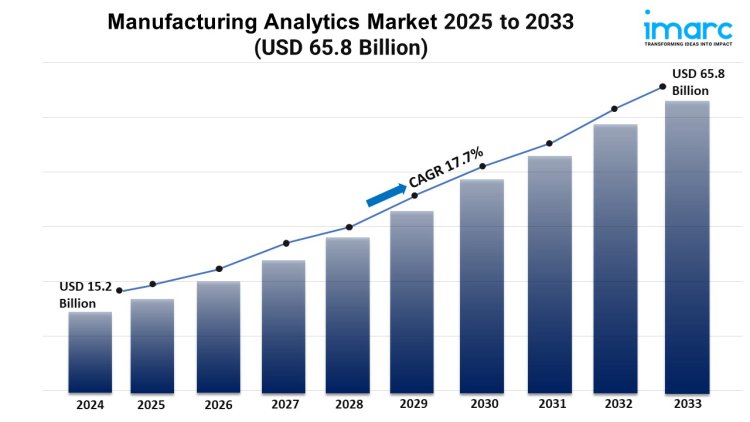

Manufacturing Analytics Market Size, Growth, and Forecast 2025-2033

The global manufacturing analytics market size reached USD 15.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 65.8 Billion by 2033, exhibiting a growth rate (CAGR) of 17.7% during 2025-2033.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Market Overview:

The manufacturing analytics market is experiencing rapid growth, driven by adoption of industry 4.0 technologie, demand for operational efficiency, and regulatory compliance and quality control. According to IMARC Group's latest research publication, "Manufacturing Analytics Market Report by Component (Software, Services), Deployment Model (Cloud-based, On-premises), Application (Predictive Maintenance, Inventory Management, Supply Chain Optimization, and Others), Industry Vertical (Semiconductor and Electronics, Energy and Power, Pharmaceutical, Automobile, Heavy Metal and Machine Manufacturing, and Others), and Region 2025-2033". The global manufacturing analytics market size reached USD 15.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 65.8 Billion by 2033, exhibiting a growth rate (CAGR) of 17.7% during 2025-2033.

Growth Factors in the Manufacturing Analytics Market

- Adoption of Industry 4.0 Technologies:

The rise of Industry 4.0, characterized by the integration of smart technologies like IoT, AI, and machine learning, is a major growth factor for the manufacturing analytics market. Manufacturers are leveraging these technologies to collect real-time data from production lines, enabling predictive maintenance and optimized operations. For example, General Electric implemented IoT-based analytics in its jet engine manufacturing, reducing downtime by predicting maintenance needs. This shift toward interconnected systems allows companies to improve efficiency, reduce costs, and enhance product quality, driving demand for analytics solutions that can process vast amounts of data and provide actionable insights.

- Demand for Operational Efficiency:

Manufacturers face increasing pressure to maximize efficiency while minimizing waste, fueling the adoption of analytics solutions. Advanced analytics tools help identify bottlenecks, streamline supply chains, and optimize resource utilization. For instance, Toyota uses manufacturing analytics to monitor production processes, reducing defects and improving just-in-time inventory management. By analyzing data from equipment, labor, and materials, companies can make data-driven decisions to enhance productivity. This focus on efficiency is particularly critical in industries like automotive and electronics, where competition is fierce, and margins are tight, making analytics a vital tool for staying competitive in a global market.

- Regulatory Compliance and Quality Control:

Stringent regulations and the need for consistent product quality are pushing manufacturers to adopt analytics for compliance and quality assurance. Analytics platforms enable real-time monitoring of production processes to ensure adherence to standards like ISO or FDA regulations. For example, pharmaceutical companies like Pfizer use analytics to track production variables, ensuring drug quality and regulatory compliance. These tools help detect anomalies, reduce defects, and maintain audit trails, minimizing the risk of costly recalls or penalties. As regulatory requirements grow more complex, the demand for analytics solutions that ensure compliance while maintaining high standards continues to rise.

Key Trends in the Manufacturing Analytics Market

- Rise of Predictive and Prescriptive Analytics:

Predictive and prescriptive analytics are transforming manufacturing by enabling proactive decision-making. Predictive analytics forecasts potential equipment failures or supply chain disruptions, while prescriptive analytics suggests optimal responses. For instance, Siemens uses predictive analytics in its gas turbine manufacturing to anticipate maintenance needs, reducing unplanned downtime. Prescriptive analytics goes further by recommending specific actions, such as adjusting production schedules to avoid bottlenecks. These advanced analytics capabilities are becoming essential as manufacturers seek to move beyond reactive strategies, leveraging data to anticipate challenges and optimize processes in real time.

- Integration of Cloud-Based Analytics:

Cloud-based analytics platforms are gaining traction due to their scalability, cost-effectiveness, and accessibility. These solutions allow manufacturers to store and analyze large datasets without investing in expensive on-premises infrastructure. For example, Rockwell Automation’s cloud-based analytics platform helps manufacturers monitor equipment performance across multiple facilities, providing centralized insights. Cloud solutions also enable seamless collaboration among global teams, making them ideal for multinational corporations. As manufacturers prioritize flexibility and remote access, the shift toward cloud-based analytics is accelerating, offering real-time insights and reducing the complexity of managing on-site data systems.

- Emphasis on Sustainability and Green Manufacturing:

Sustainability is a growing trend in manufacturing, with analytics playing a key role in reducing environmental impact. Analytics tools help manufacturers monitor energy consumption, optimize material usage, and minimize waste. For instance, Unilever uses analytics to track energy usage in its production facilities, achieving significant reductions in carbon emissions. By analyzing data from production processes, companies can identify opportunities to adopt eco-friendly practices without compromising efficiency. As consumers and regulators demand greener practices, manufacturers are increasingly turning to analytics to meet sustainability goals, making it a critical trend in the market.

We explore the factors driving the growth of the market, including technological advancements, consumer behaviors, and regulatory changes, along with emerging manufacturing analytics market trends.

Leading Companies Operating in the Global Manufacturing Analytics Industry:

- Alteryx Inc.

- General Electric

- International Business Machines Corporation

- Oracle Corporation

- SAP SE

- SAS Institute Inc.

- Sisense Inc.

- Tableau Software LLC (Salesforce.com Inc.)

- TIBCO Software Inc.

- Wipro Limited

- Zensar Technologies Ltd

Manufacturing Analytics Market Report Segmentation:

Breakup By Component:

- Software

- Services

Software account for the majority of shares as it can optimize operations and enhance product quality.

Breakup By Deployment Model:

- Cloud-based

- On-premises

On-premises dominate the market, which can be attributed to the increasing focus on data security.

Breakup By Application:

- Predictive Maintenance

- Inventory Management

- Supply Chain Optimization

- Others

Predictive maintenance represents the majority of shares due to its ability to avoid costly unplanned downtime by identifying potential equipment failures before they occur.

Breakup By Industry Vertical:

- Semiconductor and Electronics

- Energy and Power

- Pharmaceutical

- Automobile

- Heavy Metal and Machine Manufacturing

- Others

Automobile exhibits a clear dominance on account of the rising adoption of industry 4.0 technologies.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys the leading position owing to a large market for manufacturing analytics driven by the presence of a highly developed manufacturing sector.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145