Exploring HDPE Sheets: The Versatile Solution for Various Applications

In conclusion, HDPE sheets or high-density polyethylene sheets are a highly versatile material used across numerous industries. Their strength, durability, and resistance to chemicals make them an excellent choice for applications ranging from construction to packaging. By understanding the features and benefits of polyethylene high-density sheets, as well as considering the specific needs of your project, you can make informed decisions that enhance the performance and longevity of your products. With their ability to withstand harsh conditions and be easily fabricated, HDPE sheets remain a go-to solution for many professionals seeking reliability and efficiency in their materials.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

High-density polyethylene (HDPE) sheets are among the most widely used materials in various industries, thanks to their exceptional strength, durability, and resistance to chemicals. Known for their versatility, high-density polyethylene sheets can be found in applications ranging from packaging to construction and beyond. In this article, we’ll explore the features, benefits, and applications of polyethylene high-density sheets, as well as provide insights into choosing the right high-density plastic sheet for your needs.

What are HDPE Sheets?

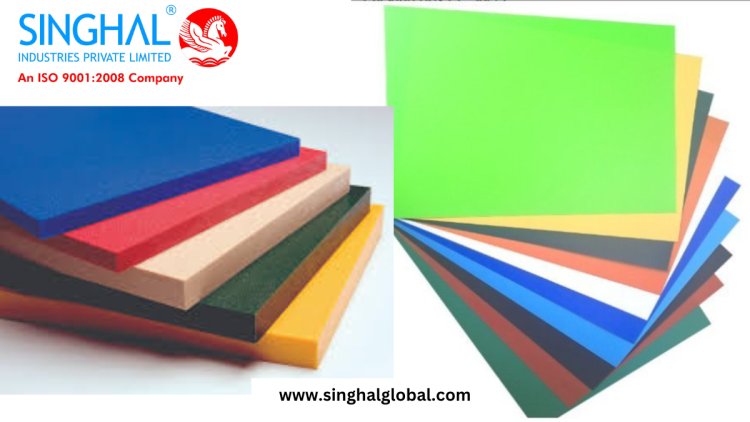

HDPE sheets, or high-density polyethylene sheets, are made from a type of thermoplastic polymer that is characterized by its high strength-to-density ratio. This unique composition makes HDPE sheets lightweight yet incredibly durable, offering excellent resistance to impact, moisture, and chemicals. These sheets are available in various thicknesses, sizes, and colors, making them suitable for a wide range of applications.

Key Features of HDPE Sheets

-

Chemical Resistance: One of the standout features of Polyethylene high-density sheets is their exceptional resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes them ideal for use in laboratories, chemical processing, and waste management.

-

Durability: HDPE sheets are known for their strength and durability. They can withstand extreme temperatures and resist impacts, making them suitable for demanding environments.

-

Lightweight: Despite their robust nature, HDPE sheets are lightweight, which simplifies transportation and installation.

-

Moisture Resistance: The impermeability of HDPE makes it resistant to moisture, preventing warping and degradation, making it ideal for both indoor and outdoor applications.

-

Ease of Fabrication: HDPE sheets can be easily cut, shaped, and welded, allowing for customization to meet specific project requirements.

Applications of HDPE Sheets

The versatility of High-density polyethylene sheets allows them to be utilized in a variety of industries:

1. Construction and Engineering

In the construction sector, HDPE sheets are used for waterproofing, lining, and drainage applications. Their chemical resistance makes them suitable for use in landfills, where they can serve as liners to prevent leachate from contaminating the soil and groundwater.

2. Packaging

High-density plastic sheets are widely used in the packaging industry for their strength and moisture resistance. They can be used to create sturdy containers, pallets, and crates, offering protection for a variety of products during storage and transportation.

3. Agriculture

In agriculture, HDPE sheets are used for greenhouse covers, irrigation systems, and protective liners for ponds and reservoirs. Their durability and resistance to UV radiation make them ideal for outdoor applications.

4. Signage and Displays

The lightweight nature of HDPE sheets, combined with their resistance to fading and weathering, makes them an excellent choice for outdoor signage and displays. They can be printed on, cut into various shapes, and easily installed.

5. Marine Applications

In marine settings, HDPE sheets are often used for docks, boat ramps, and other structures that require resistance to water and chemicals. Their buoyancy and durability make them a preferred material in such environments.

Choosing the Right HDPE Sheet

When selecting a high-density plastic sheet for your project, consider the following factors:

-

Thickness: HDPE sheets come in various thicknesses. Consider the specific requirements of your application to choose the right thickness for strength and durability.

-

Color: HDPE sheets are available in a range of colors. Depending on the application, color may play a role in aesthetics or functionality, such as UV resistance.

-

Finish: Consider whether you need a smooth or textured finish. A textured finish may provide better grip or aesthetic appeal, while a smooth finish may be easier to clean.

-

Size: HDPE sheets are available in different dimensions. Ensure you select a size that fits your project needs and reduces the amount of waste generated during fabrication.

Benefits of Using HDPE Sheets

-

Cost-Effectiveness: Although high-density polyethylene sheets may have a higher initial cost compared to other materials, their durability and long lifespan often lead to lower total costs over time.

-

Sustainability: HDPE is a recyclable material, making it an environmentally friendly choice. Many manufacturers now produce HDPE sheets from recycled materials, further enhancing their sustainability profile.

-

Customizability: The ease of fabrication allows for customization to meet specific project needs, whether it’s cutting sheets to size or creating complex shapes.

FAQs

1. What are the main differences between HDPE sheets and other plastic sheets?

HDPE sheets are known for their high strength, durability, and chemical resistance compared to other plastic sheets like PVC or polypropylene. They offer superior performance in demanding applications and have a higher resistance to moisture and environmental stressors.

2. Can HDPE sheets be used outdoors?

Yes, high-density polyethylene sheets are ideal for outdoor use due to their resistance to UV radiation, moisture, and temperature fluctuations. This makes them suitable for applications such as signage, agricultural covers, and construction liners.

3. How can HDPE sheets be fabricated for specific uses?

Polyethylene high-density sheets can be easily cut, welded, and shaped using standard tools. Common fabrication methods include CNC machining, laser cutting, and heat welding, allowing for precise customization to meet the needs of various applications.