PC Hollow Sheets: Versatile and Durable Solutions for Modern Construction

PC hollow sheets, also known as polycarbonate hollow sheets, are becoming a popular choice in construction, architecture, and a range of industrial applications. Known for their lightweight structure, high impact resistance, and superior transparency, these sheets offer a practical alternative to glass and other traditional building materials. The hollow structure of these polycarbonate sheets provides excellent thermal insulation, making them energy-efficient and versatile for both residential and commercial use. In this Pulkit Plastic Products, we explore the benefits, applications, and growing demand for PC hollow sheets, particularly in India, where innovative construction materials are increasingly required to meet the demands of modern architecture.

1. What are PC Hollow Sheets?

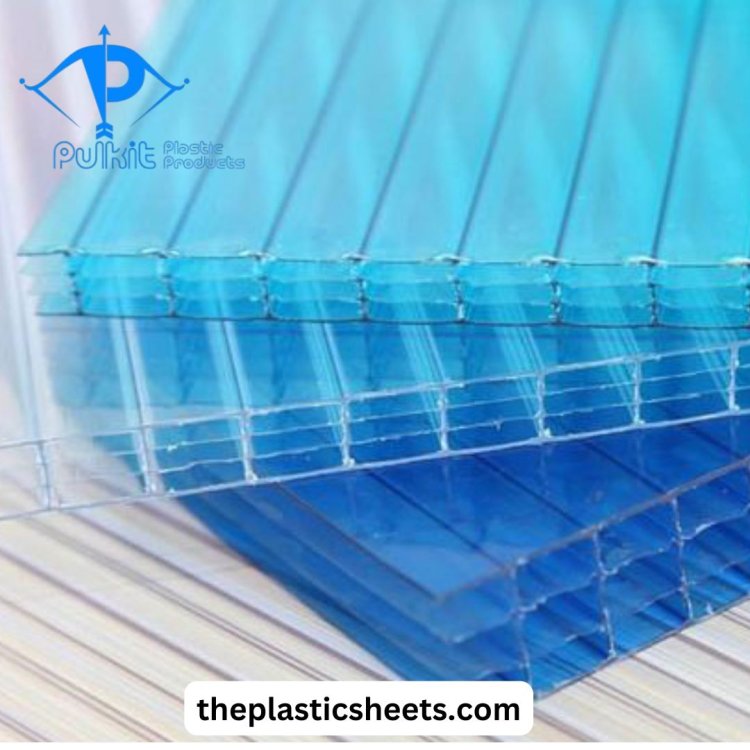

PC hollow sheets, or Hollow Sheet Polycarbonate, are made from polycarbonate, a durable thermoplastic polymer known for its strength, light weight, and transparency. These sheets consist of two or more layers with hollow spaces between them, which give them excellent thermal insulation properties. The unique design of these hollow polycarbonate sheets also reduces their overall weight without compromising on strength, making them easy to handle and install in various construction projects.

Polycarbonate hollow sheets offer several advantages over traditional building materials such as glass or acrylic. Their impact resistance is significantly higher than glass, making them safer in environments prone to breakage. Furthermore, their flexibility and UV resistance make them suitable for outdoor use, as they can withstand harsh weather conditions without yellowing or cracking over time. This combination of features has made hollow sheet polycarbonate a favored material in the construction of greenhouses, skylights, and even indoor partition walls.

2. Manufacturing Process of Polycarbonate Hollow Sheets

The manufacturing process of polycarbonate hollow sheets involves the extrusion of polycarbonate resin into sheet form, which is then molded into the desired structure. The hollow channels are created during this process, which gives the sheet its characteristic light weight and insulating properties. Different thicknesses and designs can be achieved by adjusting the manufacturing process, allowing for a wide range of applications depending on the specific needs of the project.

Many polycarbonate hollow sheet manufacturers are focused on producing high-quality products that meet international standards. These manufacturers often incorporate UV coatings into their sheets, protecting them from the harmful effects of prolonged sun exposure. This coating ensures that the sheets remain clear and durable even after years of outdoor use. In India, the demand for hollow polycarbonate sheets has risen dramatically, as more builders and architects recognize the value of these materials in creating energy-efficient and long-lasting structures.

3. Applications of PC Hollow Sheets in Construction

One of the primary uses of PC hollow sheets is in construction, particularly in areas where transparency, insulation, and impact resistance are required. These sheets are often used to create skylights, canopies, and atriums, providing natural light while also reducing heat transfer. Their ability to block UV rays while allowing sunlight to pass through makes them an excellent choice for structures where lighting and thermal comfort are critical factors.

Greenhouses are another popular application for polycarbonate hollow sheets. Their excellent thermal insulation helps to maintain the internal temperature of the greenhouse, promoting optimal conditions for plant growth. The light diffusion properties of these sheets ensure that plants receive even sunlight, preventing scorching or uneven growth. Additionally, their lightweight nature makes them easy to install and maintain, reducing the overall cost of greenhouse construction.

In addition to these applications, polycarbonate hollow sheets are used for building facades, roofing, and cladding. The combination of strength and flexibility allows architects to create unique designs that are both functional and aesthetically pleasing. Whether used in commercial buildings or residential homes, PC hollow sheets provide a modern, energy-efficient solution that meets the demands of contemporary architecture.

4. Polycarbonate Hollow Sheets vs. Solid Polycarbonate Sheets

While both polycarbonate hollow sheets and solid polycarbonate sheets are made from the same base material, they have distinct differences that make them suitable for different applications. Solid polycarbonate sheets are denser and offer greater impact resistance, which makes them ideal for areas where strength and protection are paramount, such as in security windows, machine guards, and protective barriers.

On the other hand, hollow polycarbonate sheets are more focused on thermal insulation and lightweight properties. Their hollow structure makes them ideal for use in skylights, greenhouses, and areas where energy efficiency is essential. Hollow sheets are also more cost-effective due to their lower material usage while still providing excellent durability and transparency.

Both types of polycarbonate sheets are highly versatile, but the choice between hollow and solid sheets depends on the specific requirements of the project. In many cases, hollow sheet polycarbonate is preferred for its ability to provide natural light and insulation, while solid polycarbonate is favored in applications that require maximum strength and protection.

5. Advantages of Using Hollow Polycarbonate Sheets

There are several reasons why polycarbonate hollow sheets are gaining popularity in modern construction. One of the key advantages is their energy efficiency. The hollow structure of these sheets helps to reduce heat transfer, keeping indoor spaces cooler in hot weather and warmer in cold weather. This thermal insulation can lead to significant energy savings, especially in large buildings or greenhouses that require climate control.

In addition to energy efficiency, polycarbonate hollow sheets are lightweight, making them easier to transport and install compared to heavier materials like glass. Despite their light weight, these sheets are incredibly durable and can withstand impact, making them a safe option for areas where breakage is a concern.

UV resistance is another important feature of hollow polycarbonate sheets. The UV coating applied to the surface of these sheets ensures that they do not degrade or yellow when exposed to sunlight, making them suitable for long-term outdoor use. This durability reduces the need for frequent replacements, further enhancing the cost-effectiveness of these sheets.

6. Challenges in the Use of PC Hollow Sheets

While Polycarbonate Hollow Sheets offer many benefits, there are some challenges associated with their use. One of the primary concerns is the potential for scratching. Polycarbonate, while strong, is more prone to surface scratches compared to materials like glass. However, many manufacturers offer scratch-resistant coatings that help to mitigate this issue.

Another challenge is the initial cost. While polycarbonate hollow sheets are more affordable than glass in the long run due to their durability and energy efficiency, the upfront cost can be higher. For some projects, especially smaller residential ones, the initial investment in polycarbonate sheets may seem prohibitive. However, the long-term savings in energy costs and reduced maintenance often justify the higher initial price.

Lastly, polycarbonate sheets, although UV-resistant, are still susceptible to expansion and contraction due to temperature changes. This means that proper installation techniques must be followed to account for thermal expansion, ensuring that the sheets do not warp or crack over time.

7. The Growing Market for Hollow Polycarbonate Sheets in India

India has witnessed a significant rise in demand for hollow polycarbonate sheets, driven by rapid urbanization and the need for energy-efficient construction materials. Indian manufacturers have responded to this demand by producing high-quality polycarbonate hollow sheets that meet the requirements of both domestic and international markets.

The use of polycarbonate hollow sheets in India extends beyond traditional construction. In addition to being used in commercial buildings and greenhouses, these sheets are also employed in the production of bus shelters, carports, and even advertising billboards. The versatility of polycarbonate hollow sheets, coupled with their affordability and durability, makes them a preferred choice in a wide range of applications.

Indian manufacturers are also investing in research and development to create innovative products that cater to specific market needs. For example, UV-resistant and anti-condensation polycarbonate sheets are being developed to meet the demands of agricultural projects and other specialized industries.

8. Conclusion: The Future of PC Hollow Sheets in Construction

PC hollow sheets are proving to be an invaluable material in the modern construction industry due to their durability, energy efficiency, and versatility. With their ability to provide excellent thermal insulation, impact resistance, and UV protection, these sheets are a cost-effective solution for both residential and commercial projects. As the demand for eco-friendly and sustainable building materials grows, the use of polycarbonate hollow sheets is expected to increase in the coming years.

In India, the rising market for Hollow Polycarbonate sheets reflects the growing trend towards energy-efficient and innovative construction solutions. With advancements in manufacturing technologies and the development of new product variations, polycarbonate hollow sheets will continue to be a key component in modern architecture and design.

Frequently Asked Questions (FAQs)

1. What are the main advantages of polycarbonate hollow sheets?

Polycarbonate hollow sheets offer excellent thermal insulation, impact resistance, UV protection, and light weight. They are cost-effective, durable, and versatile, making them ideal for a wide range of construction applications.

2. How do hollow polycarbonate sheets compare to glass?

Hollow polycarbonate sheets are lighter, stronger, and more impact-resistant than glass. They provide better thermal insulation and are easier to install, making them a safer and more energy-efficient alternative to traditional glass.

3. Can polycarbonate hollow sheets be used outdoors?

Yes, polycarbonate hollow sheets are designed for outdoor use and are UV-resistant, preventing them from yellowing or degrading over time when exposed to sunlight.

4. What applications are polycarbonate hollow sheets best suited for?

These sheets are ideal for applications such as skylights, greenhouses, canopies, roofing, and facades. They are also used in signage, bus shelters, and partition walls, providing both aesthetic and functional benefits.