Choosing the Right Helium Leak Testing Machine for Your Needs

Find the perfect helium leak testing machine for your application with our guide. Explore key factors to consider and make an informed decision today

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Selecting the right helium leak testing machine is crucial for ensuring product quality, safety, and efficiency in your manufacturing process. With various models and technologies available, finding the perfect fit can be challenging. This article will guide you through the essential factors to consider when choosing a helium leak testing machine, ensuring that you make an informed decision that aligns with your specific needs.

Understanding the Basics of Helium Leak Testing

A non-destructive technique called helium leak testing is used to find leaks in different parts and systems. Because of its small molecular size and inert characteristics, helium is used as a tracer gas in this process. By detecting the presence of helium escaping from the test object, a helium leak testing system may find even the smallest leaks. In sectors where accuracy and dependability are crucial, such as aerospace, automotive, and medical devices, this technique is commonly utilized.

Identifying Your Testing Requirements

Determining your unique testing needs is crucial before choosing a helium leak testing apparatus. Take into account the kinds of goods you plan to test, the anticipated rates of leakage, and the volume of manufacturing. You can determine the machine's required sensitivity, speed, and capacity by having a thorough understanding of these parameters. For instance, an extremely sensitive device can be required for testing high-precision components. On the other hand, a machine with quick cycle times can be more suitable if your production volume is high.

Sensitivity and Detection Range

The sensitivity and detection range of a helium leak testing device are among the most important considerations. The lowest leak rate that the device can identify is referred to as its sensitivity. Various applications call for varying degrees of sensitivity. For example, in the medical device sector, patient safety depends on finding even the smallest leakage. However, a wider detection range might work well for applications like HVAC systems. Make sure the machine you select satisfies the sensitivity needs of the particular application you have in mind.

Speed and Throughput

One important factor to take into account is production speed, particularly in high-volume manufacturing settings. Your choice of helium leak testing equipment should be able to process the necessary amount of data without sacrificing accuracy. Certain machines can operate at fast speeds and with short cycle durations because they are built for rapid testing. However, there can be sensitivity trade-offs associated with quicker machinery. Maintaining the effectiveness of your quality control procedures without causing production to lag requires striking a balance between speed and precision.

Automation and Integration Capabilities

Automation features are a common element of modern helium leak testing equipment, increasing productivity and lowering human error. Production lines can incorporate automated equipment to enable continuous leak checking without the need for human interaction. Consistency and speed are crucial in large-scale manufacturing, where this integration is especially helpful. Depending on your production setup and financial constraints, evaluate if you require a fully automated system or a machine that is just partially automated. Additionally, automation can lower labor expenses and boost overall productivity.

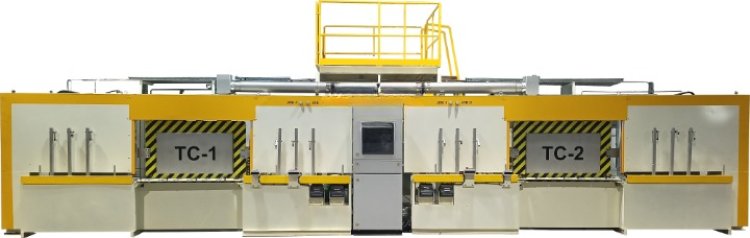

Machine Size and Footprint

Particularly if your business has limited space, the helium leak testing machine's size and footprint are crucial considerations. Certain devices are portable and small, which makes them ideal for testing applications that require mobility in small areas. Some are bigger and might need their area on the manufacturing floor. Make sure the machine's dimensions fit the design of your building and that integrating it into your current production process will be simple. Take into account the machine's ease of installation as well as any particular operating needs.

Maintenance and Support

To guarantee the long-term functionality of your helium leak testing apparatus, maintenance is essential. Frequent maintenance guarantees consistent accuracy and helps avert malfunctions. Think about the convenience of getting replacement parts and the availability of technical support when selecting a machine. To maintain some devices, specific knowledge may be needed, thus it's critical to make sure your workforce is properly taught. To maintain the proper operation of your machine, you should also take into account the manufacturer's track record for customer service and the availability of service contracts.

Cost Considerations

Although it shouldn't be your only deciding element, cost should be taken into account. The cost of helium leak testing equipment varies greatly based on its features, automation degree, and sensitivity. Make sure your budget strikes a balance between your needs and what you have. Remember that buying a high-quality machine can save you money in the long run by lowering maintenance expenses, waste, and recalls. Take into account the entire cost of ownership, which includes the original purchase price as well as ongoing maintenance and operating costs.

Energy Efficiency

Energy efficiency in production is an issue that matters more and more. You can decrease the environmental impact of your production process and save running costs by using a helium leak testing machine with lower energy consumption. Look for appliances that use helium more effectively or that have energy-saving features like automatic shut-off when not in use. Energy-efficient machines may cost more upfront, but they can save a lot of money throughout the machine's life.

Compliance with Industry Standards

You might have to make sure that your helium leak testing equipment conforms with particular standards or laws, depending on your line of work. For instance, to guarantee patient safety, machinery in the medical device sector must adhere to strict regulatory standards. Similar to this, adherence to industry standards is essential for product performance and safety in the aerospace and automobile industries. Make sure that the machine you select can readily be validated or certified as needed and that it can meet these standards.

Customization and Flexibility

Since each manufacturing process is different, your helium leak testing equipment should be able to meet your particular requirements. Certain machines have configurable features that let you adjust things like data reporting, testing parameters, and sensitivity to suit your needs. Additionally, if your production needs alter over time, flexibility is crucial. A machine that can adjust to various items or testing conditions will be more valuable and require fewer expenditures on new equipment down the road.