What is Precision Machined Casting? A Perfect Blend of Casting and CNC Machining

Discover how precision machined casting combines casting and CNC machining for high-accuracy, cost-effective components.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

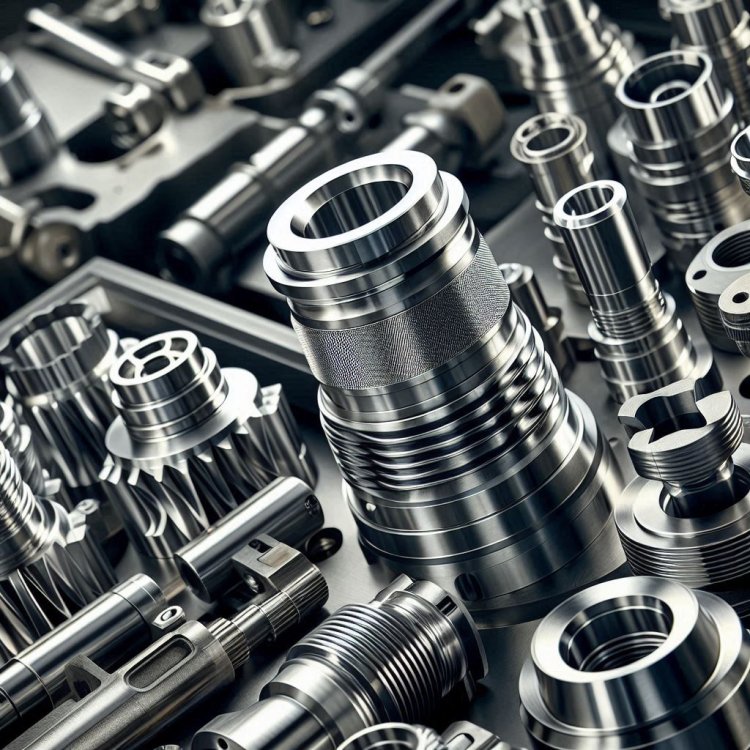

Precision machined casting is the combination of high-quality casting processes—such as investment or sand casting—with CNC machining to achieve tight tolerances and exact specifications. After the initial casting, the part undergoes secondary machining operations to refine critical surfaces, drill holes, and ensure dimensional accuracy. This hybrid approach allows manufacturers to produce complex, near-net-shape components cost-effectively while meeting the demanding standards of industries like aerospace, automotive, and hydraulics. It offers the best of both worlds: the efficiency of casting and the accuracy of precision machining.

Benefits of Precision Machined Casting in High-Performance Applications

Precision machined casting is widely used in applications where strength, durability, and dimensional accuracy are non-negotiable. By starting with a robust casting and applying targeted machining only where needed, manufacturers can reduce material waste, lower production costs, and improve efficiency. These parts offer excellent repeatability, consistent quality, and tight tolerances—often within microns—which is essential for critical components such as pump bodies, engine parts, and industrial valves. The process also supports a wide variety of materials, including stainless steel, aluminum, and exotic alloys.

Industries That Rely on Precision Machined Castings

Many high-tech and heavy-duty industries depend on precision machined castings to keep operations running smoothly. In aerospace, they are used for turbine components and structural parts where performance under pressure is vital. The automotive sector relies on them for gear housings, brake components, and engine brackets. Industrial machinery and pump manufacturers also favor these castings for their balance of strength and accuracy. Because the process ensures high-quality parts that meet strict engineering standards, it is a preferred solution across sectors where failure is not an option.

![Men's Vitality Reviews [TRUTH or LEGIT] Does It Really Work or Fake Results?](https://blog.rackons.in/uploads/images/202506/image_380x226_683e86f5cc81b.jpg)