From Tunnels to Sewage Plants: Versatile Uses of HDPE T-Rib Liner Sheets

High-Density Polyethylene (HDPE) T-Rib liner sheets are increasingly becoming the material of choice for industries needing a durable, corrosion-resistant lining solution for concrete structures. Whether for use in wastewater treatment plants, tunnels, landfills, or storage tanks, these sheets provide a protective layer that prevents chemical attack, moisture infiltration, and corrosion, significantly extending the lifespan of structures and minimizing maintenance costs.

In this article, we will explore what Mahira Polyglobal LLP are, their key benefits, applications, and common questions about their use in various industries.

What Are HDPE T-Rib Liner Sheets?

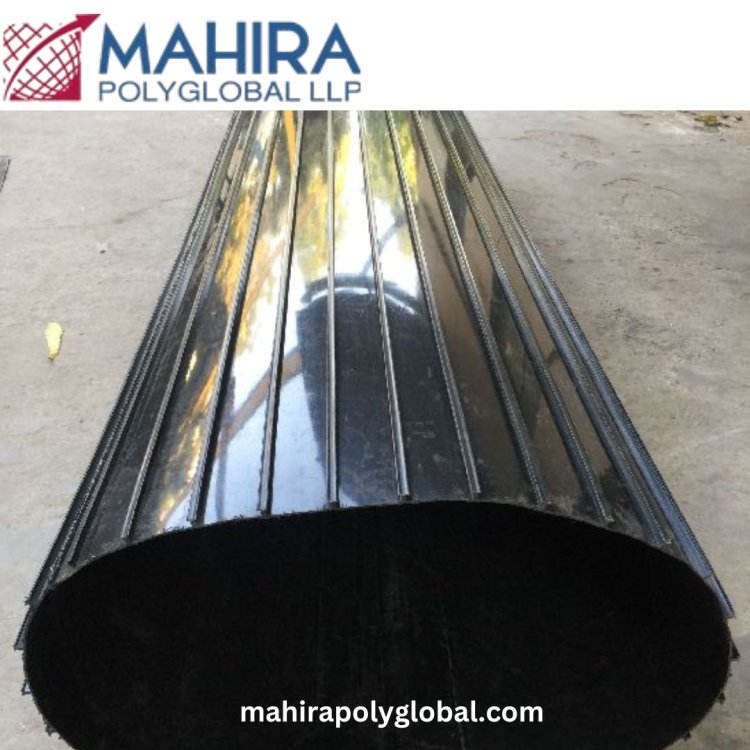

The T-Rib HDPE Liner Sheets India are specially designed plastic sheets made from high-density polyethylene. The term "T-Rib" refers to the unique ribbed profile on one side of the sheet. This ribbed structure enhances the sheet's bonding strength when applied to concrete surfaces, ensuring a secure and long-lasting attachment. The smooth side of the sheet faces outward, providing a non-reactive, non-corrosive surface that resists chemicals, moisture, and other environmental factors.

These sheets are highly valued for their flexibility, strength, and resistance to harsh chemicals, making them ideal for lining concrete structures exposed to aggressive environments such as wastewater, industrial chemicals, or acid rain.

Key Benefits of HDPE T-Rib Liner Sheets

-

Excellent Corrosion Resistance

One of the main reasons industries turn to HDPE T-Rib liner sheets is their superior resistance to corrosion. Concrete structures exposed to water, chemicals, and other corrosive elements often suffer from degradation over time. By lining these structures with HDPE T-Rib sheets, you can protect them from chemical attacks, minimizing the risk of leaks, cracks, and eventual failure. This corrosion resistance is especially critical in wastewater treatment plants, chemical storage tanks, and other industrial facilities. -

Leak Prevention

HDPE T-Rib liner sheets create a seamless, impermeable barrier that prevents water, chemicals, and other liquids from seeping into concrete structures. This leak prevention is crucial in applications like tunnels, where water infiltration can weaken the structure over time, and in landfill sites, where it’s important to prevent leachate from contaminating the surrounding soil and water sources. -

Strong Bond with Concrete

The T-Rib design ensures a secure mechanical bond between the liner and the concrete. The ribs become embedded into the concrete during the casting or construction process, providing a durable attachment that won’t peel or separate over time. This strong bond helps protect concrete surfaces from both mechanical and chemical wear, reducing the need for repairs or replacements. -

Long-Term Durability

HDPE T-Rib liner sheets are known for their high durability and resistance to wear and tear. These sheets can withstand extreme temperatures, UV radiation, and mechanical stress, making them ideal for both indoor and outdoor applications. With proper installation and minimal maintenance, HDPE liners can last for decades, offering long-term protection for structures. -

Cost-Effective

While HDPE T-Rib liner sheets may involve an upfront investment, their long-term benefits far outweigh the initial costs. By extending the lifespan of concrete structures and reducing the need for costly repairs and maintenance, they offer significant cost savings over time. Additionally, their ease of installation can minimize labor costs compared to other lining solutions. -

Chemical and UV Resistance

HDPE is naturally resistant to a wide range of chemicals, including acids, alkalis, and salts, making it suitable for use in highly corrosive environments. Furthermore, HDPE is resistant to UV radiation, so it can be used in outdoor applications without degrading over time due to sunlight exposure.

Applications of HDPE T-Rib Liner Sheets

The T-Rib HDPE Liner Sheets are used in a wide range of industries and applications due to their versatility, strength, and resistance to harsh environmental conditions. Some of the most common applications include:

-

Wastewater Treatment Plants

Wastewater treatment plants often use HDPE T-Rib liner sheets to protect concrete structures from chemical attack and corrosion. The aggressive chemicals and gases present in wastewater can quickly degrade untreated concrete. HDPE liners provide a protective barrier that extends the life of these structures and ensures the smooth operation of the facility. -

Tunnels and Underground Structures

In tunnels and other underground structures, water infiltration can pose a significant risk to structural integrity. HDPE T-Rib liner sheets act as a waterproofing membrane, preventing water from seeping into the concrete and causing cracks, leaks, and other issues. Their durability and flexibility make them an excellent choice for lining tunnels, subway stations, and drainage systems. -

Landfills

HDPE T-Rib liner sheets are commonly used in landfills to prevent leachate—a toxic liquid that forms as waste decomposes—from contaminating the surrounding soil and water sources. These sheets provide a leak-proof barrier that helps maintain environmental safety and regulatory compliance. -

Storage Tanks and Chemical Containment

HDPE T-Rib liners are also used in storage tanks and chemical containment areas to prevent corrosion and leaks caused by harsh chemicals. The liners create a protective layer between the stored substances and the tank walls, preventing chemical reactions that could damage the tank or cause leaks. -

Sewage and Drainage Systems

HDPE T-Rib liners are used in sewage and drainage systems to protect against the corrosive effects of sewage gases and chemicals. The liners provide a smooth surface that allows for efficient flow while protecting the underlying concrete from degradation. -

Canals and Water Reservoirs

In water management applications, such as canals and reservoirs, HDPE T-Rib liners help prevent water loss due to seepage and protect concrete structures from erosion. The liners also help maintain water quality by preventing contamination from external sources.

How to Install HDPE T-Rib Liner Sheets

Proper installation is critical to ensuring the effectiveness of HDPE T-Rib liner sheets. Here’s an overview of the installation process:

-

Surface Preparation

Before installing the liner, the concrete surface must be clean, dry, and free from any debris or irregularities that could affect bonding. Any cracks or imperfections in the concrete should be repaired. -

Positioning the Liner

The HDPE T-Rib liner sheets are positioned with the ribbed side facing the concrete. During the concrete pouring process, the ribs become embedded in the concrete, forming a strong mechanical bond. -

Welding the Seams

HDPE liners are welded together using specialized heat welding techniques to create a seamless, impermeable barrier. This ensures that no liquids can penetrate the joints between the sheets, further enhancing the protective properties of the liner. -

Quality Control

After installation, it is essential to inspect the liner for any defects, such as air pockets, incomplete welds, or damage. Quality control checks help ensure that the liner is properly installed and will perform as expected.

Conclusion

The HDPE T-Rib Liner Sheets Installation offer a durable, cost-effective, and environmentally friendly solution for protecting concrete structures from corrosion, chemical attack, and water infiltration. Their unique design provides a strong bond with concrete, ensuring long-lasting protection in a wide range of industries, from wastewater treatment to tunnel construction. By investing in HDPE T-Rib liners, businesses can significantly extend the lifespan of their structures, reduce maintenance costs, and enhance overall operational efficiency. Whether used in landfills, storage tanks, or underground structures, these liners provide an essential barrier against environmental damage, making them a critical component in modern infrastructure protection.

FAQs About HDPE T-Rib Liner Sheets

Q1: What is the lifespan of HDPE T-Rib liner sheets?

HDPE T-Rib liner sheets are known for their durability and long lifespan. When properly installed and maintained, they can last for 50 years or more, making them an excellent long-term investment for protecting concrete structures.

Q2: Can HDPE T-Rib liner sheets be used in high-temperature environments?

Yes, HDPE T-Rib liner sheets can withstand a wide range of temperatures, from extreme cold to high heat. However, for applications involving very high temperatures, it’s important to check the specific temperature resistance of the liner and consult with the manufacturer.

Q3: Are HDPE T-Rib liner sheets resistant to chemicals?

Yes, HDPE is naturally resistant to a wide variety of chemicals, including acids, alkalis, salts, and hydrocarbons. This makes HDPE T-Rib liners ideal for use in chemical storage tanks, wastewater treatment plants, and other environments exposed to aggressive chemicals.

Q4: How are HDPE T-Rib liner sheets installed?

HDPE T-Rib liners are installed by embedding the ribbed side of the liner into fresh concrete. The ribs provide a strong mechanical bond with the concrete, while the smooth side of the liner faces outward to protect the structure. The sheets are welded together to form a seamless, leak-proof barrier.