Buying Battery Case & Paint Bucket Molds from China

Learn expert tips on sourcing quality battery case moulds and paint bucket moulds from Chinese manufacturers. Discover key factors, costs, and supplier verification methods.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

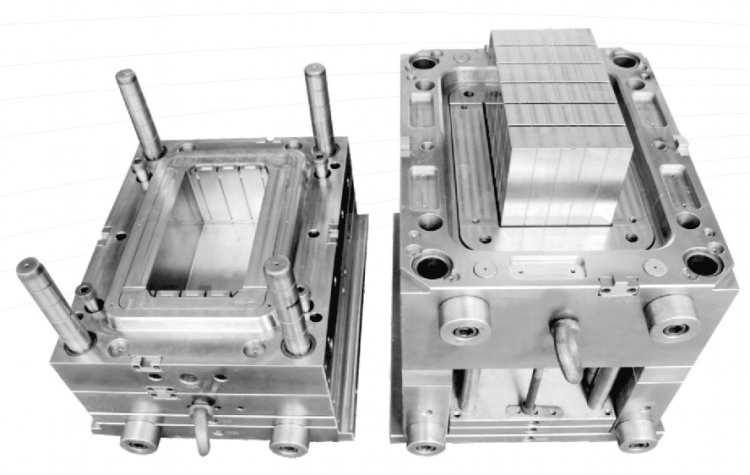

Complete Guide to Buying Battery Case & Paint Bucket Molds from China

Are you looking to source high-quality injection molds from China? As an industry expert with two decades of experience, I'll guide you through the essential steps of purchasing reliable battery case manufacturing molds and professional paint container molds from Chinese suppliers.

Understanding Chinese Mold Manufacturing Market

The Chinese mold manufacturing industry has evolved significantly over the past decade. When sourcing battery case moulds or paint bucket moulds, you'll find:

• Advanced manufacturing facilities equipped with state-of-the-art CNC machines • Competitive pricing structures that vary by region and supplier expertise • Diverse quality levels ranging from basic to high-precision molds

Key Factors in Mold Selection

Before contacting suppliers for your battery case mould or paint bucket mould requirements, consider these crucial aspects:

• Material specifications and compatibility with your production needs • Expected annual production volume and cycle time requirements • Surface finish requirements and special features needed in the final product • Mold life expectancy and maintenance considerations

Cost Considerations and Budgeting

Understanding the cost structure helps in negotiating better deals:

| Mold Type | Basic Quality | Medium Quality | Premium Quality |

|---|---|---|---|

| Battery Case Mould | $8,000-12,000 | $15,000-25,000 | $30,000-45,000 |

| Paint Bucket Mould | $10,000-15,000 | $20,000-30,000 | $35,000-50,000 |

Hidden Costs to Consider

When budgeting for your mold investment, remember these additional expenses:

• Modification costs during sampling phase • Shipping and customs clearance fees • Installation and commissioning expenses • Spare parts inventory requirements

Supplier Verification Process

Finding reliable suppliers for battery case moulds and paint bucket moulds requires thorough verification:

• Review company certifications and quality management systems • Check previous project portfolios and client references • Evaluate their technical design capabilities • Assess their post-sale support infrastructure

Red Flags to Watch For

Be cautious of these warning signs when evaluating suppliers:

• Unusually low prices compared to market standards • Reluctance to provide detailed technical specifications • Limited communication during the inquiry phase • Lack of quality control documentation

Technical Specifications Review

When reviewing technical specifications for your <a href="https://www.plasticmoulds.net/plastic-battery-box-mould">custom battery enclosure tooling</a> or <a href="https://www.plasticmoulds.net/paint-bucket-molds">industrial paint container molds</a>, focus on:

• Material flow analysis and gate location optimization • Cooling system design and efficiency • Ejection system configuration • Steel grade selection for different mold components

Quality Control Measures

Implementing strict quality control procedures is essential:

• First article inspection requirements • Dimensional accuracy verification methods • Surface finish inspection criteria • Mold trial run parameters and acceptance criteria

Sampling and Testing Phase

During the sampling phase, ensure these aspects are covered:

• Initial sample approval process • Material testing requirements • Production cycle time verification • Quality consistency checks across multiple cavities

Contract and Payment Terms

Protect your investment with clear contract terms:

• Detailed payment milestone schedule • Quality guarantee clauses • Delivery timeline commitments • After-sales service agreements

Shipping and Logistics

Consider these aspects when arranging shipment:

• Packaging requirements for heavy molds • Insurance coverage during transit • Documentation requirements for customs clearance • Transportation method selection based on urgency

After-Sales Support Expectations

Establish clear expectations for:

• Technical support during mold installation • Maintenance schedule and requirements • Spare parts availability and delivery time • Troubleshooting assistance protocols

Long-term Maintenance Planning

Ensure sustainable production by:

• Developing preventive maintenance schedules • Training local technicians for basic maintenance • Establishing spare parts inventory systems • Creating troubleshooting protocols

This comprehensive guide should help you navigate the complex process of sourcing battery case moulds and paint bucket moulds from China. Remember that successful mold procurement requires careful attention to detail, thorough supplier verification, and clear communication throughout the process.

Remember to conduct thorough due diligence and consider working with experienced sourcing agents if you're new to importing molds from China. The initial investment in quality and reliability will pay dividends throughout the mold's lifecycle.