Custom Frozen Food Boxes in the UK and the Role of Packaging Sleeves

For businesses, custom frozen food boxes in UK and sleeves for food packaging are essential tools that protect products during transportation and enhance brand recognition.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

In the competitive frozen food industry, packaging plays a crucial role in preserving freshness, ensuring safe handling, and creating a lasting impression on customers. For businesses, custom frozen food boxes in the UK and sleeves for food packaging are essential tools that protect products during transportation and enhance brand recognition.

Importance of Custom Frozen Food Boxes

Frozen food boxes must maintain product integrity by keeping items at the required temperature, protecting them from moisture, and safeguarding them from external impacts. Here are some reasons custom frozen food boxes are essential:

-

Product Freshness and Preservation: Properly insulated boxes keep food items fresh, even during extended periods of transportation or storage. Insulated materials like coated cardboard or laminated cardboard protect against moisture and temperature changes.

-

Branding and Visibility: Custom frozen food boxes allow companies to use unique designs and logos, ensuring their products stand out on store shelves. Custom branding increases customer recognition and sets the product apart from competitors.

-

Environmental Considerations: Many consumers today prefer eco-friendly options. Using biodegradable or recyclable materials for frozen food packaging can meet this demand, providing businesses with a sustainable and responsible image.

-

Compliance with Regulations: Frozen food packaging in the UK must meet food safety standards to avoid contamination or degradation of quality. Custom packaging options make it easier to meet these standards while adding branded aesthetics.

-

Enhanced Product Safety: Custom frozen food boxes provide robust protection, reducing damage during transit and keeping products safe from potential contaminants, moisture, and temperature changes.

Role of Packaging Sleeves in Frozen Food and Other Food Products

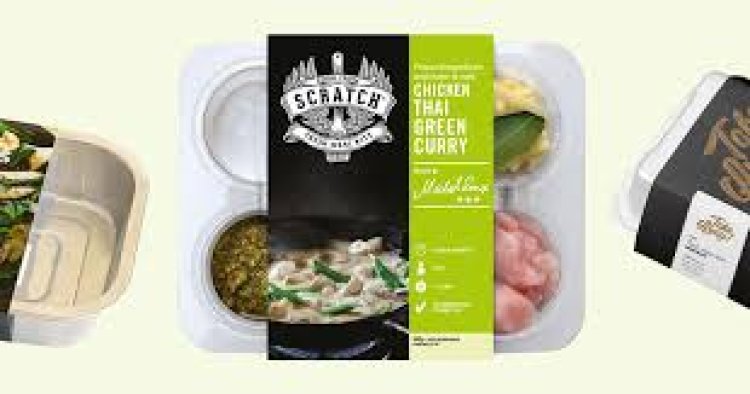

Packaging sleeves are versatile and commonly used for various food products. For frozen food, they are often paired with custom boxes to provide added branding and product details.

Key Benefits of Using Packaging Sleeves for Food Products

-

Cost-Efficiency: Sleeves are cost-effective since they require less material than fully custom-printed boxes. This makes them an affordable branding option for companies of all sizes.

-

Improved Product Presentation: Packaging sleeves provide a professional look, showcasing brand details, nutritional information, and preparation instructions without altering the primary packaging.

-

Enhanced Flexibility: Sleeves can be easily modified for seasonal or promotional campaigns without altering the core packaging, giving companies flexibility in marketing.

-

Sustainable Options: Eco-conscious consumers will appreciate sleeves made from recycled materials or biodegradable options. Environmentally friendly packaging appeals to a growing demographic of green-conscious customers.

-

Customizable Design Options: Companies can use custom designs and brand elements on sleeves to communicate their brand story effectively. A simple yet eye-catching sleeve with relevant product information can leave a lasting impression on consumers.

-

Multi-Functional Uses: Packaging sleeves aren’t limited to frozen food products—they work well with bakery items, dairy products, ready-to-eat meals, and more. Businesses in various food sectors can benefit from custom sleeves to create brand consistency across different product lines.

Designing Effective Custom Frozen Food Boxes and Sleeves

Effective packaging design goes beyond aesthetics; it plays a role in customer engagement and satisfaction. Here are some essential design elements to consider:

-

Branding Consistency: Use brand colors, logos, and typography to maintain a consistent image. This is crucial for brand recognition, especially if your products are in highly competitive categories.

-

Clear Product Information: Include essential information, such as ingredients, nutritional content, allergen warnings, and cooking instructions. This transparency builds trust with customers and aids them in making informed decisions.

-

Eco-Friendly Materials: Opt for sustainable materials like recycled cardboard or biodegradable coatings. Many consumers prioritize sustainability, making this an impactful feature for packaging.

-

Durability and Structural Integrity: Frozen food boxes must be durable enough to withstand low temperatures and potential moisture exposure. High-quality, durable materials prevent box damage and ensure that the food stays safe during transit and storage.

-

Easy Storage and Handling: Custom boxes with convenient shapes and stackable designs make it easier for retailers to store and handle products, ultimately benefitting consumers as well.

-

Attractive Design Elements: Incorporate unique visuals that highlight the product's qualities. Use engaging designs, images, and color schemes that resonate with the target audience while keeping the packaging clutter-free.

Types of Frozen Food Packaging and Sleeve Materials

Selecting the right materials for frozen food packaging and sleeves is crucial to maintaining product quality and meeting regulatory standards. Here are popular options:

-

Corrugated Cardboard: Commonly used for outer packaging, corrugated cardboard provides durability and insulation. It’s also suitable for printing brand elements on the box's exterior.

-

Polyethylene (PE) and Polypropylene (PP): These materials are moisture-resistant and work well for lining frozen food boxes, keeping products safe from freezer burn.

-

Biodegradable Materials: Companies aiming for sustainability can opt for biodegradable materials like recycled cardboard for sleeves and box exteriors. Plant-based plastics are also gaining traction in frozen food packaging.

-

Insulated Liners and Coatings: Insulation liners, like foil or foam, are used to maintain temperatures and prevent condensation. For eco-friendly insulation, biodegradable or recyclable liners offer an alternative to traditional foils and plastics.

-

Kraft Paper and Recycled Board for Sleeves: Kraft paper and recycled board sleeves provide a natural, rustic appearance that appeals to eco-conscious consumers. Kraft is also easily customizable for printing logos, instructions, and more.

How Custom Frozen Food Boxes Enhance Customer Experience

Custom packaging is crucial for an enhanced customer experience. Here’s how custom frozen food boxes in UK and sleeves improve the overall experience:

-

Better First Impressions: Eye-catching packaging instantly draws attention, and a well-designed custom box creates a positive first impression.

-

User-Friendliness: Consumers appreciate easy-to-open packaging, especially for frozen foods. Features like perforated lines or pull tabs make the experience hassle-free.

-

Information Accessibility: Clearly visible instructions or branding on the box or sleeve simplify product use and provide clarity for consumers.

-

Eco-Friendly Appeal: Sustainable packaging attracts customers who prioritize eco-friendly purchases. Companies that invest in sustainable custom packaging solutions build a loyal customer base over time.

Trends in Frozen Food Packaging

Frozen food packaging has evolved with advancements in design and materials. Here are some emerging trends:

-

Minimalist and Clean Designs: Simple, clean designs with an emphasis on product details are trending. Minimalist designs make the brand appear sophisticated and let consumers focus on the product's key features.

-

Transparent Elements: Some packaging incorporates transparent windows or translucent designs, allowing consumers to see the product inside, which increases trust and appeal.

-

Personalized Branding: Personalized packaging using variable data printing allows brands to change design elements for limited editions or regional promotions, offering a unique experience.

-

Smart Packaging: With advancements in technology, some companies are incorporating QR codes or NFC tags on packaging to share information about product origin, ingredients, or brand story. This trend is gaining popularity and helps brands connect more closely with consumers.

-

Sustainable Packaging: The shift towards biodegradable, recyclable, and compostable materials is stronger than ever, aligning with consumer demand for environmentally responsible products.

Conclusion

Custom frozen food boxes and packaging sleeves for food items are essential for maintaining product quality, enhancing brand visibility, and satisfying customer demands. Whether focusing on sustainability, durability, or aesthetic appeal, investing in high-quality custom packaging solutions can significantly benefit businesses in the frozen food industry.