solvent extraction.

- Purification Units: Systems for refining and purifying extracted oils to obtain high-quality 16 DPA.

- Packaging Machines: Automated packaging systems to ensure the product is sealed in moisture-proof and airtight containers.

Choosing reliable and efficient machinery can enhance productivity and reduce operational costs.

4. Production Process

The production process for 16 DPA generally involves several stages:

- Extraction: Marine oils are extracted using appropriate methods to obtain omega-3 fatty acids.

- Purification: The extracted oil undergoes purification to remove impurities and concentrate the 16 DPA content.

- Formulation and Packaging: The purified product is formulated for specific applications and packaged for distribution.

Each step requires careful monitoring to maintain product quality and integrity.

5. Quality Control and Compliance

Ensuring product quality and safety is paramount in the manufacturing of 16 DPA. Implementing a robust quality control program involves:

- Regular Testing: Conducting microbiological and chemical analyses to ensure the product meets safety and quality standards.

- Regulatory Compliance: Adhering to relevant regulations and obtaining necessary certifications to ensure the product is safe for consumption.

Implementing stringent quality control measures enhances customer trust and product credibility.

Benefits of Establishing a 16 DPA Manufacturing Plant

- Growing Market Demand: The increasing awareness of health benefits associated with omega-3 fatty acids presents a significant market opportunity.

- Product Versatility: 16 DPA can be utilized in various industries, providing manufacturers with multiple revenue streams.

- Innovation Potential: The ongoing research and development in omega-3 applications allow for product innovation and differentiation.

- Support for Sustainable Practices: Sourcing raw materials responsibly can align the manufacturing process with sustainable practices.

Environmental and Social Considerations

Sustainability is a growing concern in the manufacturing sector. Adopting environmentally friendly practices can enhance the brand's reputation and promote social responsibility:

- Sustainable Sourcing: Partnering with suppliers committed to sustainable fishing practices ensures the long-term viability of marine resources.

- Waste Management: Implementing effective waste disposal and recycling practices to minimize environmental impact.

- Community Engagement: Contributing to local communities through employment opportunities and supporting sustainable initiatives.

Key Challenges and Solutions

Setting up a 16 DPA manufacturing plant presents several challenges, including:

- High Initial Investment: The cost of establishing the facility and purchasing equipment can be substantial.

- Regulatory Compliance: Navigating the complex landscape of food and health regulations can be daunting.

- Market Competition: Competing with established players in the omega-3 market requires innovative marketing strategies.

Solutions: Conducting thorough market research and financial planning can help mitigate investment challenges. Engaging with industry experts for regulatory compliance guidance can streamline the process. Focusing on product differentiation and quality can provide a competitive edge.

Marketing and Distribution Strategies

To successfully market 16 DPA products, effective marketing and distribution strategies are crucial:

- Targeting Health-conscious Consumers: Building a brand that emphasizes the health benefits of 16 DPA can attract health-conscious consumers.

- Collaborating with Retailers: Partnering with health food stores, pharmacies, and online retailers can expand product reach.

- Educational Campaigns: Informing consumers about the benefits of omega-3 fatty acids through workshops, webinars, and informative content can enhance brand visibility.

By implementing these strategies, manufacturers can improve their market presence and drive sales.

FAQ

Q1. What is 16 DPA?

16 DPA is a long-chain polyunsaturated fatty acid known for its omega-3 content and health benefits.

Q2. What are the applications of 16 DPA?

16 DPA is used in nutraceuticals, pharmaceuticals, and cosmetics due to its anti-inflammatory properties and health benefits.

Q3. How is 16 DPA produced?

Production involves extracting omega-3 fatty acids from marine oils, purifying them, and packaging the final product.

Q4. What equipment is necessary for a 16 DPA manufacturing plant?

Essential equipment includes extraction systems, purification units, and packaging machines.

Q5. How can manufacturers ensure the quality of 16 DPA?

Implementing regular testing, conducting quality analyses, and adhering to regulatory standards ensures product quality.

Q6. Are there environmental considerations in producing 16 DPA?

Yes, sustainable sourcing, waste management, and community engagement are important for responsible production.

Q7. What are the main challenges in setting up a 16 DPA manufacturing plant?

Challenges include high initial investment, regulatory compliance, and competition in the market.

Q8. How can manufacturers effectively market 16 DPA products?

Targeting health-conscious consumers, collaborating with retailers, and running educational campaigns can enhance market visibility.

Related Reports

https://www.expertmarketresearch.com/reports/thailand-waterproofing-market

https://www.expertmarketresearch.com/articles/top-5-companies-in-the-global-organic-pet-food-market

https://www.expertmarketresearch.com/reports/earphones-and-headphones-market-report

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

lewisfernandas

lewisfernandas