Computer-Aided Design (CAD): Revolutionizing the Way We Design and Create

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

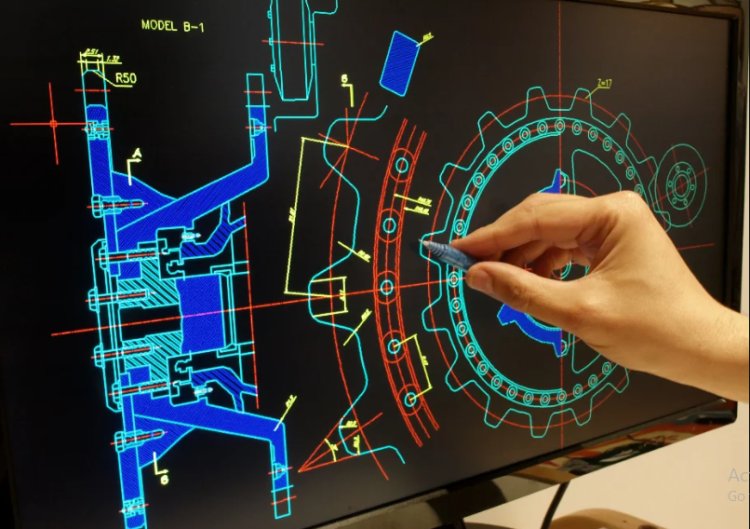

Computer-Aided Design (CAD) has profoundly transformed the way industries approach design and manufacturing. By utilizing Computer Aided Design, CAD software allows designers, engineers, and architects to create detailed and precise drawings and models for products, structures, and systems. CAD has become an indispensable tool across numerous sectors, including automotive, aerospace, architecture, civil engineering, and electronics. This article explores the significance of CAD, its applications, types, benefits, and how it continues to evolve in the design landscape.

What is Computer-Aided Design (CAD)?

Computer-Aided Design refers to the use of computer software to assist in the creation, modification, analysis, and optimization of designs. CAD is a crucial part of the design process, allowing professionals to visualize their ideas in 2D or 3D formats. It facilitates accurate and efficient production of technical drawings, blueprints, and digital models. These models can then be analyzed for performance, functionality, and manufacturability, providing a clear and error-free representation of the final product.

CAD systems employ specialized software that can generate and manipulate complex shapes and geometries. The advancement of CAD tools has dramatically reduced the time and effort required to produce high-quality designs, making the design process more cost-effective and less prone to human error.

Types of CAD Systems

There are various types of CAD systems tailored to different industries and use cases. These systems can be broadly categorized into:

1. 2D CAD

2D CAD software is used to create flat, two-dimensional drawings and layouts. It allows designers to define geometries, dimensions, and relationships in a straightforward manner. Industries such as architecture and civil engineering often rely on 2D CAD for drafting floor plans, site layouts, and structural diagrams.

2. 3D CAD

3D CAD offers a more advanced approach by enabling the creation of three-dimensional models. These models can be rotated and viewed from any angle, providing a more accurate representation of the final product. 3D CAD is extensively used in industries like automotive, aerospace, and consumer electronics, where product designs require detailed visualizations of parts, assemblies, and complex systems.

3. Solid Modeling

Solid modeling is a subset of 3D CAD that focuses on creating solid objects with real-world physical properties. It allows users to simulate the physical behavior of designs, including stress and strain, fluid dynamics, and thermal performance. This is essential in engineering and product development, where the physical properties of a design must be tested before manufacturing.

4. Surface Modeling

Surface modeling is used to design and manipulate complex shapes, particularly in industries like automotive and industrial design. Surface modeling focuses on defining the outer surface of an object, which is essential when designing smooth, curved surfaces or organic shapes. This type of modeling is often used in conjunction with solid modeling to create complex geometries.

5. Parametric CAD

Parametric CAD systems allow designers to create models based on parameters and constraints. By defining relationships between components, changes made to one part of the design can automatically update other related parts. This makes parametric CAD highly efficient for managing large and complex designs where changes are frequent, such as in the automotive or aerospace industries.

Applications of CAD

CAD is used in virtually every field that involves product design or construction. Some key industries where CAD plays a crucial role include:

1. Architecture and Construction

In architecture, CAD software helps architects and engineers design buildings, bridges, and infrastructure. It is used to create floor plans, elevation drawings, and detailed construction documents. 3D CAD models allow architects to visualize how a building will look once completed and make modifications before construction begins, improving the efficiency and accuracy of the design process.

2. Automotive Design

In the automotive industry, CAD is essential for designing vehicles and their components. CAD allows for the development of 3D models of car parts such as engines, chassis, and body panels, helping to optimize the design for functionality, safety, and aerodynamics. Engineers can test and simulate the performance of various parts before they are physically manufactured, reducing the cost and time spent on prototyping.

3. Aerospace

The aerospace industry relies heavily on CAD for the design and testing of aircraft and spacecraft components. CAD allows aerospace engineers to create detailed models of complex systems and ensure that all parts fit together precisely. The precision of CAD models ensures that every component meets strict safety and performance standards, which is critical in aviation and space exploration.

4. Product Design and Manufacturing

CAD has revolutionized product design across various consumer goods industries, such as electronics, furniture, and medical devices. By creating detailed digital models, designers can ensure that products are manufacturable and meet user requirements. CAD also aids in rapid prototyping, where 3D models can be converted into physical prototypes using technologies like 3D printing.

5. Civil Engineering

Civil engineers use CAD to design infrastructure projects such as highways, dams, and water treatment facilities. CAD helps civil engineers create detailed designs that account for factors like terrain, environmental considerations, and structural integrity. These designs are used to guide the construction process and ensure that projects meet safety and regulatory standards.

Benefits of CAD

The integration of CAD into the design process brings several advantages that significantly enhance productivity, accuracy, and innovation.

1. Increased Precision

CAD software allows for highly accurate drawings and models. The precision of CAD reduces the possibility of human error, ensuring that every part of a design is correctly dimensioned and aligned. This is crucial in industries such as aerospace and automotive, where even the smallest error can have serious consequences.

2. Time Efficiency

CAD tools streamline the design process by allowing designers to quickly make changes and iterate on designs. Features such as copy-paste, drag-and-drop, and automated calculations save time that would otherwise be spent on manual drafting or modification. Moreover, 3D CAD systems enable faster visualization, helping designers spot potential issues early on.

3. Cost Savings

By reducing errors and the need for physical prototypes, CAD helps save both time and money. Changes can be made virtually before any physical manufacturing begins, minimizing the cost of making mistakes. Furthermore, CAD allows for the optimization of designs, ensuring that materials are used efficiently and manufacturing processes are cost-effective.

4. Collaboration

CAD systems enable better collaboration among design teams, even when members are geographically dispersed. Designs can be shared digitally, and modifications can be tracked and reviewed in real time. This is particularly useful in large-scale projects where multiple teams need to work together to bring a product to life.

5. Enhanced Visualization

With the advent of 3D modeling, CAD software allows designers to create lifelike visualizations of their designs. These 3D models provide a more realistic representation of the final product, helping stakeholders better understand and evaluate designs before they are manufactured.

The Future of CAD

As technology continues to evolve, so does the capability of CAD. Emerging trends in CAD include the integration of artificial intelligence (AI) and machine learning, which can automate design processes, predict design flaws, and optimize designs in real time. Additionally, virtual reality (VR) and augmented reality (AR) are expected to play a significant role in the future of CAD, enabling designers to interact with 3D models in immersive environments. 3D printing also continues to evolve, allowing for rapid prototyping and manufacturing directly from CAD models.

Conclusion

Computer-Aided Design has transformed the world of design and manufacturing, making it easier to create detailed, accurate, and innovative products across various industries. From 2D drawings to complex 3D models, CAD tools have become an essential part of the design process, driving efficiency, collaboration, and cost savings. As technology advances, CAD systems will continue to evolve, further enhancing their capabilities and reshaping the way products and systems are designed in the future.