MVCC Covered Conductor Installation: Best Practices and Guidelines

Electricity is a basic need in our lives. From lighting our homes to powering industries, we depend on electricity every day. But as power travels through lines, there can be many challenges—like safety, power loss, and damage during storms. One solution to these problems is the MVCC (Medium Voltage Covered Conductor). At PRABHA POWER, we believe in offering safe, smart, and strong electrical solutions. In this article, we will explain MVCC covered conductors, how to install them properly, and the best practices to follow.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

What is MVCC (Medium Voltage Covered Conductor)?

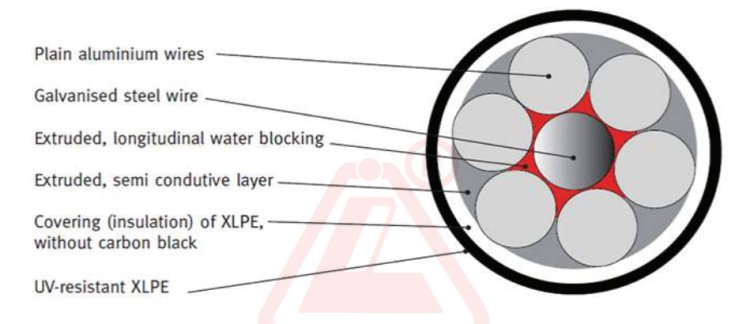

MVCC covered conductor is a type of power line used to carry electricity. Unlike bare conductors that have no cover, MVCC covered conductor has a special insulation layer that covers the metal wire inside. This cover helps in many ways:

-

Reduces chances of short circuits

-

Improves safety

-

Prevents damage from tree branches or birds

-

Works well in harsh weather conditions

MVCC is widely used in medium voltage power distribution systems, usually between 11kV and 33kV.

Why Choose MVCC Conductors?

At PRABHA POWER, we recommend MVCC conductors because they:

1. Improve Safety

MVCC conductors reduce the risk of accidental contact and electrical shock. The covering acts like a shield.

2. Lower Power Loss

Covered conductors help reduce power leakage into the air or ground, improving system efficiency.

3. Withstand Harsh Conditions

These conductors can survive heavy wind, rain, trees touching them, and even animal contact.

4. Cost Effective in Long Term

Although MVCC costs more than bare conductors at the start, it saves money over time by reducing repairs, outages, and maintenance.

Best Practices for MVCC Installation

Installing MVCC is not the same as installing bare conductors. Here are the best practices to follow:

1. Pre-Installation Planning

Before installing MVCC, proper planning is necessary.

✔ Survey the Route

Walk through the entire path where the conductor will be installed. Look for trees, buildings, or other obstructions.

✔ Check Pole Strength

Make sure the poles and crossarms can support the weight and tension of MVCC. These conductors are slightly heavier than bare ones.

✔ Calculate Sag and Tension

MVCC needs proper tension to avoid sagging too much or becoming too tight. Use software or tables to find the correct sag for the distance between poles.

✔ Safety First

Create a safety plan. Everyone on the team should know safety rules. Always wear helmets, gloves, and safety belts while working at height.

2. Use Proper Tools and Equipment

Use the right equipment designed for MVCC installation:

-

Rollers and Stringing Blocks: Prevent damage while pulling the conductor.

-

Tensioners and Pullers: Maintain the correct pulling force to avoid stretching the conductor.

-

Insulated Hand Tools: For handling energized lines safely.

-

Anti-Twisting Devices: To avoid conductor twisting during stringing.

3. Conductor Stringing Guidelines

Follow these steps to string MVCC conductors:

✔ Lay Out the Conductor Properly

Place conductor drums on reel stands. Make sure the conductor comes out smoothly and doesn’t rub against rough surfaces.

✔ Use Stringing Blocks

Install stringing blocks at every pole to guide the conductor. Blocks should be smooth and free from dirt or sharp edges.

✔ Maintain Tension

Do not let the conductor sag or stretch. Follow sag-tension charts.

✔ Avoid Damaging the Cover

Do not drag conductors on the ground or sharp edges. Damaged insulation can lead to failure.

✔ Control the Pulling Speed

Pull slowly and steadily. Fast pulling can lead to snags or cover damage.

4. Fitting Accessories Carefully

You will need fittings like:

-

Insulators

-

Dead-end clamps

-

Suspension clamps

-

Mid-span joints

These must be designed for MVCC. Always follow the manufacturer’s instructions.

✔ Clean Before Use

Wipe the conductor before fitting accessories to remove dust or oil.

✔ Do Not Over-Tighten

Excess force can crush or damage the insulation.

5. Termination and Jointing

Terminating and joining MVCC needs extra care.

✔ Use Heat Shrink or Cold Shrink Kits

These are used to insulate the joints and ends.

✔ Strip the Conductor Carefully

Use special tools to remove insulation without cutting into the metal wire.

✔ Check for Tight Connections

Loose joints can cause overheating and failures.

6. Testing and Inspection

After installation, test the system before energizing.

✔ Visual Inspection

Look for physical damage, cracks, or loose fittings.

✔ Insulation Resistance Test

Use a megger to test the insulation level. This confirms that the covering is still good.

✔ Continuity Check

Ensure there’s a proper connection from start to end.

Installation Mistakes to Avoid

Even small mistakes during installation can lead to big problems. Here are some common errors and how to avoid them:

| Mistake | Problem | Solution |

|---|---|---|

| Pulling too fast | Damages insulation | Pull at a slow and steady speed |

| Using wrong clamps | Cuts the insulation | Use only MVCC-rated clamps |

| Improper sag | Causes snapping or too much sag | Use correct sag-tension chart |

| No testing | Unknown faults | Always test before energizing |

| Sharp tools | Tear the cover | Use insulation-safe tools |

Maintenance Tips for MVCC Systems

Even after installation, MVCC systems need regular care.

✔ Inspect Poles and Hardware

Look for rust, cracks, or loose fittings.

✔ Trim Nearby Trees

Keep tree branches away from the lines.

✔ Thermal Scanning

Use thermal cameras to find hot spots that may indicate a weak connection.

✔ Periodic Testing

Test insulation and continuity once every few years.

✔ Replace Damaged Sections

If insulation is torn, replace the section instead of repairing.

MVCC Installation in Different Terrains

India has many types of land—from flat plains to hilly areas. At PRABHA POWER, we understand that installation must change with the landscape.

✔ Urban Areas

In cities, space is limited. MVCC allows safe power distribution near buildings or crowded spaces.

✔ Forest Areas

MVCC is great for forest zones because tree branches may touch the wires. The insulation prevents faults.

✔ Hilly Areas

In hills, strong winds and uneven pole heights make MVCC a better choice than bare wires.

Environmental Benefits of MVCC

MVCC also helps the environment:

-

Fewer Power Cuts = Less Use of Diesel Generators

-

No Sparks = Less Risk of Forest Fires

-

Long Life = Less Waste

At PRABHA POWER, we believe in green energy solutions, and MVCC is a step in the right direction.

Why PRABHA POWER for MVCC Projects?

We at PRABHA POWER offer high-quality MVCC conductors and installation services across India. Here’s why clients trust us:

✅ Quality Materials

We only use certified and high-grade materials for all conductors and fittings.

✅ Skilled Technicians

Our trained team understands how to safely and correctly install MVCC.

✅ Project Support

From planning to testing, we provide full support throughout your project.

✅ Timely Delivery

We meet deadlines without compromising on quality.

✅ Safety Focus

Our first priority is safety—for our workers, your team, and your community.

Conclusion

MVCC covered conductors are a smart, safe, and efficient way to distribute electricity. They help prevent faults, save energy, and protect lives. But to get the full benefits, it’s important to follow best practices during installation.

At PRABHA POWER, we are here to guide you every step of the way—from choosing the right conductor to successful installation. Whether your project is small or large, urban or rural, we ensure strong performance and reliable power delivery.

Ready to make the switch to MVCC?

Contact PRABHA POWER today for expert advice and dependable service.

umarkhan

umarkhan