HDPE T-Rib Liner Sheets: The Ultimate Solution for Durable and Reliable Protection

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

In industrial applications, the need for robust and reliable protective solutions is paramount. HDPE T-Rib Liner Sheets have emerged as a popular choice for businesses looking to safeguard their facilities from corrosion, chemical exposure, and other environmental challenges. This Mahira Polyglobal LLP explores what HDPE T-Rib Liner Sheets are, their key benefits, common applications, installation procedures, and answers to frequently asked questions.

What Are HDPE T-Rib Liner Sheets?

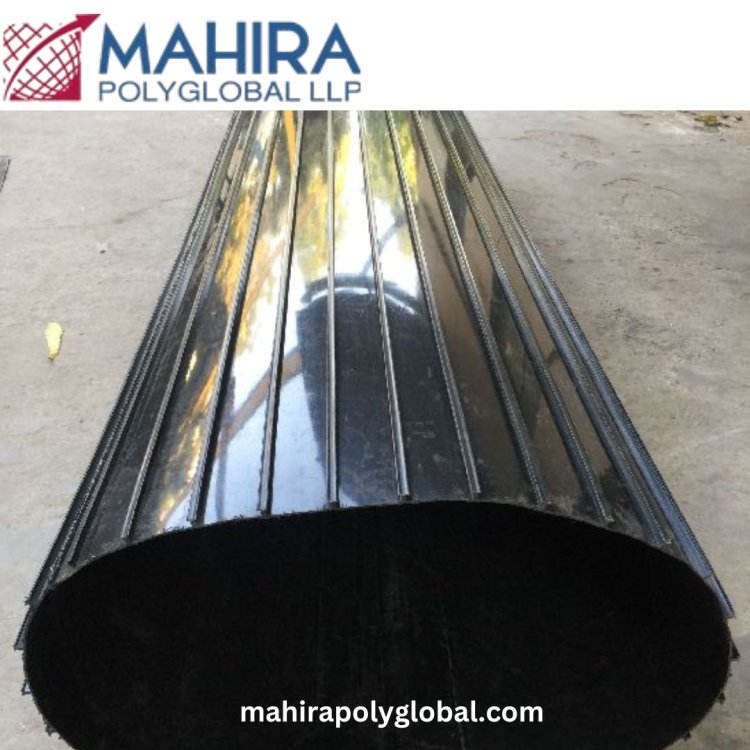

HDPE T Rib Liner Manufacturer are made from High-Density Polyethylene (HDPE), a type of plastic known for its strength, durability, and resistance to various chemicals. The "T-Rib" design refers to the ribbed surface that enhances the liner's strength and structural integrity. These sheets are commonly used as liners in containment applications, such as ponds, landfills, and agricultural settings, to provide effective barriers against leaks and spills.

Key Features of HDPE T-Rib Liner Sheets

-

High Strength: HDPE T-Rib Liner Sheets are engineered to withstand mechanical stresses and heavy loads, making them suitable for demanding environments.

-

Chemical Resistance: The material is resistant to a wide range of chemicals, including acids, bases, and solvents, ensuring that it maintains its integrity even in harsh conditions.

-

Low Permeability: These liners exhibit low permeability, which helps prevent the migration of chemicals and pollutants into the surrounding soil and groundwater.

-

UV Resistance: HDPE T-Rib Liner Sheets can be treated to withstand UV radiation, ensuring their longevity even when exposed to sunlight.

-

Ease of Installation: The sheets are lightweight and flexible, allowing for quick and easy installation in various applications.

Benefits of Using HDPE T-Rib Liner Sheets

1. Corrosion Protection

One of the primary benefits of HDPE T-Rib Liner Sheets is their ability to protect against corrosion. Traditional materials, such as metal and concrete, are prone to degradation over time due to exposure to chemicals and environmental factors. In contrast, HDPE's chemical resistance ensures that the liner remains intact, providing long-lasting protection.

2. Cost-Effective

While the initial investment in HDPE T-Rib Liner Sheets may be higher than some alternatives, their durability and longevity lead to significant cost savings over time. Reduced maintenance, fewer replacements, and decreased risk of environmental liabilities contribute to a lower total cost of ownership.

3. Environmental Safety

By preventing leaks and spills, HDPE T-Rib Liner Sheets play a crucial role in environmental protection. They help contain hazardous materials, ensuring that pollutants do not reach the soil and water sources, thereby complying with environmental regulations and promoting sustainability.

4. Versatile Applications

HDPE T-Rib Liner Sheets can be used in a wide range of applications, including:

- Landfills: To contain waste and prevent leachate from contaminating groundwater.

- Agricultural Ponds: To line irrigation ponds and prevent water loss through seepage.

- Mining Operations: To protect against chemical spills and runoff.

- Wastewater Treatment Facilities: To safeguard against corrosive substances in treatment processes.

5. Enhanced Structural Integrity

The ribbed design of these liner sheets adds to their structural strength, allowing them to better withstand pressure and physical stresses. This feature is particularly beneficial in applications where heavy loads or turbulent conditions are present.

Installation of HDPE T-Rib Liner Sheets

Proper installation is crucial for ensuring the effectiveness of HDPE T-Rib Sheet Suppliers. Here’s a step-by-step guide to the installation process:

1. Site Preparation

- Clear the installation area of any debris, rocks, or sharp objects that could puncture the liner.

- Level the ground to create a smooth surface for the liner installation.

2. Cutting the Liner

- Measure the area where the liner will be installed and cut the HDPE T-Rib Liner Sheets accordingly. Leave extra material to account for overlaps and seams.

3. Placing the Liner

- Lay the liner sheets in the designated area, ensuring that they fit snugly together. The ribbed sides should face upward to enhance strength and prevent slipping.

4. Securing the Liner

- Use appropriate fastening methods to secure the liner in place. This may include using stakes, clips, or welding the seams together, depending on the specific application and site requirements.

5. Backfilling and Covering

- If the liner is being used in a containment application, backfill the area with soil or other materials as required. Ensure that the liner remains taut and does not shift during this process.

6. Final Inspection

- Conduct a thorough inspection of the installed liner to check for any gaps or weaknesses. Address any issues before putting the liner into service.

Conclusion

The T-Rib HDPE Liner Sheets represent a versatile and effective solution for protecting against corrosion and chemical exposure across various industries. With their numerous advantages, including durability, cost-effectiveness, and environmental safety, these liners are an essential component of modern industrial applications. By understanding their features and benefits, businesses can make informed decisions that enhance operational efficiency while safeguarding the environment. Investing in HDPE T-Rib Liner Sheets is not just a practical choice; it’s a commitment to quality and sustainability for the future.

Frequently Asked Questions (FAQs)

1. What makes HDPE T-Rib Liner Sheets different from other liners?

HDPE T-Rib Liner Sheets offer superior chemical resistance, strength, and low permeability compared to traditional liners. Their ribbed design enhances structural integrity, making them suitable for demanding applications.

2. Can HDPE T-Rib Liner Sheets be recycled?

Yes, HDPE is a recyclable material. Many facilities have programs in place to recycle HDPE T-Rib Liner Sheets, contributing to sustainability efforts.

3. What industries commonly use HDPE T-Rib Liner Sheets?

These liner sheets are commonly used in industries such as waste management, agriculture, mining, and wastewater treatment, where protection against leaks and chemical exposure is critical.

4. How long do HDPE T-Rib Liner Sheets last?

With proper installation and maintenance, HDPE T-Rib Liner Sheets can last for several decades. Their resistance to corrosion and UV degradation contributes to their long lifespan.