What Makes PAM Essential for Modern Drilling?

Learn how it stabilizes mud, reduces friction, and prevents wellbore collapse, ensuring safer and faster drilling operations.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

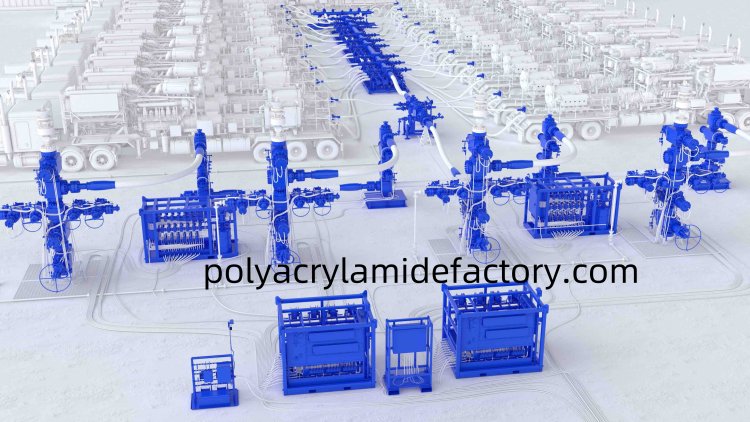

As a leading innovator among oilfield polyacrylamide manufacturers, we provide high-performance polymer solutions designed to revolutionize drilling, fracturing, and enhanced oil recovery (EOR). Our advanced polyacrylamide (PAM) formulations optimize viscosity, stabilize wellbores, and improve hydrocarbon extraction efficiency, ensuring cost-effective and sustainable operations across diverse geological conditions. Trusted by global energy leaders, our products address critical challenges in fluid loss control, proppant transport, and water management, while aligning with stringent environmental standards.

Cutting-Edge Solutions for Drilling & Fracturing

Oilfield polyacrylamide serves as a cornerstone in drilling fluid additives, enhancing mud stability, reducing friction, and preventing wellbore collapse. Its ability to carry cuttings and lubricate drill bits minimizes equipment wear and operational risks . In hydraulic fracturing, PAM-based fluids improve fracture conductivity, suspend proppants efficiently, and reduce energy consumption through low-residue formulations, ensuring optimal reservoir stimulation .

Maximizing Oil Recovery with Precision

Our PAM products play a pivotal role in polymer flooding, a key EOR technique. By adjusting injected water viscosity and mobility ratios, they expand sweep efficiency, displacing residual oil trapped in low-permeability zones. This technology significantly boosts recovery rates while maintaining reservoir integrity . Customized molecular structures, tailored to salinity and temperature variations, ensure adaptability to complex reservoirs .

Eco-Conscious Performance

Aligned with global sustainability goals, our oilfield polyacrylamide integrates biodegradable components and low-toxicity chemistries. These innovations reduce environmental impact, support closed-loop water recycling, and comply with evolving regulatory frameworks, enabling clients to balance productivity with ecological responsibility .

End-to-End Technical Expertise

Beyond product supply, we offer laboratory testing, on-site diagnostics, and real-time performance monitoring. Our cloud-based analytics optimize dosage and fluid compatibility, while tailored application strategies address challenges like clay stabilization and thermal degradation .

Transform your oilfield operations with industry-leading expertise. Visit https://www.polyacrylamidefactory.com to explore solutions that redefine efficiency and sustainability.