Understanding Danger Tape Roll: A Vital Tool for Safety

Danger tape rolls, including electrical warning tape and safety caution tape, are vital tools for enhancing safety across various industries. Their bright colors, durability, and ease of use make them effective in marking hazardous areas and communicating risks. By adopting best practices in the placement and use of danger tape, organizations can significantly improve workplace safety and reduce the likelihood of accidents. Investing in danger tape is not just a regulatory requirement but a commitment to creating a safer environment for everyone involved.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

In various industries, ensuring safety is paramount, especially when dealing with potential hazards. One essential tool that plays a crucial role in maintaining safety is the danger tape roll. Also known as electrical warning tape or safety caution tape, this versatile product helps alert individuals to hazards and prevents accidents. This article will explore the features, benefits, applications, and best practices for using danger tape rolls, emphasizing their importance in safety management.

What is a Danger Tape Roll?

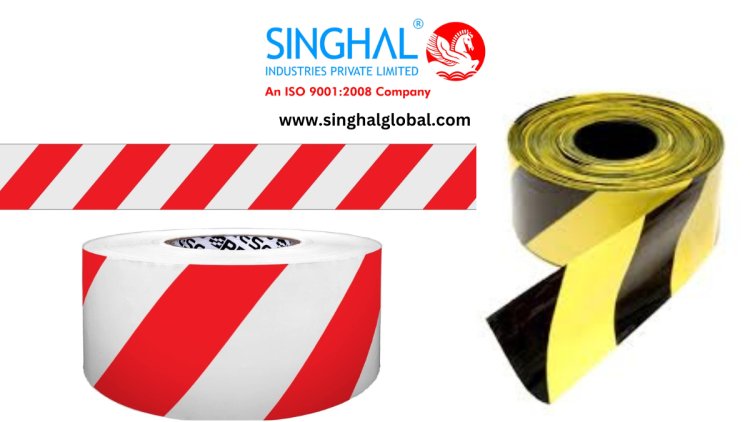

A danger tape roll is a brightly colored tape used to indicate hazardous areas or convey warnings. Typically made from durable plastic materials, this tape is often printed with clear messages such as "Danger," "Caution," or "Warning." Its vibrant colors—commonly yellow, red, or orange—are designed to catch attention and provide immediate recognition of potential dangers.

Key Features of Danger Tape Rolls

-

Visibility: The bright colors and bold text make danger tape rolls highly visible, even from a distance. This is crucial in environments where quick recognition of hazards is necessary.

-

Durability: Made from high-quality materials, danger tape is designed to withstand various weather conditions, making it suitable for both indoor and outdoor use.

-

Versatility: Danger tape rolls can be used in various applications, from construction sites to industrial facilities, electrical work, and public events.

-

Easy to Use: The tape can be easily unrolled and cut to the desired length, allowing for quick setup in emergency situations or during safety inspections.

Benefits of Using Danger Tape Rolls

-

Enhanced Safety: By clearly marking hazardous areas, danger tape helps prevent accidents and injuries, promoting a safer work environment.

-

Cost-Effective: Compared to other safety measures, using danger tape rolls is an inexpensive solution that can significantly reduce the risk of accidents.

-

Clear Communication: The messages printed on danger tape provide immediate information about potential hazards, ensuring that individuals are aware of the risks.

-

Regulatory Compliance: Many industries are required to adhere to safety regulations. Using danger tape helps organizations comply with these regulations by clearly marking hazardous areas.

Applications of Danger Tape Rolls

Danger tape rolls are utilized across various sectors, reflecting their versatility:

-

Construction Sites: On construction sites, danger tape is used to cordon off dangerous areas, such as excavation sites, to prevent unauthorized access and protect workers.

-

Electrical Work: In electrical installations, Electrical warning tape is essential for marking live wires, exposed electrical components, and areas where electrical work is being performed.

-

Industrial Facilities: Factories and manufacturing plants use Safety caution tape to designate hazardous zones, including areas with heavy machinery or chemical spills.

-

Public Events: At public gatherings, danger tape can help control crowds and mark off areas that are off-limits for safety reasons.

Best Practices for Using Danger Tape Rolls

-

Proper Placement: Ensure that the tape is placed at eye level or in areas where individuals are likely to notice it. This maximizes visibility and effectiveness.

-

Clear Messaging: Use tape with clear, concise messages that convey the nature of the hazard. Avoid using jargon or complex language that may confuse individuals.

-

Regular Inspections: Regularly check the condition of the tape to ensure it remains visible and effective. Replace any damaged or faded tape promptly.

-

Training and Awareness: Educate employees and individuals about the significance of danger tape and the hazards it represents. This helps reinforce a culture of safety.

Frequently Asked Questions (FAQs)

1. What materials are danger tape rolls made from?

Answer: Danger tape rolls are typically made from durable plastic materials, such as polyethylene or vinyl, which provide weather resistance and long-lasting visibility.

2. Can danger tape be used outdoors?

Answer: Yes, danger tape is designed to withstand various weather conditions, making it suitable for both indoor and outdoor use.

3. How effective is danger tape in preventing accidents?

Answer: While danger tape is not a physical barrier, its visibility and clear messaging significantly reduce the risk of accidents by alerting individuals to potential hazards.

4. Are there different types of danger tape available?

Answer: Yes, danger tape comes in various colors and messages. Electrical warning tape specifically indicates electrical hazards, while safety caution tape can convey a broader range of warnings.

Summary

Danger tape rolls, including electrical warning tape and safety caution tape, are vital tools for enhancing safety across various industries. Their bright colors, durability, and ease of use make them effective in marking hazardous areas and communicating risks. By adopting best practices in the placement and use of danger tape, organizations can significantly improve workplace safety and reduce the likelihood of accidents. Investing in danger tape is not just a regulatory requirement but a commitment to creating a safer environment for everyone involved.