A Comprehensive Guide to Versatile, Durable, and Cost-Effective Material

Polypropylene (PP) corrugated sheets are gaining popularity across various industries due to their versatility, durability, and cost-effectiveness. These sheets, also known as PP flute boards or plastic corrugated sheets, Pulkit Plastic Products are widely used in packaging, signage, construction, and many other sectors. Their lightweight yet robust properties make them an ideal solution for countless applications.

This article provides a detailed look into Corrugated Plastic Sheet, explaining what they are, their benefits, common applications, environmental impact, and answers to frequently asked questions (FAQs) about their usage.

What Are PP Corrugated Sheets?

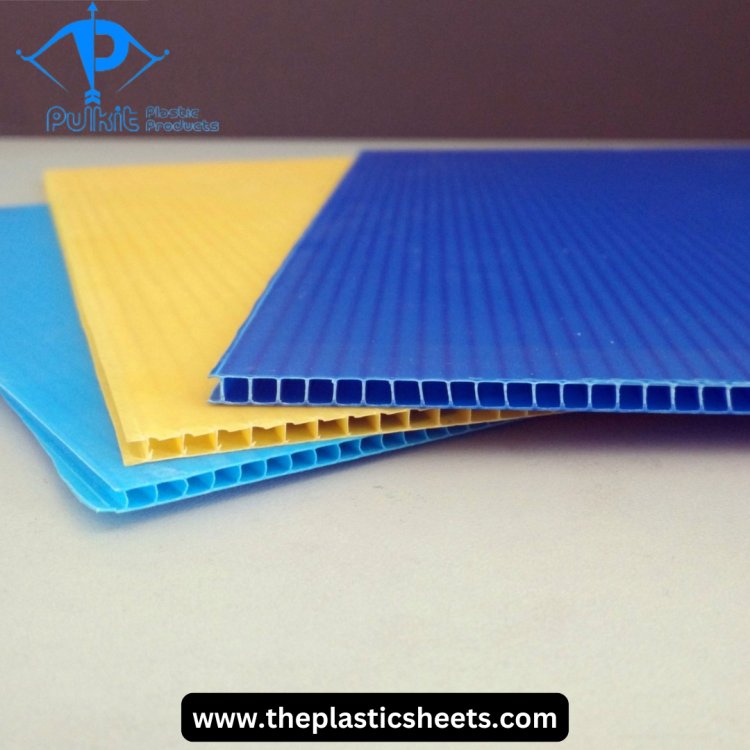

PP corrugated sheets are lightweight, rigid, and highly durable sheets made from polypropylene plastic. These sheets consist of two flat layers separated by a series of interconnected ribs, forming a fluted or corrugated structure. The corrugated design adds strength and durability to the material without significantly increasing its weight.

Due to the characteristics of polypropylene, PP corrugated sheets offer a range of beneficial features, including resistance to moisture, chemicals, and impact, making them suitable for both indoor and outdoor use.

Key Features of PP Corrugated Sheets

-

Lightweight Yet Strong

PP corrugated sheets are incredibly lightweight, which makes them easy to handle and transport. Despite their lightness, they are strong enough to provide excellent protection for fragile or delicate items. -

Water and Moisture Resistance

One of the key advantages of PP corrugated sheets is their ability to resist water and moisture. Unlike cardboard or paper-based materials, PP sheets do not warp or deteriorate when exposed to water, making them perfect for outdoor applications or environments with high humidity. -

Chemical Resistance

Polypropylene is resistant to many chemicals, including acids, alkalis, and solvents, which means PP corrugated sheets can be used in harsh environments where other materials might degrade or corrode. -

Impact Resistance

The corrugated design of PP sheets provides excellent shock absorption, protecting items from damage due to impact. This is particularly useful in packaging, where products need to be protected during shipping and handling. -

Easy to Customize

PP corrugated sheets can be easily cut, printed on, or die-cut to specific shapes and sizes, making them highly versatile for a variety of applications. -

Eco-Friendly and Recyclable

PP corrugated sheets are 100% recyclable, contributing to sustainable practices in industries that prioritize environmental responsibility. -

UV Stabilization (Optional)

UV stabilization can be added to PP corrugated sheets to protect them from the harmful effects of prolonged exposure to sunlight, which can cause fading or weakening of non-stabilized plastic.

Common Applications of PP Corrugated Sheets

The corrugated plastic sheet Manufacturers are used in a variety of industries, from packaging to agriculture. Here are some of the most common applications:

1. Packaging Solutions

PP corrugated sheets are widely used in the packaging industry due to their strength, lightweight nature, and durability. They are ideal for creating boxes, cartons, and protective packaging for shipping delicate or valuable items. These sheets can also be made into reusable packaging solutions for industries looking to reduce their environmental impact.

Example: Reusable plastic crates or containers used in logistics, manufacturing, and storage.

2. Signage and Advertising

Due to their smooth surface and ease of printing, PP corrugated sheets are often used for outdoor and indoor signage. These sheets can be printed with vibrant colors and sharp images, making them perfect for promotional signs, real estate signs, and temporary event signage.

Example: Yard signs for political campaigns or real estate listings.

3. Construction Industry

PP corrugated sheets are used in construction as protection boards during building and renovation projects. They protect surfaces such as floors, walls, and windows from damage during the construction process. The sheets are easy to install and remove, making them a convenient solution for construction projects.

Example: Temporary surface protection for floors in newly constructed homes.

4. Agriculture and Horticulture

PP corrugated sheets are used in agriculture and horticulture for applications like greenhouse dividers, protective plant covers, and seedling trays. Their resistance to water and chemicals makes them ideal for use in farming environments.

Example: Greenhouse panels to regulate temperature and protect plants from harsh weather conditions.

5. Automotive Industry

In the automotive industry, PP corrugated sheets are used as partitions, dividers, and protective packaging for vehicle parts. The durability of these sheets ensures that heavy and delicate auto parts are transported safely without damage.

Example: Protective dividers for transporting car components.

6. Arts and Crafts

Due to their ease of cutting and shaping, PP corrugated sheets are also used in DIY projects, arts and crafts, and model-making. They provide a sturdy, lightweight material that can be molded or painted for creative uses.

Example: Creating school projects or models for architecture students.

Benefits of Using PP Corrugated Sheets

-

Cost-Effective

PP corrugated sheets are relatively inexpensive compared to other materials like metal, wood, or even traditional cardboard. Their long lifespan, especially in reusable applications, makes them a cost-efficient solution for businesses. -

Reusable

Unlike single-use cardboard, PP corrugated sheets can be used multiple times before showing signs of wear and tear. This reusability reduces costs over time and contributes to sustainability by decreasing the amount of waste generated. -

Customizable and Versatile

PP corrugated sheets can be easily tailored to specific needs, making them highly versatile. They can be cut, shaped, printed on, and even color-coded to suit different applications. -

Eco-Friendly Option

Polypropylene is a fully recyclable plastic, meaning that PP corrugated sheets can be reprocessed into new products, reducing waste and conserving resources. Many industries now prioritize materials that contribute to circular economies, and PP corrugated sheets are an excellent option in this regard. -

Weather and UV Resistance

With optional UV stabilization, PP corrugated sheets can be used outdoors without suffering from damage caused by prolonged sun exposure. This is particularly useful for signage and agricultural applications. -

Easy to Handle and Install

The lightweight nature of PP corrugated sheets makes them easy to handle, transport, and install. Whether in packaging, construction, or agriculture, these sheets require minimal effort to put in place.

Environmental Impact of PP Corrugated Sheets

While plastic materials often raise concerns about environmental harm, PP corrugated sheets offer a more eco-friendly option compared to traditional single-use materials. Because they are fully recyclable, the impact of using polypropylene is minimized as the material can be reprocessed and used again. This circular use of resources helps reduce the overall environmental footprint of industries that rely on plastic.

Moreover, the long-lasting nature of PP corrugated sheets means they can be reused many times, further reducing waste. Industries that require durable, reusable solutions for packaging or protection can significantly lower their dependence on single-use materials by switching to PP corrugated sheets.

However, as with all plastics, proper disposal and recycling are essential to minimize environmental harm. If not correctly recycled, plastic materials can contribute to pollution and environmental degradation. It is crucial that PP corrugated sheets are disposed of responsibly to ensure they contribute to sustainability efforts.

Conclusion

PP corrugated sheets are a versatile, durable, and cost-effective solution for a wide range of applications across industries. From packaging to construction, these lightweight sheets offer exceptional strength and protection while being eco-friendly and fully recyclable. Their water resistance, impact resistance, and ease of customization make them an indispensable material in many sectors.

As industries continue to seek out sustainable and efficient solutions, Corrugated Plastic Sheets stand out as an excellent option, providing both environmental and economic benefits. With proper use and responsible recycling, PP corrugated sheets can contribute to a more sustainable and efficient future.

Frequently Asked Questions (FAQs)

Q1: Are PP corrugated sheets waterproof?

Yes, PP corrugated sheets are resistant to water and moisture, making them ideal for outdoor applications or in environments where water exposure is a concern.

Q2: Can PP corrugated sheets be printed on?

Yes, PP corrugated sheets can be easily printed on using a variety of techniques. This makes them popular for signage, advertising, and branding purposes.

Q3: How long do PP corrugated sheets last?

PP corrugated sheets are highly durable and can last for several years, especially when used in indoor applications or environments that do not expose them to extreme conditions.