Container Liners: Optimizing Bulk Transport with Maximum Protection

Container liners are an essential tool for industries that deal with the transportation of bulk materials. They offer a cost-effective, sustainable, and efficient solution for protecting products during transit. The use of container liner sheets in India continues to rise as more industries recognize the value of this flexible packaging option. With Indian Container Liners manufacturers leading the way in innovation and customization, businesses can find the perfect liner solution for their needs.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Container liners are essential for industries that require the safe and efficient transport of bulk goods. These liners are designed to transform a standard shipping container into a secure environment for carrying bulk materials, ensuring that products such as chemicals, food, agricultural goods, and minerals arrive at their destination without contamination or loss. In countries like India, Container Liners manufacturers play a key role in producing high-quality liners that meet international standards.

What Are Container Liners?

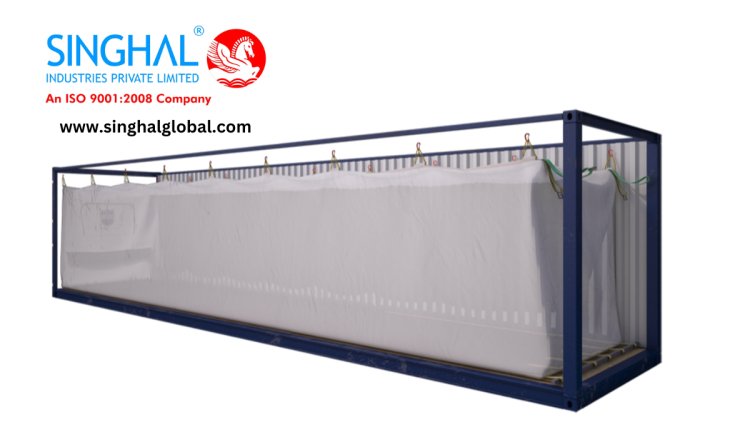

Container liners are large, flexible bags or sheets that are fitted inside standard shipping containers. They serve as a protective layer between the container walls and the bulk material being transported. Made from materials such as polyethylene (PE) or polypropylene (PP), container liners offer a cost-effective and efficient solution for the transportation of dry, bulk materials, liquids, and powders.

The use of Container liner sheets in India is growing due to their versatility, especially in sectors like agriculture, chemicals, food, and pharmaceuticals. The liners ensure that the goods remain uncontaminated and protected from external elements like moisture, dust, and temperature fluctuations.

Types of Container Liners

1. Dry Bulk Liners

These liners are used to transport dry bulk goods such as grains, seeds, sugar, malt, and chemicals. They fit snugly into standard 20ft or 40ft containers, creating a barrier that prevents the cargo from coming into contact with the container walls.

2. Liquid Bulk Liners

Designed for transporting non-hazardous liquids, liquid bulk liners allow containers to carry products like food-grade oils, juices, and chemicals. These liners are often fitted with special inlet and outlet valves for easy loading and unloading.

3. Thermal Liners

Thermal liners are used for temperature-sensitive goods. They provide insulation and protect cargo from extreme temperature changes during transit. This makes them ideal for transporting food, pharmaceuticals, and other sensitive materials.

4. Foil Liners

These are made of aluminum foil combined with other insulating materials. They provide excellent protection against moisture, heat, and light, making them suitable for goods like cocoa, coffee, and specialty chemicals.

Benefits of Container Liners

1. Cost-Efficiency

Container liners eliminate the need for additional packaging materials, such as individual bags or sacks, reducing packaging costs. They maximize container space by allowing bulk materials to be shipped directly without extra layers of packaging.

2. Protection Against Contamination

One of the primary reasons for using container liners is to ensure that the bulk materials are protected from contamination. The liners prevent direct contact with the container’s interior, reducing the risk of product degradation due to dust, moisture, or previous residues from previous shipments.

3. Increased Flexibility

Container liners can be customized for different applications and container sizes. Many Container Liners manufacturers offer liners tailored to specific cargo requirements, including inlet and outlet valves, anti-static features, and reinforced designs for heavier materials.

4. Quick Installation and Easy Handling

The installation of container liners is quick and simple. This efficiency in setup minimizes loading and unloading times, helping companies to optimize their logistics and reduce operational costs.

5. Sustainability

Many container liners are designed to be recyclable or reusable, which makes them a more sustainable option compared to traditional single-use packaging. This is particularly beneficial for industries looking to reduce their environmental impact.

Applications of Container Liners

1. Agriculture

The agricultural sector widely uses container liners to transport bulk grains, seeds, and fertilizers. The liners ensure that the products remain dry and free from contamination during transport. Given the wide range of agricultural exports, container liner sheet in India is particularly in demand for transporting commodities like rice, wheat, and pulses.

2. Food Industry

Container liners are crucial for transporting dry food products such as sugar, flour, and spices. In the liquid food sector, liners are used to transport oils, juices, and syrups. The food-grade quality of these liners ensures that there is no risk of contamination during transit.

3. Chemical Industry

In the chemical industry, container liners are used for the transport of bulk chemicals, powders, and granules. These liners are often customized with anti-static properties to ensure safety when handling volatile or hazardous materials.

4. Pharmaceuticals

The pharmaceutical industry relies on container liners for the transport of raw materials, ingredients, and finished products. The liners help maintain the purity of pharmaceutical goods by providing protection from external contaminants.

Container Liner Manufacturers in India

India is a hub for Container Linersmanufacturers, producing high-quality liners for both domestic and international markets. Indian manufacturers are known for adhering to global quality standards, ensuring that their liners meet the stringent requirements of industries such as food, pharmaceuticals, and chemicals.

These manufacturers offer a wide range of container liner solutions, including custom designs for specific industries. They use advanced technology and high-quality raw materials to produce liners that offer strength, durability, and excellent protection for bulk goods.

Conclusion

Container liners are an essential tool for industries that deal with the transportation of bulk materials. They offer a cost-effective, sustainable, and efficient solution for protecting products during transit. The use of container liner sheets in India continues to rise as more industries recognize the value of this flexible packaging option. With Indian Container Liners manufacturers leading the way in innovation and customization, businesses can find the perfect liner solution for their needs.

FAQs

1. What materials are container liners made from?

Container liners are typically made from high-quality polyethylene (PE) or polypropylene (PP), both of which offer strength, flexibility, and resistance to moisture. Some liners may also include additional features such as anti-static properties or thermal insulation.

2. Can container liners be reused?

Yes, many container liners are designed to be reusable, depending on the type of material and application. Reusable liners are an eco-friendly option that reduces packaging waste and lowers overall costs.

3. What types of goods can be transported using container liners?

Container liners are used for transporting a wide range of bulk goods, including dry products like grains, powders, and chemicals, as well as liquids such as oils and juices. Specialized liners are available for temperature-sensitive or hazardous materials.

4. Are container liners customizable?

Yes, Container Liners manufacturers offer a variety of customization options, including different sizes, shapes, and material types. Liners can also be fitted with specialized features such as valves for liquid discharge, anti-static properties, and insulation for temperature control