Understanding Biaxial Geogrid: Enhancing Ground Stability and Performance

Biaxial geogrids are invaluable tools in enhancing soil stability and performance across various applications, from road construction to slope stabilization. Their ability to distribute loads, improve soil integrity, and reduce costs makes them a preferred choice for many civil engineering projects. When sourcing these materials, engaging with reputable geogrid manufacturers in India and understanding the biaxial geogrid installation process are essential for maximizing their benefits. By considering the factors discussed, you can ensure successful implementation and improved project outcomes.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

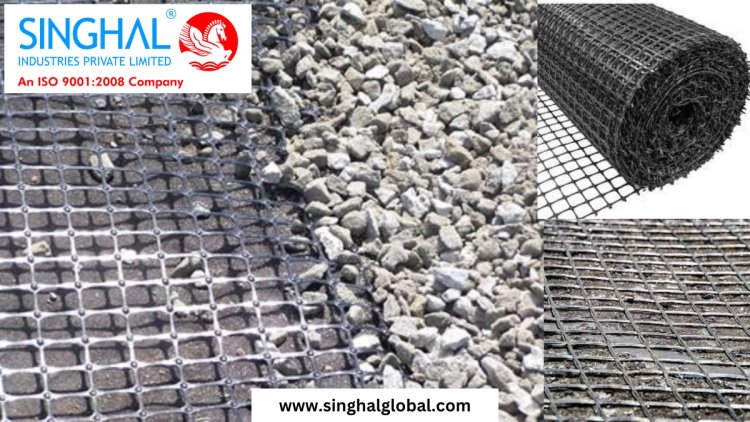

Biaxial geogrids are an essential component in civil engineering and construction, particularly in improving the stability and strength of soil structures. By providing reinforcement to various soil applications, these geogrids significantly enhance the performance of roads, pavements, and retaining structures. This article delves into the characteristics, benefits, and applications of biaxial geogrids, focusing on sourcing options and the role of Geogrid manufacturers in India.

What is Biaxial Geogrid?

Biaxial geogrids are synthetic materials made from polymers, typically high-density polyethylene (HDPE) or polypropylene (PP). These grids are designed with a series of interconnected ribs, which can effectively distribute loads across a broader area. The key feature of biaxial geogrids is their capability to perform in two perpendicular directions, making them suitable for various engineering applications where multidirectional strength is required.

Key Benefits of Biaxial Geogrids

-

Improved Load Distribution: Biaxial geogrids enhance the load-bearing capacity of the soil by distributing applied loads over a larger area. This results in reduced settlement and deformation, leading to more stable structures.

-

Enhanced Soil Stability: By reinforcing the soil, biaxial geogrids help to prevent erosion and instability, particularly in slopes and embankments. This stabilization is crucial in maintaining the integrity of roads and foundations.

-

Cost-Effective Solution: Incorporating biaxial geogrids can reduce the amount of granular fill material required for construction, leading to lower material costs and minimizing excavation work.

-

Environmental Benefits: Using geogrids can help reduce the environmental footprint of construction projects. They can enhance soil performance without requiring additional materials, minimizing disruption to the ecosystem.

-

Long Lifespan: Biaxial geogrids are resistant to degradation from UV radiation and chemical exposure, ensuring a long lifespan and reducing maintenance costs.

Applications of Biaxial Geogrids

1. Road and Pavement Construction

In road construction, biaxial geogrids are used to reinforce subgrade and base layers, improving load distribution and preventing pavement cracking. This is particularly beneficial in areas with heavy traffic loads.

2. Retaining Structures

Biaxial geogrids are commonly employed in the construction of retaining walls and earth structures. They help stabilize the soil behind retaining walls, providing support and preventing soil movement.

3. Slope Stabilization

When applied to slopes, biaxial geogrids can significantly reduce the risk of landslides and erosion. They improve the soil’s shear strength and provide support for vegetation, enhancing natural stabilization.

4. Landfills and Waste Management

Biaxial geogrids are utilized in landfill applications to provide stability to the waste mass, improve drainage, and reduce settlement. This helps maintain the integrity of landfill sites over time.

5. Parking Lots and Industrial Sites

In parking lots and heavy-use industrial sites, biaxial geogrids enhance load capacity, reduce rutting, and prevent surface deformation. Their application is crucial in areas subject to heavy loads from vehicles and machinery.

Biaxial Geogrid Installation

Proper Biaxial geogrid installation is vital for maximizing the benefits of this material. The installation process typically involves the following steps:

-

Site Preparation: Clear the site of debris, vegetation, and any loose soil. The surface should be compacted to ensure a stable base.

-

Layering: Lay the biaxial geogrid over the prepared subgrade. Ensure that it is flat and free from wrinkles or folds.

-

Anchoring: Secure the geogrid in place using stakes, anchors, or by placing granular material over it. Proper anchoring prevents movement during installation.

-

Filling: Cover the geogrid with appropriate fill material. The fill should be evenly distributed and compacted to achieve the desired density.

-

Compaction: Compact the fill material thoroughly to ensure maximum load distribution and stability. This step is crucial for the overall effectiveness of the geogrid.

Sourcing Biaxial Geogrids

When looking for biaxial geogrids, it's essential to consider reputable Geogrid manufacturers and specifically those that operate within the Indian market. Here are some tips for sourcing quality geogrids:

-

Quality Assurance: Choose manufacturers who adhere to international quality standards. Look for certifications that indicate compliance with relevant engineering specifications.

-

Product Range: A reliable manufacturer should offer a variety of geogrid options to suit different applications, including biaxial and uniaxial geogrids.

-

Technical Support: Look for suppliers who provide comprehensive technical support, including installation guidance and project-specific recommendations.

-

Customer Reviews: Research feedback from previous clients to gauge the reliability and quality of the products offered by the manufacturer.

-

Local Availability: Engaging with geogrid manufacturers in India can facilitate easier sourcing, timely delivery, and potential cost savings on transportation.

Frequently Asked Questions (FAQs)

1. What is the difference between biaxial and uniaxial geogrids?

Biaxial geogrids are designed to provide strength and reinforcement in two perpendicular directions, making them suitable for a wide range of applications. In contrast, uniaxial geogrids provide strength primarily in one direction and are often used for applications like retaining walls and slope stabilization.

2. How do I determine the right type of geogrid for my project?

Selecting the appropriate geogrid depends on the specific requirements of your project, such as load conditions, soil type, and application area. Consulting with geogrid manufacturers or engineers can help you make an informed decision.

3. Are there any maintenance requirements for biaxial geogrids?

Once properly installed, biaxial geogrids typically require minimal maintenance. However, regular inspections are recommended to ensure the integrity of the geogrid and the surrounding soil, particularly in areas prone to erosion or heavy traffic.