Design Factors of Graphic Overlay: A Full Guide

This comprehensive guide outlines the critical design factors you must consider and explains why partnering with the best graphic overlay manufacturer is essential to get it right.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

A graphic overlay is more than just a decorative top layer—it's the face of your product’s user interface. Whether used on medical devices, industrial machinery, consumer electronics, or membrane switches, a well-designed overlay enhances functionality, branding, and user experience. This comprehensive guide outlines the critical design factors you must consider and explains why partnering with the best graphic overlay manufacturer is essential to get it right.

1. Application Environment

a. Indoor vs. Outdoor Use

Your design must suit the overlay's physical environment. For outdoor applications, prioritize UV resistance, moisture protection, and wide temperature tolerance.

b. Chemical & Abrasion Resistance

Industries like healthcare or manufacturing require overlays that resist frequent cleaning, harsh chemicals, or friction from repeated use.

Tip: The best graphic overlay manufacturers offer materials with enhanced durability, like hard-coated polyester or textured polycarbonate.

2. Material Selection

- Choosing the right material affects performance, print quality, and longevity.

- Polyester (PET) – Excellent durability, chemical resistance, and flexibility. Best for demanding applications.

- Polycarbonate (PC) – Great for indoor use with high optical clarity and vibrant color printing.

- Vinyl (PVC) – Low-cost option suitable for short-term or promotional uses.

3. Surface Texture & Finish

The overlay’s feel and appearance are influenced by its surface finish:

- Matte: Reduces glare and fingerprint visibility.

- Glossy: Provides a premium look and enhanced color depth.

- Textured: Offers tactile feedback and improved grip.

Well-known manufacturers also provide anti-glare, hard-coated, or anti-microbial options for specialty environments.

4. Color, Print, and Graphics

Visual consistency and clarity are critical for both branding and function.

Pantone Color Matching ensures brand accuracy.

Opaque and Transparent Windows are useful for LEDs or display areas.

Embossing and Debossing add tactile guidance to flat surfaces.

A reliable manufacturing partner uses advanced screen and digital printing techniques to maintain sharpness and color accuracy across production batches.

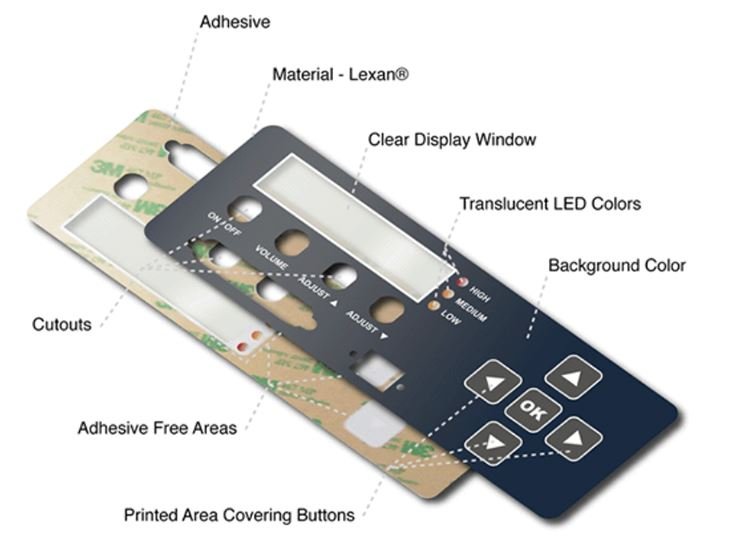

5. Adhesive and Backing Layers

The adhesive must match your overlay material and application surface:

3M or equivalent industrial adhesives ensure long-term bonding.

Consider whether you need removable, permanent, or high-temperature adhesives.

Leading manufacturers will also test adhesive performance across different substrates (metal, plastic, powder coating, etc.).

6. Functional Enhancements

Your overlay can include additional functional features:

- Embossed Buttons: Improve tactile feedback.

- Windows & Cutouts: Allow visibility of displays or access to sensors.

- Backlighting Support: Design for light diffusion or translucency where needed.

7. Compliance and Safety

Depending on your industry, overlays may need to comply with:

RoHS, REACH, or UL 94 V-0 flame retardant standards.

FDA-grade materials for medical and food-contact applications.

Top-tier suppliers are well-versed in regulatory requirements and offer certified materials.

8. Prototyping and Production Scalability

Before mass production, validate your overlay with a prototype:

Test fit, feel, and performance under real conditions.

Adjust for design improvements before full-scale rollout.

Why it matters: The best graphic overlay manufacturer provides fast-turnaround prototyping, precision die-cutting, and consistent quality, even in large volumes.

9. Conclusion

Designing a high-performance graphic overlay involves more than selecting a material or printing a logo. It requires strategic thinking about the user interface, application environment, and manufacturing process. Working with the best graphic overlay manufacturer ensures not only technical accuracy but also brand consistency, durability, and end-user satisfaction.

If you’re ready to bring your interface design to life, choose a supplier with the materials, expertise, and customization capabilities to meet your demands, from concept to production.