Understanding HDPE T-Rib Liner Sheets: A Comprehensive Guide

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

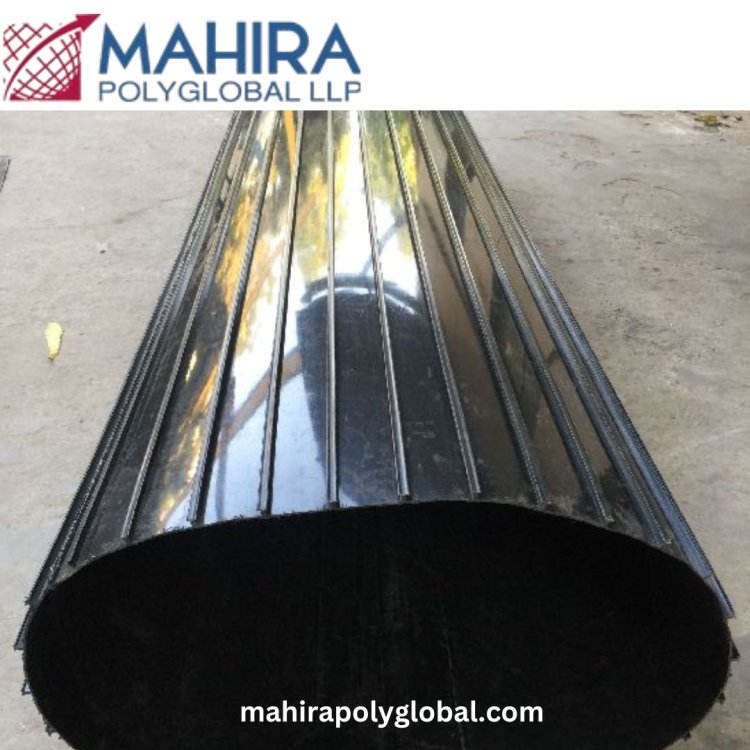

HDPE T-Rib liner sheets have become increasingly popular in various industries due to their durability, versatility, and effectiveness in protecting infrastructure. Made from high-density polyethylene (HDPE), these liner sheets are designed with a unique ribbed structure that enhances their strength and stability. Whether for use in landfills, reservoirs, or agricultural applications, T-Rib HDPE liner sheets offer a reliable solution to prevent leaks and protect the environment. This Mahira Polyglobal LLP will explore the characteristics, advantages, installation methods, and specific applications of HDPE T-Rib liner sheets in India and beyond.

What Are HDPE T-Rib Liner Sheets?

HDPE T-Rib liner sheets are specifically engineered products that utilize high-density polyethylene, a thermoplastic known for its robustness and resistance to environmental stress. The T-Rib design consists of raised ribs that provide added structural integrity, which helps in distributing stress evenly across the surface. This unique design feature is beneficial in applications where the liner must endure pressure from water or other materials. The ribbed pattern also facilitates drainage, preventing the accumulation of water, which can lead to issues such as mold and structural failure.

These liner sheets are often employed in scenarios requiring high-performance barriers, including landfill lining, pond and reservoir lining, and mining applications. Their resilience against harsh environmental conditions, including UV exposure and chemical corrosion, makes them suitable for long-term use. Additionally, the ease of installation and maintenance of T-Rib HDPE liner sheets further contribute to their growing popularity in various industries.

Advantages of T-Rib HDPE Liner Sheets

One of the primary advantages of T-Rib HDPE liner sheets is their exceptional durability. These liners can withstand significant physical stress, making them ideal for applications in environments where traditional liners may fail. The ribbed design not only increases strength but also enhances resistance to punctures and tears, ensuring long-lasting performance.

Another significant benefit of HDPE T-Rib liner sheets is their excellent waterproofing capabilities. The impermeable nature of HDPE effectively prevents the leakage of liquids, making these liners an excellent choice for applications involving hazardous materials or wastewater. This characteristic is particularly important in environmental protection, as it helps prevent the contamination of soil and groundwater resources.

Moreover, T-Rib HDPE liner sheets are environmentally friendly, as they can be recycled at the end of their life cycle. Many manufacturers are committed to sustainable practices, producing liners that can be repurposed or recycled, thus minimizing waste. This commitment to sustainability resonates with organizations and industries aiming to reduce their environmental impact.

Applications of HDPE T-Rib Liner Sheets

The applications for HDPE T-Rib liner Sheets Installation are vast and varied. In the construction and civil engineering sectors, they are commonly used for landfill lining. The ribbed structure provides added strength to withstand the pressure exerted by waste materials, while the impermeable surface prevents leachate from contaminating the surrounding environment. This application is critical for protecting groundwater and maintaining compliance with environmental regulations.

In agriculture, T-Rib HDPE liner sheets are used in the construction of water storage ponds and reservoirs. Their ability to prevent water loss through seepage makes them an ideal solution for irrigation systems, particularly in arid regions. Farmers can maximize water retention and reduce evaporation, ensuring a reliable water supply for their crops.

Mining operations also benefit from HDPE T-Rib liner sheets, as they are employed in tailings ponds and waste containment areas. The liners serve as a barrier to prevent harmful substances from leaching into the surrounding soil and waterways, contributing to sustainable mining practices. By utilizing these liners, companies can mitigate environmental risks and comply with strict regulations regarding waste management.

Installing HDPE T-Rib Liner Sheets

The installation process for HDPE T-Rib liner sheets is relatively straightforward, making them a preferred choice for many contractors and engineers. Proper installation is crucial for ensuring the effectiveness of the liner and maximizing its lifespan. Here are the general steps involved in the installation process:

-

Site Preparation: Before installation, the site must be cleared of debris, rocks, and sharp objects that could damage the liner. The ground should be leveled and compacted to create a smooth surface for the liner.

-

Liner Placement: Once the site is prepared, the T-Rib HDPE liner sheets are rolled out across the area. It's essential to ensure that the sheets overlap adequately to prevent any gaps that could allow leakage.

-

Securing the Liner: The liner must be secured in place using mechanical fasteners or adhesive, depending on the specific requirements of the project. The ribbed design can be beneficial here, as it provides additional grip to help keep the liner in position.

-

Testing for Integrity: After installation, a thorough inspection should be conducted to ensure there are no punctures or gaps in the liner. A water test may be performed to check for leaks, ensuring that the liner will function effectively in its intended application.

-

Covering the Liner: In applications such as landfills, the HDPE liner may need to be covered with additional materials, such as soil or aggregate, to protect it from damage and UV exposure.

Following these steps will help ensure a successful installation of HDPE T-Rib liner sheets, allowing them to perform optimally for their intended use.

The Market for HDPE T-Rib Liner Sheets in India

In India, the demand for T-Rib HDPE liner sheets has grown significantly in recent years due to increasing environmental awareness and the need for sustainable infrastructure solutions. Various industries, including construction, agriculture, and waste management, are recognizing the benefits of using HDPE liners for effective waste containment and resource conservation.

The growth of urbanization and industrialization has also contributed to the rising need for effective waste management solutions. As more landfills are constructed to handle increasing waste volumes, the importance of reliable liner systems becomes paramount. T-Rib HDPE liner sheets are being used in many new landfill projects across the country, contributing to better waste management practices and environmental protection.

Moreover, with government initiatives focused on sustainable development, there is a growing emphasis on using eco-friendly materials in construction and infrastructure projects. This trend further boosts the demand for HDPE T-Rib liners, as they offer both durability and environmental benefits.

Challenges and Considerations

While HDPE T-Rib liner sheets offer numerous advantages, there are also challenges and considerations to keep in mind. One of the primary concerns is the initial cost of the materials and installation. While the long-term benefits and durability often outweigh the initial investment, budget constraints can be a significant factor for some projects.

Another consideration is the need for skilled labor for proper installation. While the installation process is relatively straightforward, ensuring that the liners are installed correctly is essential for their effectiveness. Projects may require experienced contractors who are familiar with HDPE liner installation to avoid costly mistakes.

Additionally, the availability of quality HDPE T-Rib liner sheets from reputable manufacturers is crucial. Organizations must ensure that they source materials from reliable suppliers to guarantee the quality and performance of the liners. Researching suppliers, checking certifications, and seeking recommendations can help in selecting the best options available.

Conclusion

In summary, HDPE T-Rib liner sheets provide an effective, durable, and environmentally friendly solution for a wide range of applications, from landfill lining to agricultural water retention. Their unique ribbed design enhances their strength and performance, making them a preferred choice in many industries. As the demand for sustainable infrastructure solutions continues to rise, HDPE T-Rib liners are poised to play a critical role in protecting the environment and promoting responsible resource management. By investing in quality materials and proper installation, industries can ensure that they maximize the benefits of T-Rib HDPE liner sheets for their specific applications.

Frequently Asked Questions (FAQs)

Q1: What are the main advantages of using HDPE T-Rib liner sheets?

HDPE T-Rib liner sheets offer several advantages, including excellent durability, waterproofing capabilities, resistance to UV exposure and chemical corrosion, and eco-friendliness due to their recyclability. Their unique ribbed design enhances structural integrity and prevents leakage, making them ideal for various applications.

Q2: How are HDPE T-Rib liner sheets installed?

The installation process involves site preparation, placing the liner sheets, securing them in position, testing for integrity, and covering the liner if necessary. Proper installation is crucial for maximizing the effectiveness and lifespan of the liners.

Q3: Are HDPE T-Rib liner sheets suitable for agricultural applications?

Yes, T-Rib HDPE liner sheets are well-suited for agricultural applications, such as water storage ponds and irrigation systems. Their impermeable nature helps retain water and reduces evaporation, ensuring reliable water supply for crops.

Q4: How do I select a reliable supplier for HDPE T-Rib liner sheets in India?

When choosing a supplier, consider their reputation, product quality, customer reviews, and range of services offered. Look for suppliers who prioritize sustainability and have a proven track record in providing high-quality HDPE liners.