3D Vapor Chamber Cooling: The Next Dimension in Heat Dissipation!

3D vapor chamber cooling offers advanced heat dissipation with multi-directional flow, keeping devices cooler, faster, and more efficient—ushering in the next level of thermal performance.

Share this Post to earn Money ( Upto ₹100 per 1000 Views )

Understanding Vapor Chamber Technology

What is a Vapor Chamber?

A vapor chamber is essentially a flat, sealed metal plate filled with a small amount of liquid—often water—that takes advantage of phase-change cooling. As heat is being shifted away from the source, the liquid in a chamber evaporates. This method makes it possible to quickly and uniformly distribute heat across the surface of the chamber.

How Traditional 2D Vapor Chambers Work

Everything takes place in two-dimensional vapor chambers. The chamber's base is directly in contact with the heat source, which is typically a CPU, GPU, or other high-performance component. The heat is spread across a flat surface as the liquid boils off, turning into vapor. While effective, the limitations arise when dealing with spatial constraints and multiple heat sources. There's only so much you can do in a flat space.

Common Use Cases in Modern Electronics

From high-performance laptops to gaming consoles, 2D vapor chambers are everywhere. They're favored for their passive operation (no fans or noise), slim profile, and reliability. But as electronics become more compact and powerful, there’s an urgent need for more advanced cooling techniques—hence the evolution toward 3D vapor chamber cooling.

The Evolution to 3D Vapor Chamber Cooling

From 2D to 3D – What Changed?

The move to 3D isn’t just a buzzword—it’s a structural transformation. Rather than confining heat transfer to a single plane, 3D vapor chamber cooling allows for vertical expansion. It creates a multidimensional heat path, utilizing stacked or contoured surfaces that can wrap around components, not just lie beneath them.

Structural Innovations in 3D Vapor Chambers

3D vapor chambers use intricate internal designs that include curved heat plates, customized vapor routes, and several layers of micro-structured wicks. These structures allow for better capillary action and more efficient return of condensed liquid to the heat source—meaning less heat retention and more effective cooling.

How 3D Chambers Increase Thermal Performance

Think of it like moving from a flat sponge to a three-dimensional one. More heat capacity, more surface area, and volume. The result? 3D chambers can manage higher thermal loads, cool multiple hot spots simultaneously, and function within smaller footprints—perfect for today’s miniaturized electronics.

Key Components of a 3D Vapor Chamber

Working Fluid and Phase Change

Phase change is still the technology's foundation. A tiny bit of liquid (usually purified water or a proprietary coolant) boils at a low temperature, turns into vapor, carries heat to a cooler area, and condenses. This closed-loop system is efficient, passive, and long-lasting.

Micro-Wicking Structures

Tricks are used to return the condensed liquid to the heat source. In 3D chambers, these wicks are built into multiple layers or stacked configurations, maximizing flow efficiency. Think of them like superhighways for heat and liquid movement.

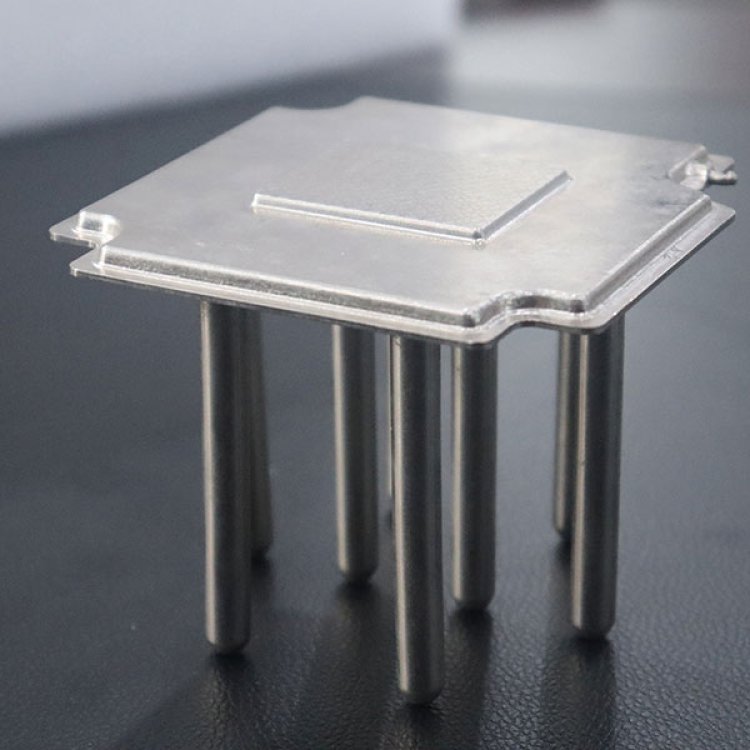

Vertical Heat Pipe Integration

Some 3D vapor chambers also integrate vertical heat pipes to create a hybrid system. These pipes help move heat up and away from the source, working in harmony with the chamber’s internal structures to distribute thermal energy evenly.

Multilayer Design Principles

By layering multiple chambers or adding vertical extensions, designers can customize chambers to fit around chips, battery modules, or uneven surfaces. This provides targeted cooling in complex configurations—a massive advantage for foldable phones, GPUs, and compact motherboards.

Benefits of 3D Vapor Chamber Cooling

Compact and Lightweight

Don’t be fooled by the complexity—3D vapor chambers are still thin and light enough to fit into ultra-slim laptops and mobile devices. They replace bulky heat sinks without adding much weight or thickness.

High Thermal Conductivity

With better liquid flow and more heat transfer paths, 3D designs drastically improve thermal conductivity. This means faster cooling and sustained peak performance, even under heavy loads like gaming or rendering.

Improved Heat Spreading and Management

No more hot spots. By allowing vapor to move in three dimensions, 3D chambers ensure even heat distribution. This extends the life of components and boosts device reliability.

Versatility in Small Devices

Whether it’s a smartwatch, foldable phone, or compact drone, 3D chambers can be tailored to fit non-standard shapes and work within extremely tight spaces, without compromising cooling capacity.

Real-World Applications

Gaming Laptops and GPUs

Graphics-intensive tasks generate tons of heat. 3D vapor chambers allow gaming rigs to remain slim while delivering desktop-grade performance. GPUs like the RTX 4090 are exploring this tech for better heat spread.

Foldable and Ultra-Thin Smartphones

Traditional cooling methods simply don’t fit in foldable designs. 3D chambers can wrap around hinge mechanisms or fit into curved shells, providing consistent cooling across an irregular surface.

Data Centers and Server Farms

In environments where uptime and thermal efficiency are everything, 3D vapor chambers reduce the reliance on energy-hungry fans or liquid cooling. They help servers stay cool passively, even in stacked configurations.

Electric Vehicles and Battery Systems

Vapor chamber cooling is very beneficial for both onboard CPUs and EV batteries. With their layered cells and compact layouts, 3D cooling allows for even heat dissipation without increasing bulk.

Comparing 3D Vapor Chamber Cooling with Other Technologies

3D Vapor Chamber vs. Traditional Heat Pipes

For many years, the recommended option was heat pipes. Despite their dependability and affordability, they have limited flexibility and may not work well with contemporary device layouts. In contrast, 3D vapor chambers are much more effective in multi-point heat scenarios, provide more constant heat distribution, and are more versatile.

3D Vapor Chamber vs. Liquid Cooling

Liquid cooling systems use pumps, tubes, and radiators—making them bulky, maintenance-heavy, and prone to leaks. 3D vapor chambers, on the other hand, are entirely passive. They need no maintenance, are leak-proof, and offer near-silent operation. Ideal for laptops, tablets, and electronic systems that are sealed.

3D Vapor Chamber vs. 2D Vapor Chamber

While 2D chambers are great for flat, single-source cooling, 3D designs are game-changers when space and multi-source cooling are involved. Think of 2D as a pancake and 3D as a layer cake—the latter offers more utility, depth, and performance.

What 3D Vapor Chambers' Future holds

Wider Adoption in Consumer Electronics

From smartphones to wearables, expect to see more 3D vapor chamber tech being integrated into everyday devices. As more brands realize the performance gains, the shift will be inevitable.

Next-Level Gaming and VR Hardware

High-resolution VR and AR headsets demand serious processing power in small form factors. 3D vapor chambers are the perfect match, keeping headsets cool and comfortable during extended use.

Smarter Integration with AI and IoT Devices

AI workloads generate significant heat, even in small edge devices. 3D vapor cooling can keep these units performing optimally in harsh or space-constrained environments.

Breakthroughs in Multi-Layer Materials

Future innovations may involve advanced composite materials and nanotechnology, allowing vapor chambers to become even thinner, faster, and more adaptable to new electronics.

When it comes to heat dissipation, we’re entering a new era—and 3D vapor chamber cooling is leading the charge. As electronics continue to get smaller, faster, and more complex, traditional cooling methods simply won’t cut it anymore. That’s where 3D vapor chambers shine.

From their ability to cool multiple heat sources simultaneously to their slim, adaptable designs, they’re revolutionizing thermal management in consumer electronics, gaming, automotive tech, and beyond.

For companies like Tone Cooling Technology Co., Ltd., this isn't just an upgrade—it's a commitment to performance, sustainability, and innovation. If you’re building the next-gen device and want to keep it cool, quiet, and efficient, 3D vapor chamber cooling should be at the top of your list.

FAQs

1. What is 3D vapor chamber cooling's main benefit?

The main advantage is its ability to dissipate heat in multiple directions, which allows for more effective and uniform cooling—especially in compact, high-performance devices.

2. Are 3D vapor chambers better than heat pipes?

Yes. While heat pipes work well, they’re limited to linear pathways. 3D vapor chambers offer more flexibility, better thermal conductivity, and are suitable for complex device layouts.

3. Can I install a 3D vapor chamber in my current laptop?

Unfortunately, most 3D vapor chambers are built-in during the device’s manufacturing process. They aren’t modular or user-installable like fans or heat sinks.

4. What is the lifespan of a 3D vapor chamber?

If properly manufactured, they can last as long as the device itself—often 5 to 10 years or more—since there are no moving parts and minimal risk of failure.

5. Why should I choose Tone Cooling Technology Co., Ltd for 3D vapor chamber solutions?

Tone Cooling combines cutting-edge R&D, custom engineering, and sustainable practices to deliver reliable, high-performance thermal solutions tailored to your device’s needs.

liquidcoldplatemanufacturer

liquidcoldplatemanufacturer