Understanding Conical Bags: A Versatile Packaging Solution

Conical bags offer a versatile and efficient packaging solution that meets the needs of various industries, including agriculture, food, and retail. Their unique design enhances storage, ease of filling, and durability, making them a preferred choice for many applications. As the demand for conical bags continues to grow in India, partnering with reputable conical bag manufacturers and suppliers can help businesses streamline their packaging processes and improve product presentation. By choosing the right supplier and material, companies can leverage the benefits of conical bags to enhance their operations and better serve their customers.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Conical bags are an innovative and practical packaging solution widely used in various industries, including food, agriculture, and retail. Their unique shape and design provide numerous advantages, making them a preferred choice for packaging products that require stability and ease of handling. In India, the demand for conical bags has surged, driven by their versatility and the growing need for efficient packaging solutions.

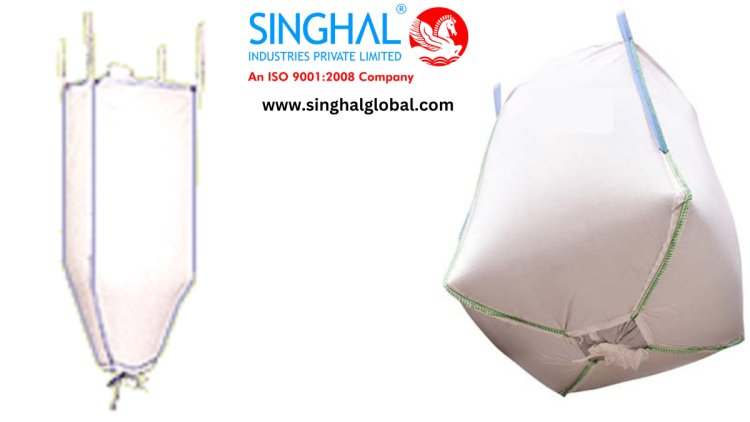

What Are Conical Bags?

Conical bags in India are characterized by their tapered shape, resembling a cone. This design allows for optimal stacking and storage, making them suitable for both bulk and retail packaging. They are typically made from materials like polyethylene, polypropylene, or paper, which can be chosen based on the intended use and required durability.

Key Features of Conical Bags

-

Space Efficiency: The conical shape enables efficient use of space during storage and transportation. These bags can be stacked neatly, minimizing the required storage area and reducing shipping costs.

-

Ease of Filling: The wide opening at the top of conical bags makes them easy to fill, whether with loose items, granules, or liquids. This feature is particularly beneficial in industrial and agricultural applications where time and efficiency are crucial.

-

Durability: Depending on the material used, conical bags can offer excellent strength and resistance to moisture, making them suitable for various products, including food grains, seeds, and chemicals.

-

Customizable: Conical bags can be tailored to meet specific requirements, including size, material, and printing options. This customization helps businesses create packaging that aligns with their branding and product needs.

Applications of Conical Bags

Conical bags are employed in a diverse range of applications:

-

Agriculture: They are widely used for packaging seeds, fertilizers, and grains. The conical design allows for easy pouring and reduces spillage during transport.

-

Food Industry: In the food sector, conical bags are utilized for packaging snacks, nuts, and other bulk food items. Their moisture resistance helps keep products fresh and safe.

-

Retail: Many retailers use conical bags for product displays, offering customers a unique and eye-catching way to package items.

-

Industrial Use: Conical bags are also found in various industrial applications, including packaging chemicals and powders, due to their robust nature.

Conical Bag Manufacturers and Suppliers in India

The rise in demand for conical bags has led to a growing number of Conical bag manufacturers in India. These manufacturers provide a wide range of conical bags tailored to different industries and applications. As businesses seek reliable packaging solutions, partnering with a reputable Conical bag supplier can significantly enhance product presentation and handling.

Choosing the Right Supplier

When selecting a conical bag supplier, consider the following factors:

-

Quality Assurance: Ensure that the manufacturer adheres to industry standards and produces high-quality bags that meet your specifications.

-

Customization Options: Look for suppliers that offer customization in terms of size, material, and printing to help your products stand out in the market.

-

Sustainability Practices: Opt for manufacturers who prioritize eco-friendly materials and sustainable production processes, contributing to environmental conservation.

-

Timely Delivery: A reliable supplier should be able to deliver products on time, helping you maintain your production schedule without interruptions.

FAQs

1. What materials are used to make conical bags?

Conical bags can be made from various materials, including polyethylene, polypropylene, and paper. The choice of material depends on the specific application and required durability.

2. Can conical bags be customized?

Yes, conical bags can be customized in terms of size, material, and printing options. This allows businesses to create packaging that aligns with their branding and product requirements.

3. Are conical bags suitable for food packaging?

Absolutely! Conical bags are widely used in the food industry for packaging items such as snacks and bulk foods due to their moisture resistance and ease of handling.

4. How do I choose a reliable conical bag supplier?

When selecting a supplier, consider factors such as product quality, customization options, sustainability practices, and the ability to meet delivery timelines to ensure you find the right fit for your needs.