Understanding Container Liners: Essential Solutions for Bulk Transport

Container liners are an indispensable solution for the safe transport of bulk materials across various industries. Their moisture-resistant properties, durability, and customizable options make them a preferred choice for companies looking to protect their products during shipping. As the demand for efficient and reliable packaging solutions grows, the role of container liners manufacturers becomes increasingly important. By understanding the benefits and applications of container liners, businesses can make informed decisions that enhance their logistics strategies and ensure the safe delivery of their goods. With the right liner bag container, companies can significantly reduce the risks associated with bulk transport, ultimately leading to improved operational efficiency and customer satisfaction.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Container liners have become an essential component in the shipping and logistics industry, particularly for transporting bulk materials. These liners provide a protective barrier for the contents of shipping containers, ensuring that products remain safe from contamination, moisture, and other environmental factors. This article explores the features, applications, and advantages of container liners, while also highlighting the role of container liners manufacturers in producing these vital packaging solutions.

What are Container Liners?

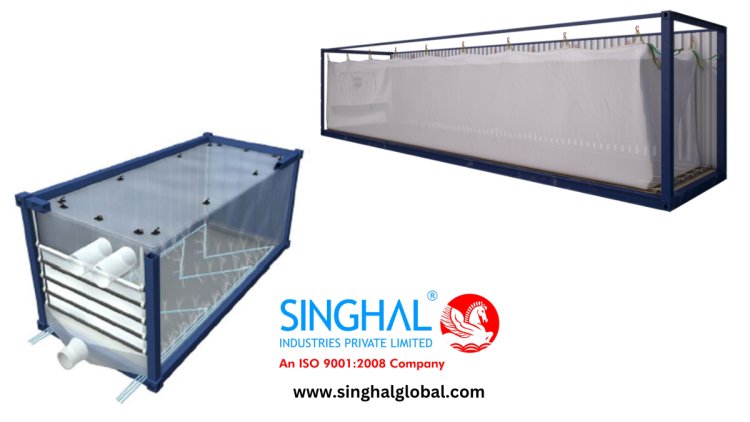

Container liners, also known as Liner bag containers, are flexible bags or liners made from various materials, such as polyethylene or polypropylene. They are designed to fit inside shipping containers, providing a protective layer that helps secure bulk materials during transportation. Container liners can be tailored to fit standard container sizes, making them versatile for various shipping needs.

Key Features of Container Liners

-

Moisture Resistance: Container liners are typically designed to be moisture-resistant, which is crucial for protecting products from humidity and condensation during transit.

-

Durability: Made from strong materials, container liners can withstand the rigors of shipping and handling, reducing the risk of tears or leaks.

-

Easy Installation: These liners can be easily installed in containers, allowing for quick loading and unloading of bulk materials.

-

Customizable Options: Many manufacturers offer customization in terms of size, thickness, and material, allowing businesses to choose the right liner for their specific needs.

Applications of Container Liners

1. Agriculture

Container liners are extensively used in the agricultural sector for transporting grains, seeds, and fertilizers. The moisture-resistant properties help keep agricultural products fresh and free from pests during shipping.

2. Chemicals

In the chemical industry, container liners are used to transport various bulk chemicals safely. The liners prevent contamination and leaks, ensuring that hazardous materials are securely contained.

3. Food Industry

Container liners are ideal for transporting bulk food items, such as sugar, flour, and rice. They help maintain the quality of the food by providing a barrier against moisture and contaminants.

4. Construction Materials

Container liners are also used in the construction sector for transporting sand, gravel, and other bulk materials. The durable construction of the liners ensures that the contents remain secure during transit.

Advantages of Using Container Liners

1. Enhanced Protection

Container liners provide a protective barrier for bulk materials, reducing the risk of contamination, moisture damage, and spillage. This is particularly important for industries that handle sensitive products, such as food and chemicals.

2. Cost-Effective Solution

Using container liners can lead to cost savings by minimizing product loss and damage during transportation. This efficiency can significantly impact a company’s bottom line, especially when shipping large quantities of goods.

3. Space Efficiency

Container liners maximize the use of container space, allowing for efficient loading and unloading of bulk materials. Their design enables optimal packing, which can lead to reduced shipping costs.

4. Environmentally Friendly Options

Many container liners are made from recyclable materials, contributing to sustainable practices in shipping and logistics. By choosing eco-friendly liners, businesses can reduce their environmental footprint.

The Role of Container Liners Manufacturers

Container liners manufacturers play a critical role in producing high-quality liners that meet industry standards. They utilize advanced manufacturing processes and materials to ensure that liners are durable, moisture-resistant, and suitable for various applications.

Choosing the Right Container Liners Manufacturer

When selecting a container liners manufacturer, businesses should consider the following factors:

-

Quality Standards: Look for manufacturers that adhere to quality certifications and industry standards to ensure product reliability.

-

Customization Capabilities: A good manufacturer should offer a range of customization options to meet specific packaging needs.

-

Production Capacity: Ensure the manufacturer can meet your volume requirements within your desired timeline.

-

Reputation and Experience: Research the manufacturer’s reputation in the industry, including customer reviews and feedback.

FAQs

1. What materials are container liners made from?

Container liners are typically made from materials such as polyethylene and polypropylene, which offer moisture resistance and durability. The choice of material can depend on the specific requirements of the products being shipped.

2. Are container liners suitable for food products?

Yes, many container liners are specifically designed for food applications and are made from food-safe materials. They help maintain the quality and safety of bulk food items during transport.

3. How do I install a container liner in a shipping container?

Installing a container liner is straightforward. The liner is placed inside the container and secured at the top. The process can typically be completed quickly, allowing for efficient loading of bulk materials.

4. Can container liners be recycled?

Yes, many container liners are made from recyclable materials. Businesses should check with their liners manufacturer for specific recycling guidelines and options.