Understanding Biaxial Geogrids: Key Insights from Manufacturers in Ahmedabad and Gujarat

Biaxial geogrids are essential for modern construction and infrastructure projects, offering enhanced soil stabilization, load distribution, and durability. With the growing demand for high-quality geogrids, biaxial geogrid manufacturers in Ahmedabad and biaxial geogrid manufacturers in Gujarat have become key players in both the domestic and international markets. These manufacturers produce superior products that meet global standards, with numerous applications in road construction, retaining walls, railways, and more. As the industry continues to expand, biaxial geogrid exporters in Ahmedabad play a vital role in meeting the needs of clients worldwide, ensuring sustainable and cost-effective solutions for a range of engineering challenges.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Biaxial geogrids have gained substantial recognition in the construction and infrastructure sectors due to their exceptional strength and durability. These geosynthetic materials, designed to reinforce soil, stabilize base layers, and improve overall ground performance, have become an essential component for modern construction projects. The demand for high-quality biaxial geogrids has given rise to numerous specialized manufacturers across India, particularly in regions like Ahmedabad and Gujarat. In this article, we explore the role of biaxial geogrids, their applications, and how manufacturers and exporters from Ahmedabad and Gujarat are contributing to the global market.

What is a Biaxial Geogrid?

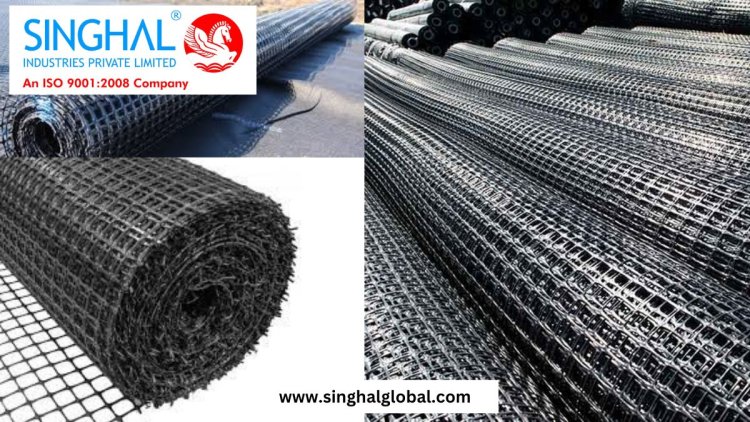

A biaxial geogrid is a polymeric material used primarily in soil reinforcement. Unlike uniaxial geogrids, which have strength in only one direction, biaxial geogrids provide strength in two directions. This unique feature makes them highly effective for applications that require stability and resistance to soil movement in multiple directions, such as roadways, embankments, retaining walls, and other infrastructure projects.

These geogrids are typically made from high-density polyethylene (HDPE) or polypropylene (PP), both of which are known for their durability and resistance to harsh environmental conditions. The design and structure of a biaxial geogrid consist of intersecting ribs or strands that create a grid pattern, which enhances the mechanical interlocking with the surrounding soil, ultimately improving the overall strength and load distribution.

Applications of Biaxial Geogrids

Biaxial geogrids are widely used across various sectors due to their versatile properties. Some common applications include:

-

Road Construction: Biaxial geogrids are widely used in roadbase reinforcement. They help to distribute loads evenly across the foundation, enhancing the strength and longevity of roads, especially in areas with weak subsoil.

-

Retaining Walls: The use of biaxial geogrids in retaining wall systems provides additional support and stability, preventing soil movement and maintaining the integrity of the structure.

-

Landfills and Waste Management: In landfill construction, these geogrids help to stabilize the soil, reduce settlement, and support the overall structure of the landfill.

-

Railway Track Reinforcement: Biaxial geogrids are employed under railway tracks to enhance the soil's load-bearing capacity, ensuring stability and preventing the deformation of the tracks over time.

-

Slope Protection: These geogrids are also used for reinforcing slopes and embankments, preventing soil erosion and reducing the risk of landslides or other soil-related hazards.

The Role of Biaxial Geogrid Manufacturers in Ahmedabad and Gujarat

India has emerged as a major hub for the production and export of geosynthetic materials, and the cities of Ahmedabad and Gujarat are at the forefront of this industry. The presence of experienced biaxial geogrid manufacturers in Ahmedabad and Biaxial geogrid manufacturers in Gujarat has enabled the country to meet the growing demand for high-quality geosynthetics, both domestically and internationally.

Biaxial geogrid manufacturers in Ahmedabad and Gujarat employ cutting-edge technology and production methods to ensure that their products meet international standards. The emphasis is placed on quality control, material selection, and the performance of the final product in real-world applications. These manufacturers often use advanced extrusion processes to produce biaxial geogrids with uniform thickness, high tensile strength, and excellent resistance to environmental factors like UV radiation and chemical exposure.

Additionally, many of these manufacturers have expanded their reach globally, with biaxial geogrid exporters from Ahmedabad playing a pivotal role in supplying high-quality geogrids to countries around the world. Exporting is a key facet of the industry, as international demand for sustainable and reliable infrastructure solutions continues to rise.

Advantages of Biaxial Geogrids

Biaxial geogrids offer a multitude of benefits, making them an attractive solution for a wide range of engineering and construction projects:

-

Enhanced Load Distribution: By providing reinforcement in two directions, biaxial geogrids distribute loads more efficiently across the ground, reducing the risk of soil failure and structural damage.

-

Improved Soil Stabilization: The ability of biaxial geogrids to interlock with surrounding soil improves soil stability, which is especially crucial for applications in weak or loose soil conditions.

-

Cost-Effective: Biaxial geogrids help reduce the overall material requirements for construction projects, leading to lower costs while maintaining high performance and durability.

-

Environmental Sustainability: Geogrids made from polymeric materials are typically resistant to environmental degradation, ensuring a long service life. Their ability to reduce the amount of raw materials required in construction projects also contributes to more sustainable infrastructure development.

-

Versatility: These geogrids can be used in a wide range of applications, from roads and railways to slope protection and landfill stabilization.

Why Choose Biaxial Geogrid Manufacturers in Ahmedabad and Gujarat?

Choosing a reliable and experienced manufacturer is crucial for obtaining high-quality biaxial geogrids. The Biaxial geogrid manufacturers in Ahmedabad and biaxial geogrid manufacturers in Gujarat offer several advantages, including:

- Quality Assurance: These manufacturers follow strict quality control processes to ensure that the products meet industry standards.

- Advanced Technology: Many manufacturers utilize modern production techniques and equipment to produce geogrids with enhanced properties.

- Competitive Pricing: Manufacturers in Ahmedabad and Gujarat often offer cost-effective solutions without compromising on quality, making them an attractive choice for both domestic and international clients.

- Export Capabilities: As leading Biaxial geogrid exporters in Ahmedabad, many companies have extensive experience in meeting the global demand for geosynthetic products.

FAQs

1. What is the difference between biaxial and uniaxial geogrids?

Biaxial geogrids provide strength in both horizontal and vertical directions, whereas uniaxial geogrids only offer strength in one direction. This makes biaxial geogrids more suitable for applications that require multi-directional soil reinforcement.

2. How long do biaxial geogrids last?

Biaxial geogrids are highly durable and can last for several decades, depending on environmental conditions. Their resistance to UV radiation, chemicals, and mechanical stress ensures a long service life, making them a cost-effective solution for infrastructure projects.

3. Can biaxial geogrids be used in all soil conditions?

Yes, biaxial geogrids can be used in various soil conditions, including weak, loose, or unstable soils. Their ability to interlock with soil particles improves stability, making them an ideal solution for challenging ground conditions.